Upgrading and heat supply system for steam turbine exhaust steam waste heat

A technology of heating system and steam turbine, which is used in heating system, hot water central heating system, household heating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

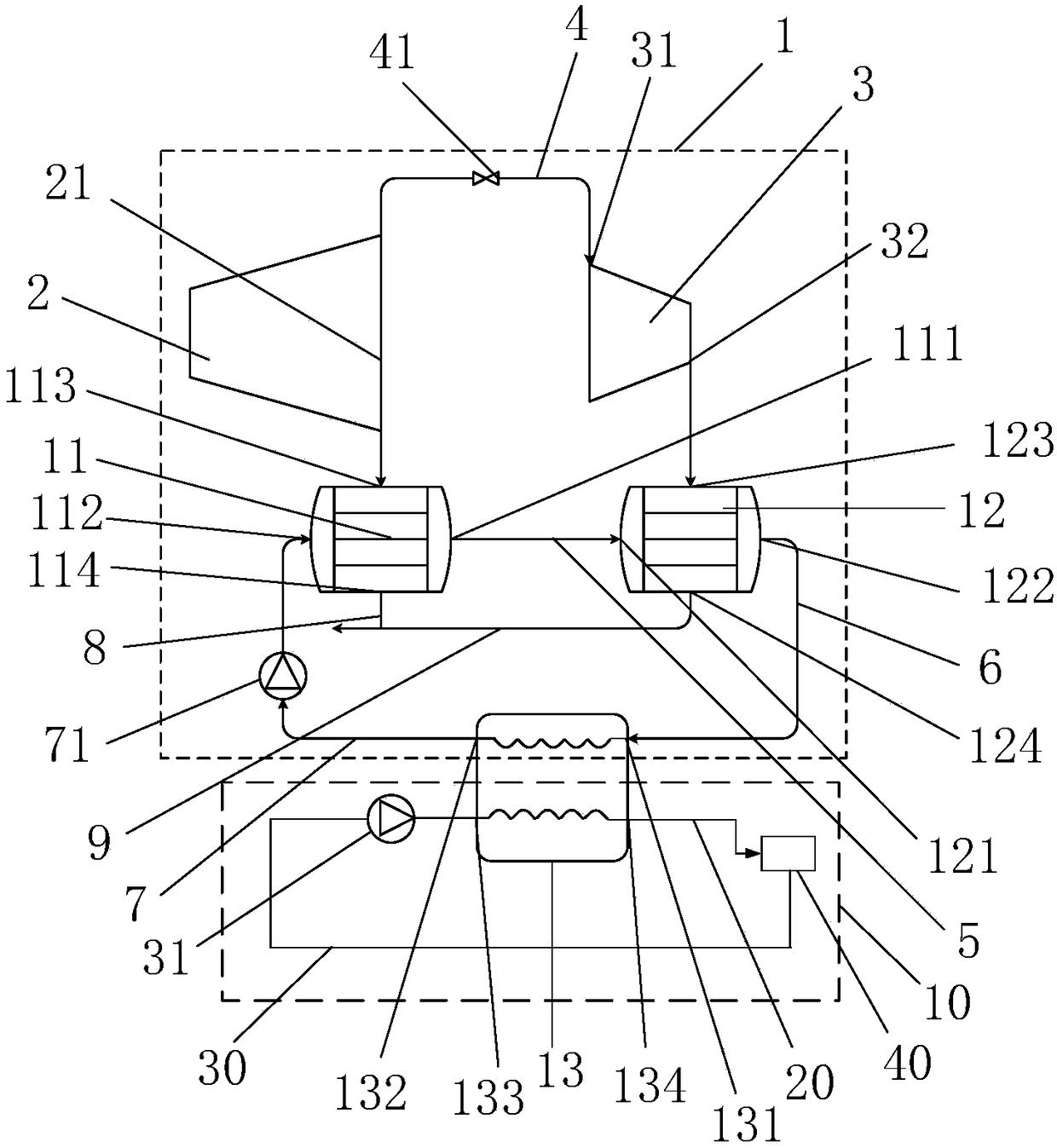

[0027] Such as figure 1 As shown, the figure schematically shows that the steam turbine exhaust steam waste heat quality improvement heating system includes the heat network primary heating circuit 1, steam turbine 2 and a compressor 3 capable of reheating and pressurizing excess exhaust steam .

[0028] In the embodiment of the present application, the primary heat supply circuit 1 of the heating network includes a first heat exchanger 11, a second heat exchanger 12, and a third heat exchanger 13, wherein one of the first heat exchanger 11 The secondary heating network water outlet 111 of the stage heating network communicates with the secondary heating network water inlet 121 of the second heat exchanger 12, and the secondary heating network water outlet 122 of the second heat exchanger 12 communicates with the third heat exchanger 13 The first water inlet 131 of the third heat exchanger 13 is in communication with the first water outlet 132 of the third heat exchanger 13 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com