Multi-axial fatigue life prediction model

A fatigue life prediction and model technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems that various materials cannot be widely used, and the impact cannot be fully considered, so as to achieve wide material adaptability and wide material Applicability, high-precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

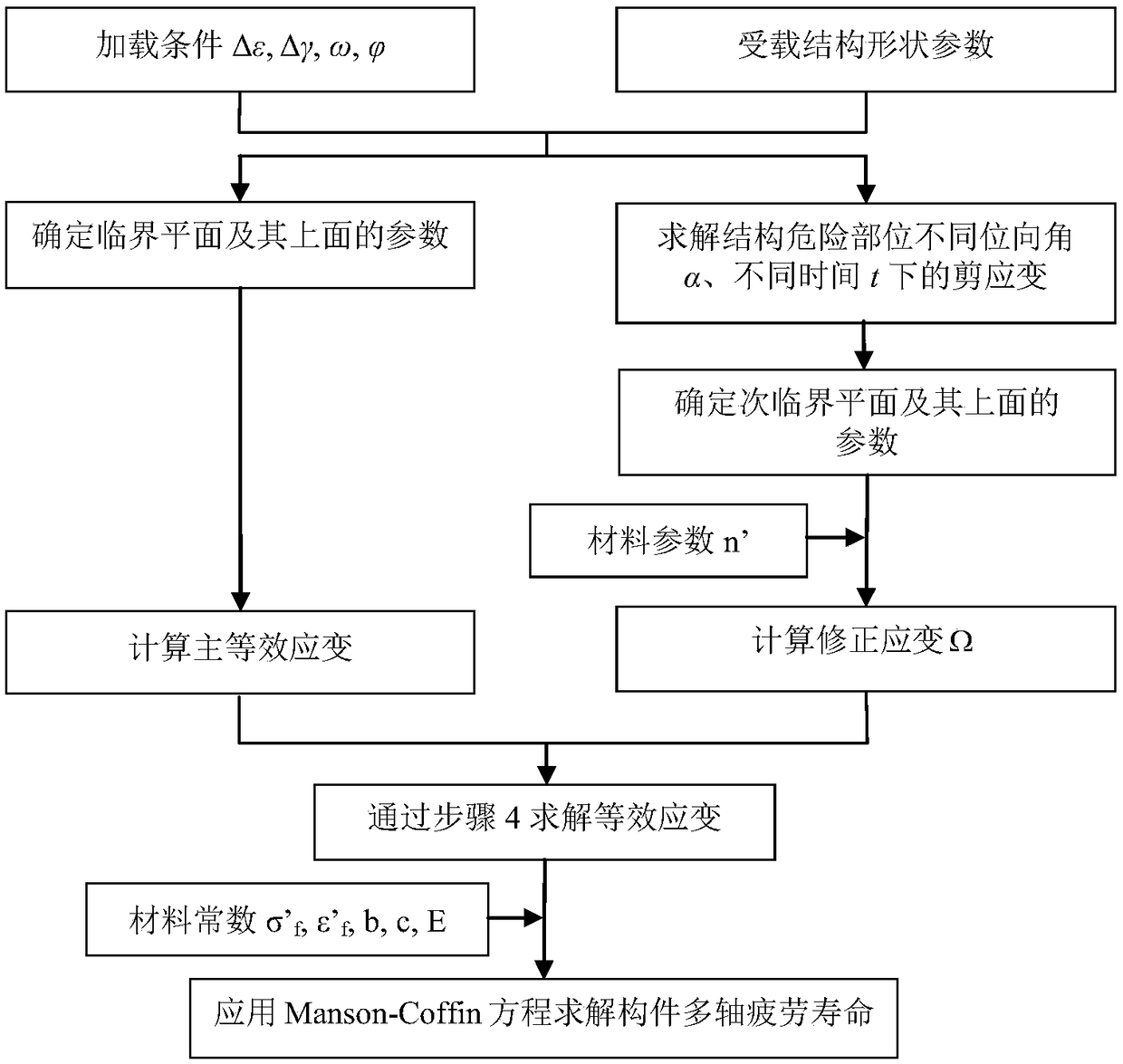

[0041] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

[0042] Such as image 3 Shown, a kind of multiaxial fatigue life prediction method of the present invention comprises the following steps:

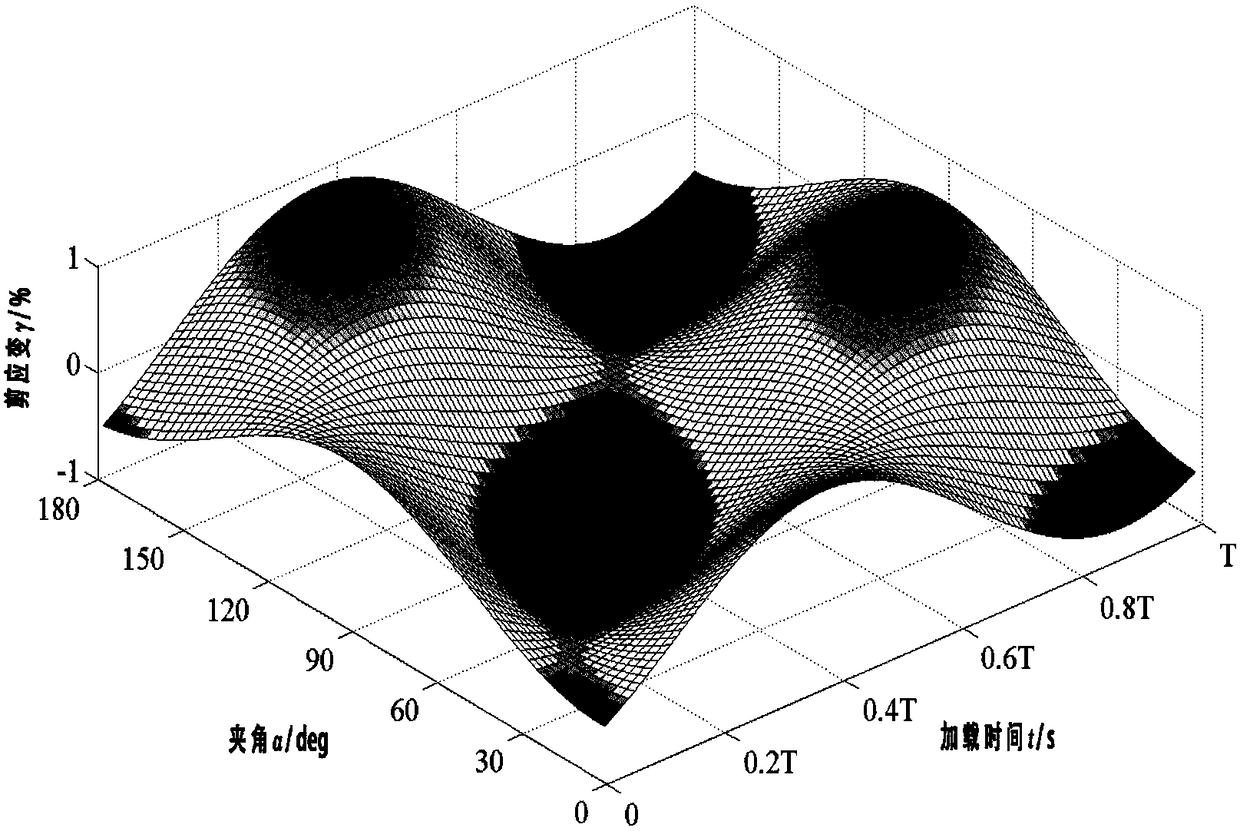

[0043] 1) Using finite element analysis to solve the shear strain of the dangerous part of the thin-walled member at different orientation angles α and at different times t, and obtain the change history diagram of the shear strain of the dangerous part of the thin-walled member;

[0044] 2) Through the above change history diagram, the plane where the maximum shear strain amplitude is located is obtained, and this plane is defined as the main critical plane, and the orientation angle of this plane is defined as α max ;

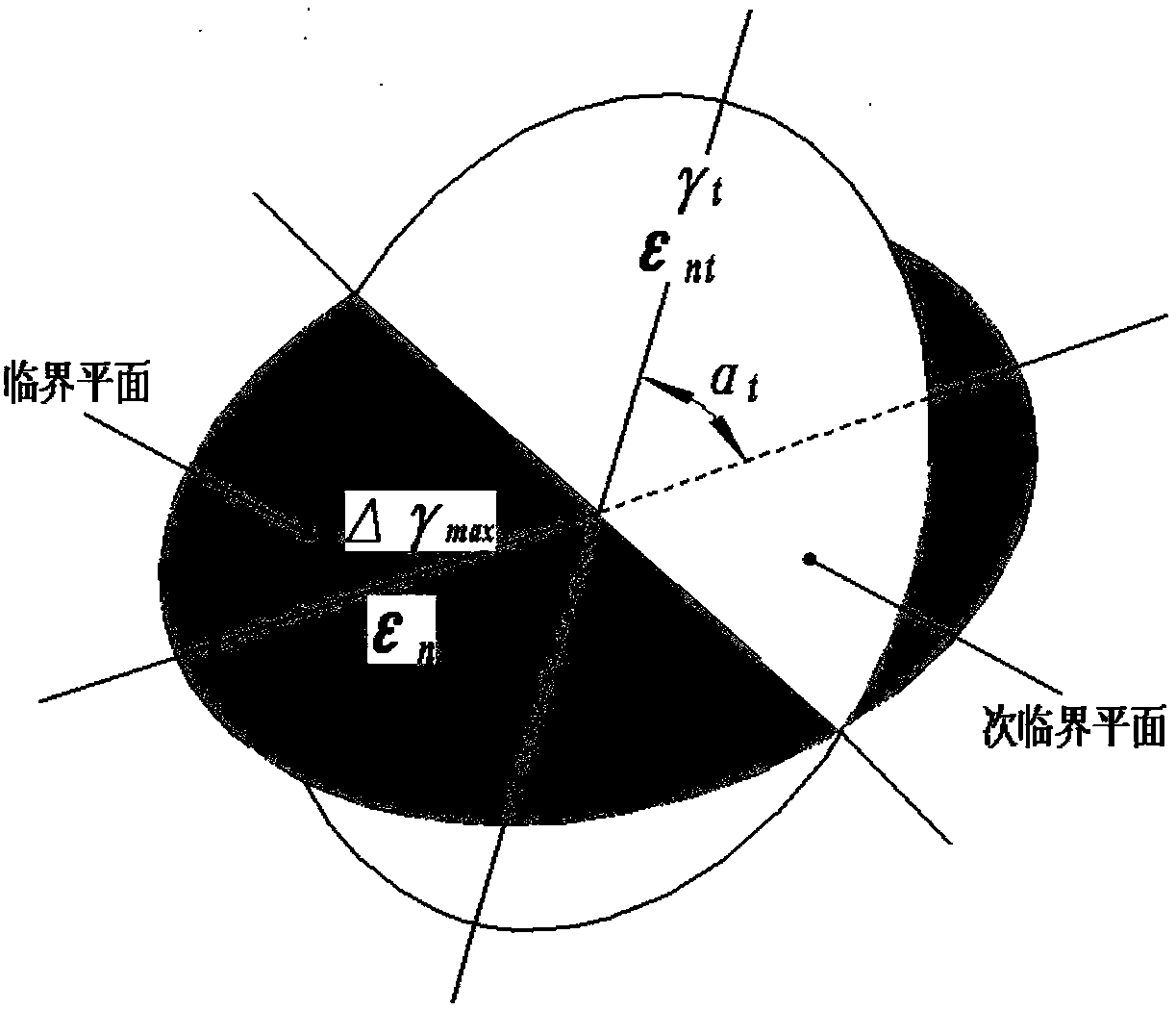

[0045] 3) Define any time t, and obtain the plane where the maximum shear strain is located at this time through the above-mentioned change history diagram, define this plane as the subcriti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com