Packaging structure and manufacturing process of packaging structure

A technology of packaging structure and manufacturing process, applied in the field of packaging structure and manufacturing process of packaging structure, can solve problems such as affecting the aesthetics of packaging structure, generating burrs, hidden safety hazards, etc., to prevent shredding or generating burrs, ensure appearance, and eliminate The effect of security risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

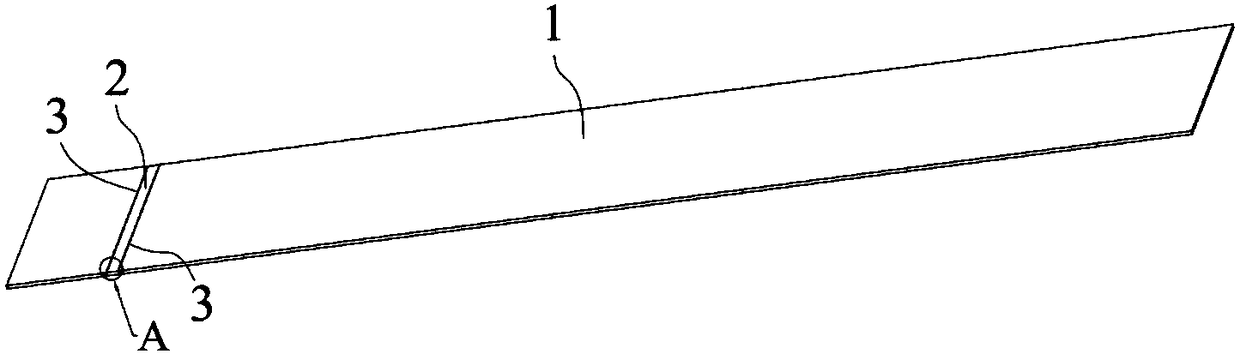

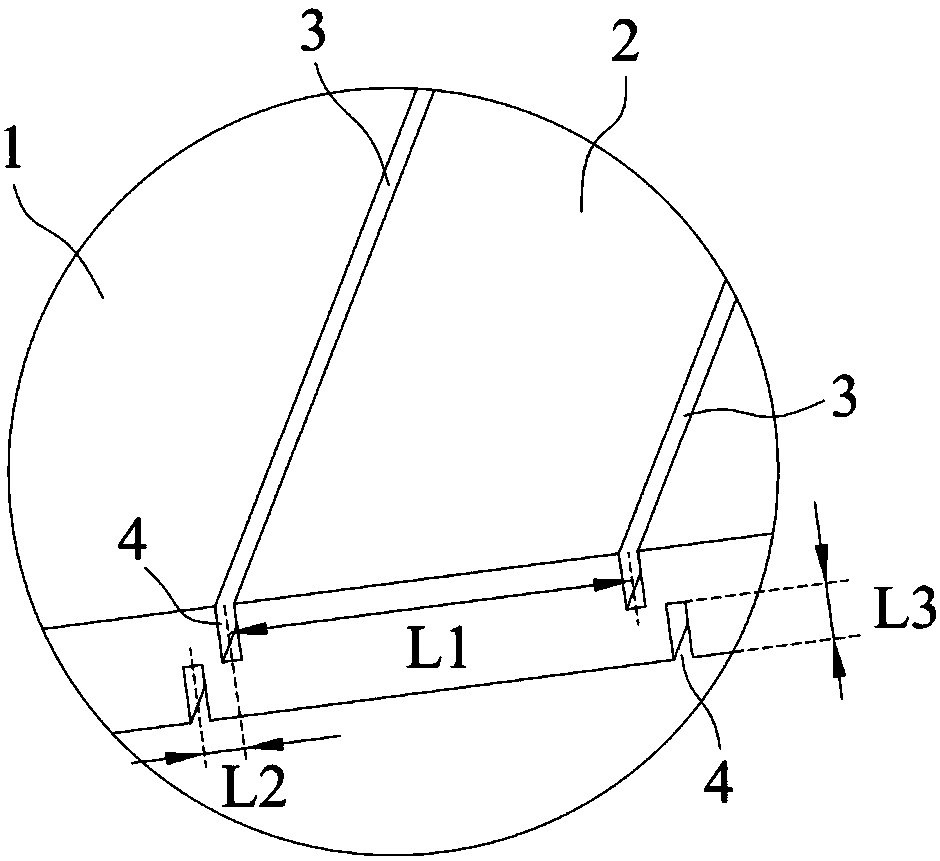

[0035] This embodiment protects a packaging structure, which is usually a paper packaging structure such as a packaging box or a packaging bag, such as figure 1 and figure 2 As shown, the packaging structure 1 is provided with a tear strip 2, which is used to open the sealed packaging box or packaging bag by tearing the tear strip 2, and the setting of the tear strip 2 is convenient for the user to operate. The front and back sides of the tear strip 2 are respectively provided with tear lines 3 at intervals. The tear line 3 is a positive and negative half-through structure. The tear line 3 on the front side of the tear strip 2 is staggered from the tear line 3 on the back side, and the tear line 3 on the back side is located on the front side. The outer side of the tear pull wire 3. Tear line 3 can be straight line also can be curve.

[0036] The packaging structure 1 sets the front and back of the tear strip 2 at intervals with the front and back half-through structure tea...

Embodiment 2

[0045] The difference between this embodiment and Embodiment 1 is that, if Figure 7 As shown, the end of the tear strip 2 is provided with a tear portion 5 . The setting of the tearing portion 5 is convenient for the user to tear the tear strip 2 . Preferably, the two ends of the tear strip 2 are provided with a tear part 5, and when the tear part 5 at one end of the tear strip 2 is torn during the tearing process, if the tear strip 2 is broken, the other end can be The tear strip 2 is torn off by the tear part 5, which is convenient for the user to operate. The tear part 5 has any shape. The packaging structure 1 is provided with a notch 11 at the position where the tear part 5 is provided, and the notch 11 is provided for easy operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com