Injector packing machine

A syringe and packaging machine technology, applied in the field of machinery, can solve the problems of syringe pollution and low packaging efficiency, and achieve the effects of accurate and reliable movement, improved work efficiency, and reduced adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

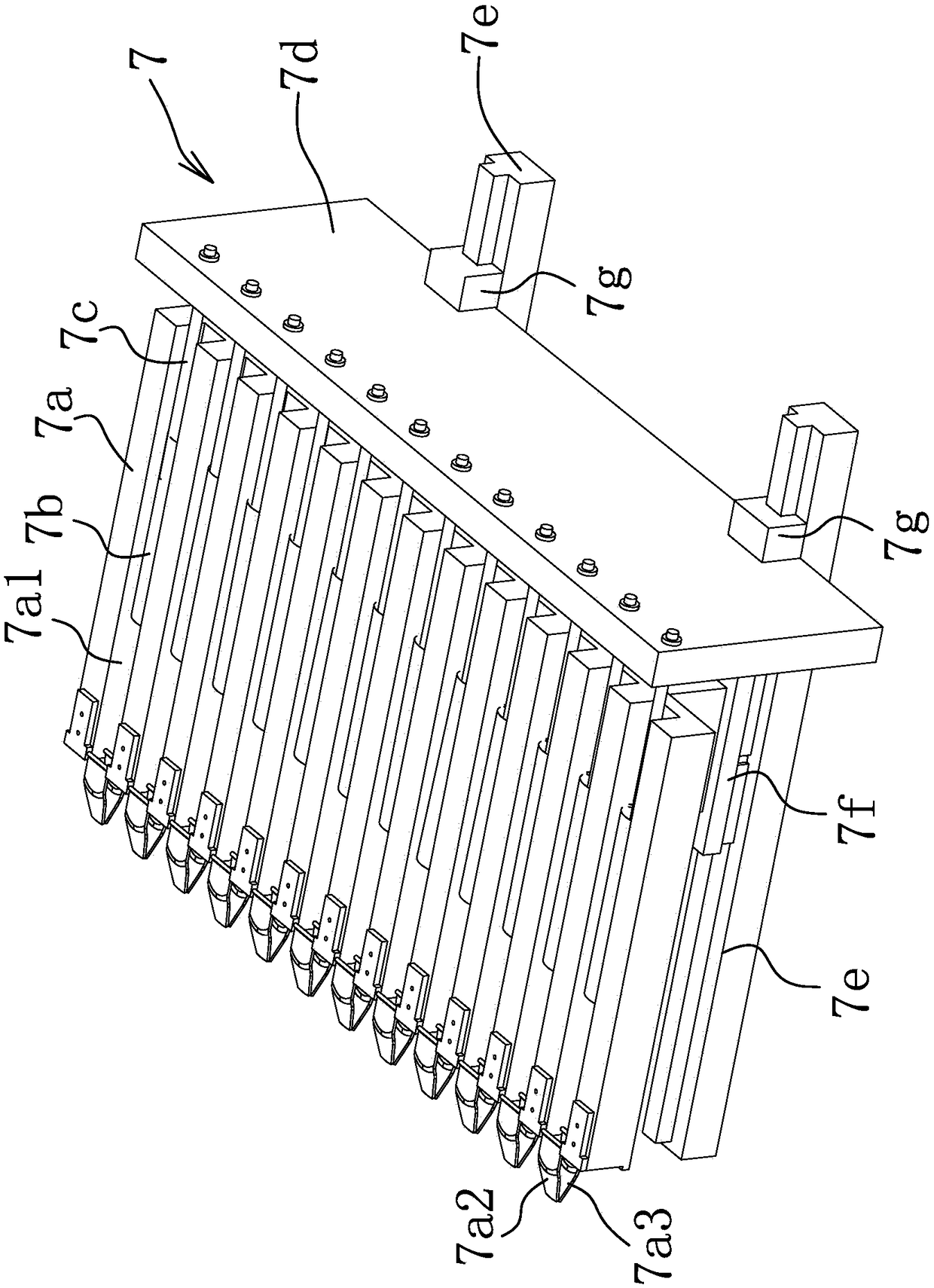

[0039] Such as figure 1 As shown, a syringe packaging machine includes a workbench 3 on which a syringe 1 unloading mechanism, a syringe retrieving mechanism 5 and a syringe conveying mechanism 6 are arranged. The feeding mechanism of the syringe 1 includes a turntable, and a plurality of fixing grooves are arranged on the outer periphery of the turntable. The syringe conveying mechanism 6 includes a synchronous belt arranged on one side of the turntable, and the synchronous belt is driven by the syringe 1 conveying motor. A fixed frame is fixed on the workbench 3, and a translation frame is slidably connected to the fixed frame. A syringe 1 translation cylinder is arranged between the translation frame and the fixed frame. The syringe 1 translation cylinder drives the translation frame to move longitudinally forward and backward. Cylinder, the piston rod of the injector 1 lifting cylinder is set downwards and is fixed with the injector 1 sucker, and the injector 1 sucker is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com