Rapid installation structure of building heat insulation board

A technology for building thermal insulation and installation structure, which is applied in the direction of building components, building structure, thermal insulation, etc. It can solve the problems that the thermal insulation board cannot be disassembled, the connection structure is complicated, time-consuming and labor-intensive, etc., and achieves good disassembly or installation applicability and tilting support strength High, time-saving and labor-saving installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

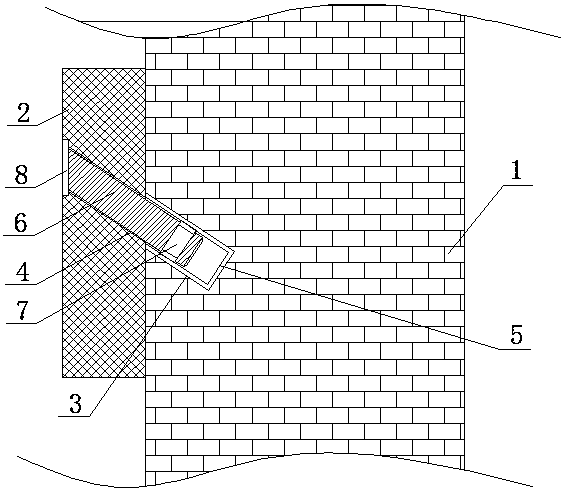

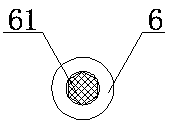

[0013] Such as Figure 1-2 As shown, the present invention discloses a quick installation structure of a building insulation board, including a building wall 1, a heat preservation board 2, a pre-buried hole 3, an inclined through hole 4, a pre-buried pipe 5, a screw rod 6, a nut 7, a rubber plug Head 8, a thermal insulation board 2 is installed on the side wall of the building wall 1, and a pre-embedded hole 3 is opened on the side of the building wall 1 in contact with the thermal insulation board 2, and the pre-embedded hole 3 is inclined The hole groove opened in the state, and the pre-embedded pipe 5 is fastened and loaded in the pre-embedded hole 3 provided, and the nut 7 is welded and fixed in the pre-embedded pipe 5 .

[0014] The insulation board 2 is provided with an inclined through hole 4, and a screw 6 is installed in the inclined through hole 4, and the inclined bottom end of the screw 6 is threaded and tightened with the nut 7 provided in the pre-embedded pipe 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com