Air outlet blade turbulence structure and air outlet system

A technology of air outlet and blades, which is applied in the field of air outlet blade spoiler structure and air outlet system, which can solve the problems of high cost and achieve the effects of no increase in leakage, no increase in cost per part, and no increase in difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

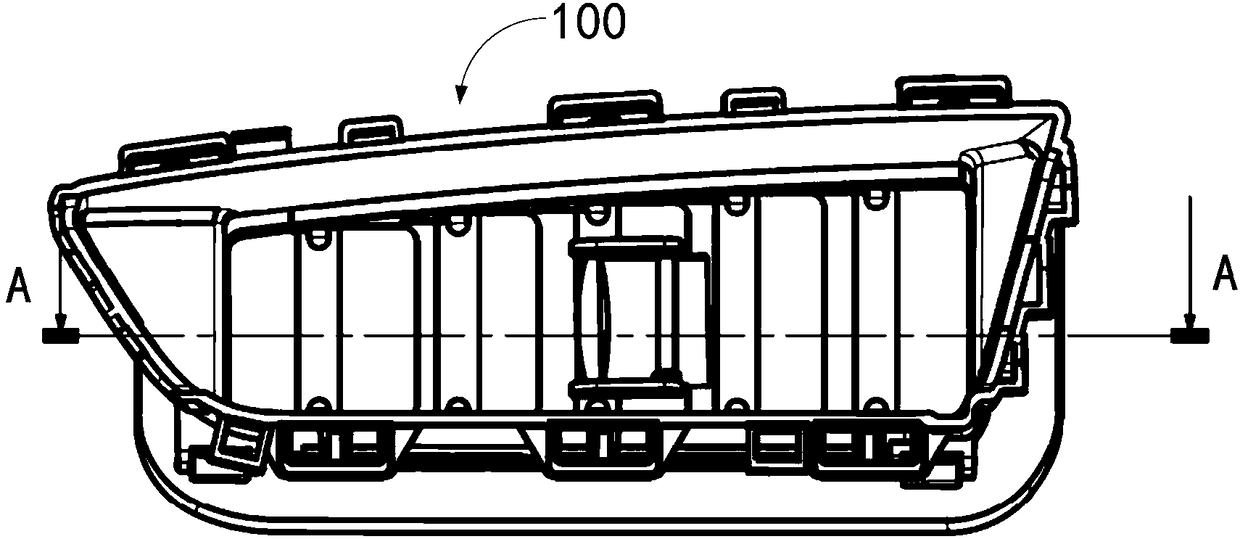

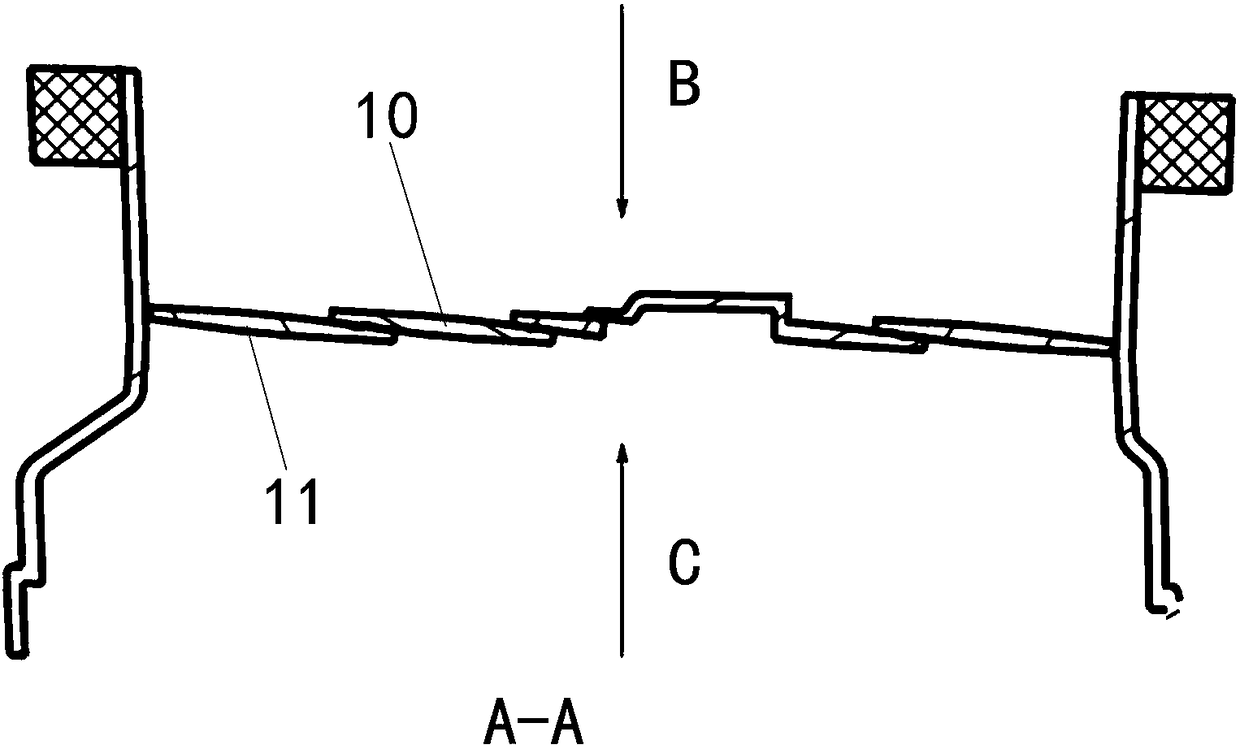

[0047] Such as Figure 1-Figure 6 As shown, the air outlet vane turbulence structure 100 provided in this embodiment includes a first vane 10 and a second vane 11;

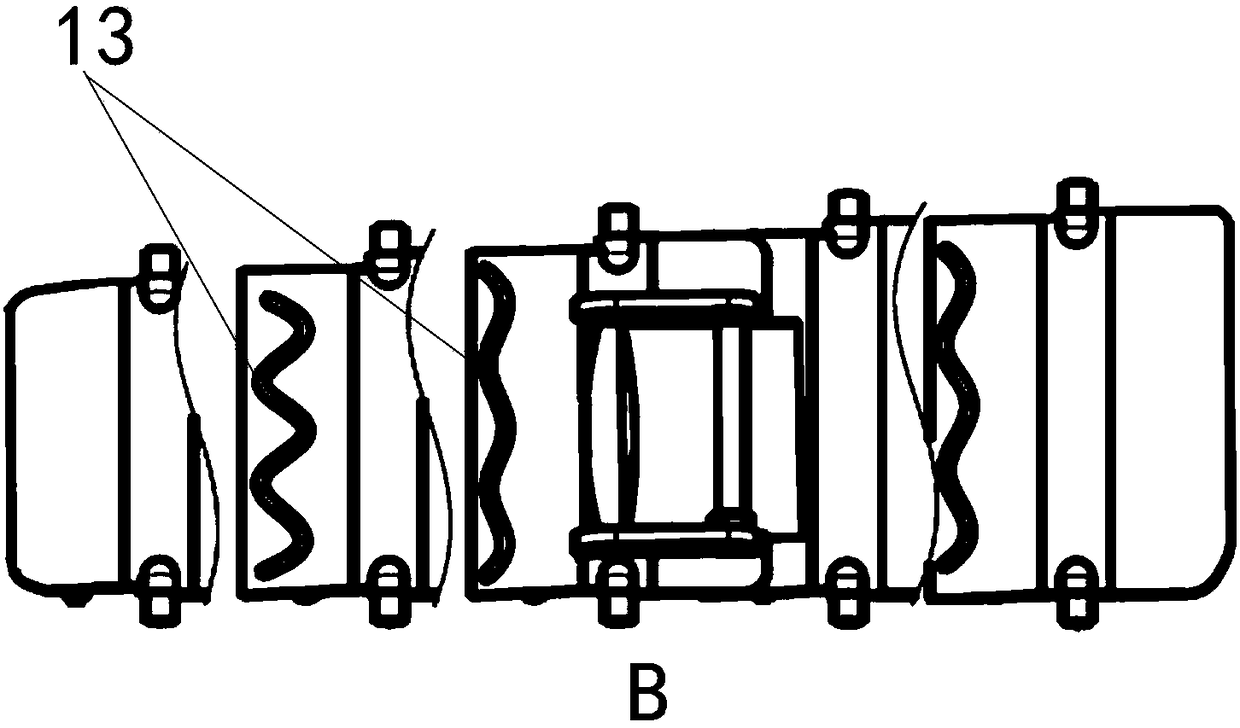

[0048] The first vane 10 is located above the second vane 11, and there is a gap between the first vane 10 and the second vane 11; the first vane 10 is provided with a first guide groove 12, so The second vane 11 is provided with a second guide groove 13 .

[0049] Specifically, through the turbulence method of the diversion groove, while improving the howling problem, the air leakage will not increase. In terms of user sensory needs, it has better quality performance and can meet the comfort of customers.

[0050] On the basis of the above examples, if Figure 2-Figure 4 As shown, the first diversion groove 12 and the second diversion groove 13 are intersected.

[0051] As an optional implementation manner, the first diversion groove 12 and the second diversion groove 13 are S-shaped grooves.

[0052]The firs...

Embodiment 2

[0066] Embodiment 2 of the present invention provides an air outlet system, including the air outlet vane spoiler structure 100 described in any technical solution of Embodiment 1 above.

[0067] The air outlet system provided by Embodiment 2 of the present invention is provided with the air outlet vane turbulence structure provided by Embodiment 1, so it has all the beneficial effects of the air outlet blade turbulence structure provided by Embodiment 1, and will not go into details here. .

[0068] Specifically, in order to solve the problem of air leakage in the prior art, major OEMs are reducing the air leakage problem by adjusting the peripheral contour of the blades. Since the shrinkage, deformation and other problems unique to injection molded parts cannot be 100% controlled, therefore, When the cross-sectional area caused by the air flow velocity and the peripheral gap reaches a certain value when the blade is closed, howling will occur; users cannot accept the howling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com