Modified polyvinyl chloride material and its preparation method

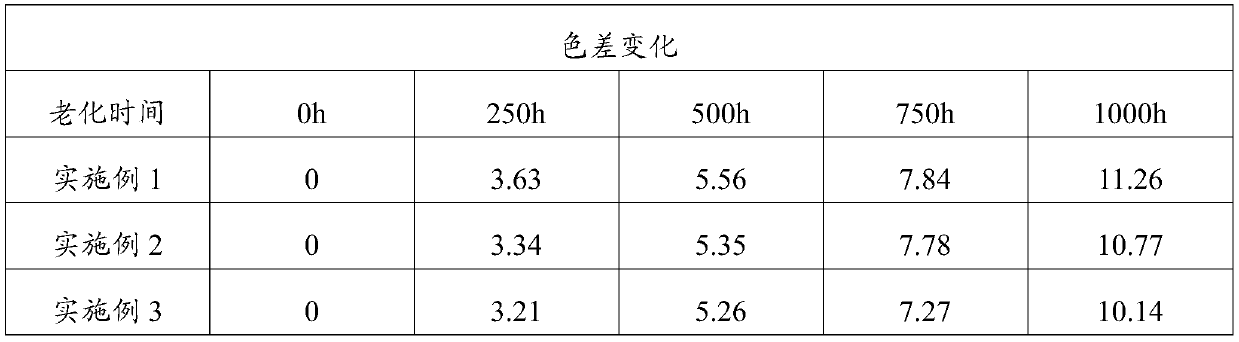

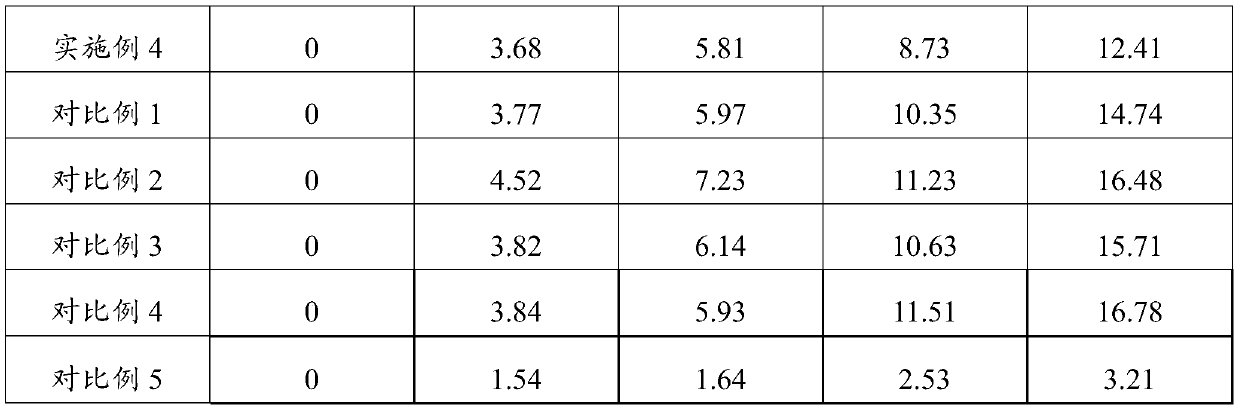

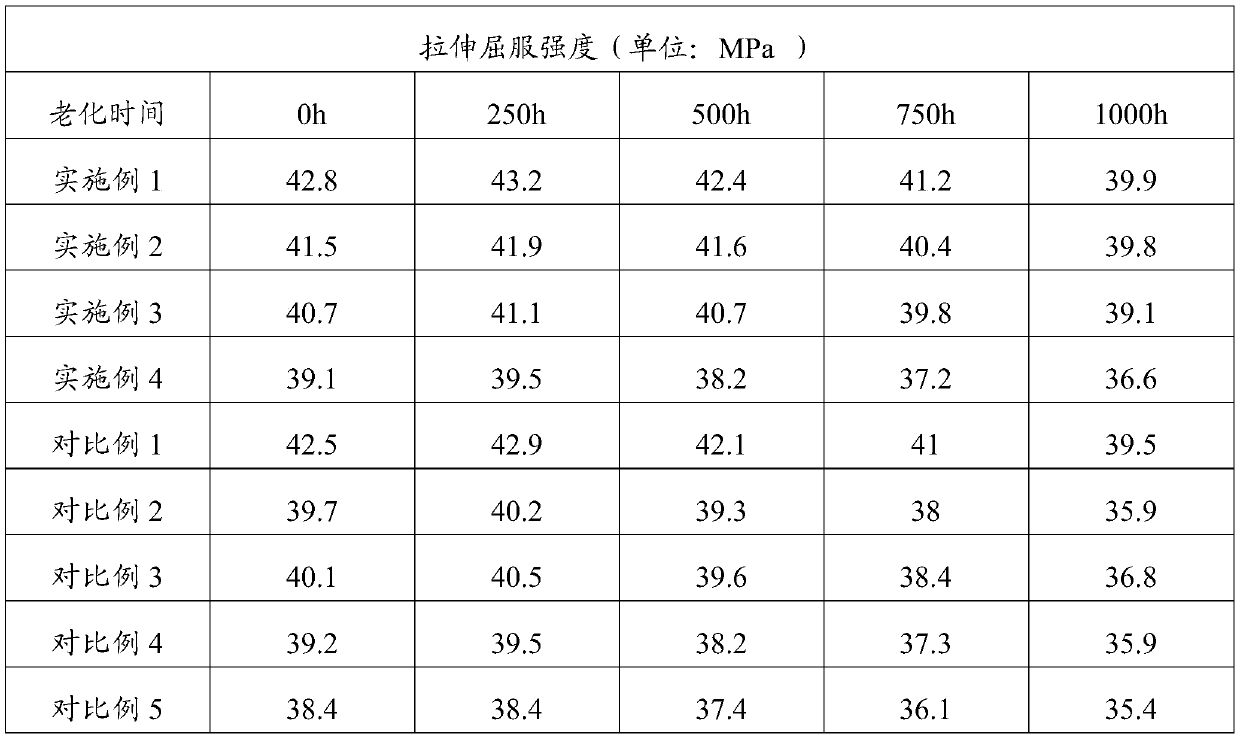

A polyvinyl chloride, modified technology, applied in the field of materials, can solve the problems of physical and mechanical performance decline, affect customer use, aging and discoloration, etc., achieve the effect of small change in mechanical properties, not easy to decompose, aging and discoloration, and prolong life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] A method for preparing a modified polyvinyl chloride material according to an embodiment of the present invention includes the following steps S1-S2:

[0021] S1. Mix titanium dioxide and carbon black and heat up to 60-80°C, then add titanate coupling agent, stir for 10-20 minutes, dry and grind to obtain a weather resistance additive with a particle size below 100nm, titanium dioxide, carbon black The mass ratio with the titanate coupling agent is 4-7:2-5:1.

[0022] In one embodiment, the mass ratio of titanium dioxide, carbon black and titanate coupling agent is 6:3:1, this ratio can obtain better performance relative to other ratios, and carbon black and titanium dioxide have a synergistic effect, but It is not advisable to add too much carbon black, otherwise it will easily lead to a decrease in the mechanical properties of the modified polyvinyl chloride material.

[0023] S2. Mix polyvinyl chloride, auxiliary materials and weather resistance additives, and then ...

Embodiment 1

[0033] Add 6kg of titanium dioxide and 3kg of carbon black to the high-speed stirring equipment, stir and gradually raise the temperature to 70°C, add 1kg of titanate coupling agent, then stir for 10-20min, take it out and dry it, put it into a grinder and grind it to obtain granules Weather resistance additives with a diameter below 100nm.

[0034] Stir 2kg of weathering aid and 100kg PVC in a high-speed mixer at a low speed (below 100r / min) for 5min, then add 4kg of calcium-zinc stabilizer, 15kg of active calcium carbonate, 2kg of internal lubricant and external lubricant to obtain a mixture. Stir at ~1500r / min until the temperature of the mixture reaches 120°C, then put the mixture into the cold mixing equipment and stir at 500r / min until the temperature of the mixture drops to 40-50°C, then extrude Modified polyvinyl chloride material pipes can be obtained by machine extrusion.

Embodiment 2

[0036] Add 6kg of titanium dioxide and 3kg of carbon black to the high-speed stirring equipment, stir and gradually raise the temperature to 70°C, add 1kg of titanate coupling agent, then stir for 10-20min, take it out and dry it, put it into a grinder and grind it to obtain granules Weather resistance additives with a diameter below 100nm.

[0037] 6kg of weathering aid and 100kg of PVC were stirred at a low speed (below 100r / min) for 5min in a high-speed mixer, then 4kg of calcium-zinc stabilizer, 15kg of active calcium carbonate, 2kg of internal lubricant and external lubricant were added to obtain a mixture. Stir at ~1500r / min until the temperature of the mixture reaches 120°C, then put the mixture into the cold mixing equipment and stir at 500r / min until the temperature of the mixture drops to 40-50°C, then extrude Modified polyvinyl chloride material pipes can be obtained by machine extrusion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com