Packaging equipment, sleeving and shrinking machine and packaging method for performing continuous and automatic mesh sleeving of sausage casings

A technology of packaging equipment and a packaging method, which is applied to the shirring of sausage casings, sausage casings, and production of sausage casings, etc., which can solve the problems that cannot be carried out in a good connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

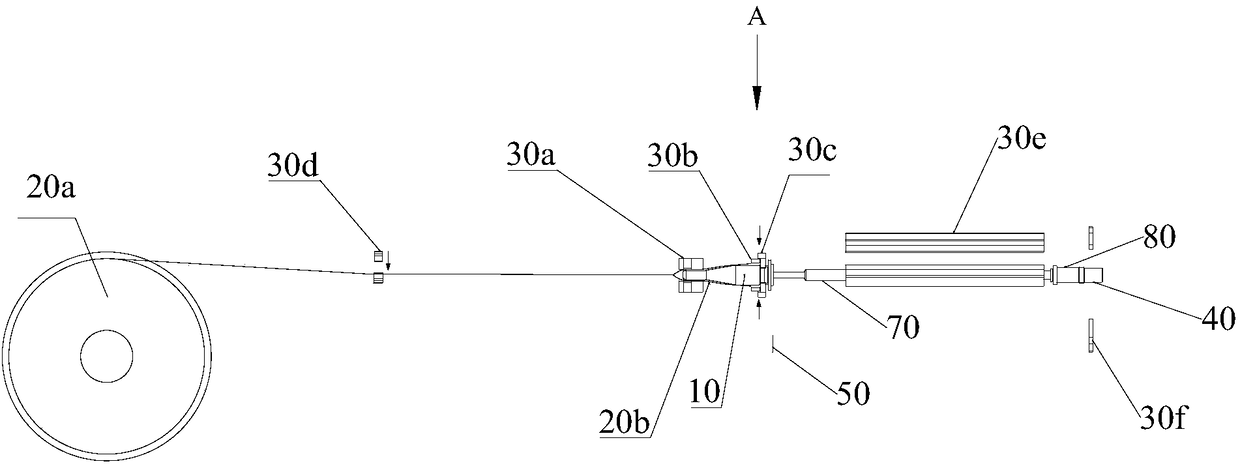

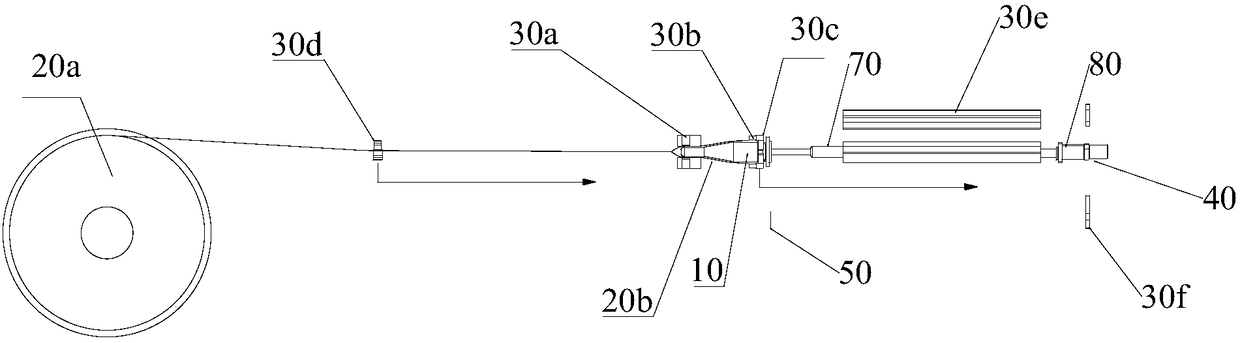

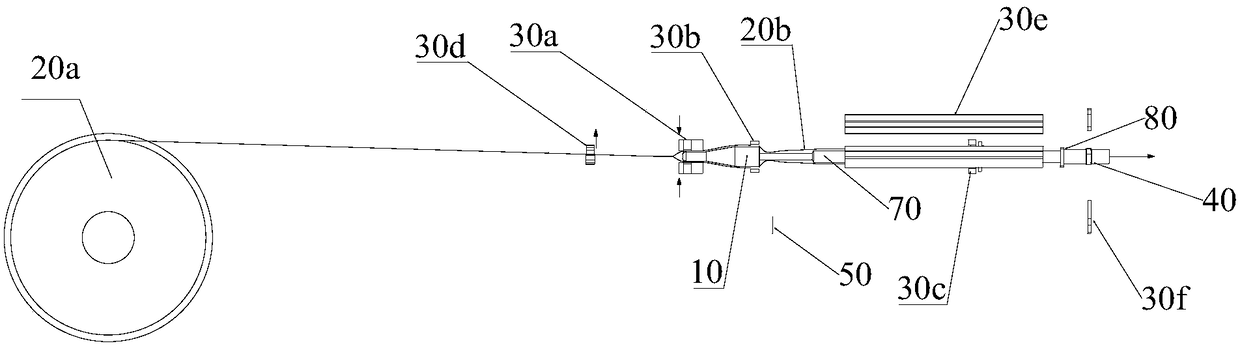

[0036] The packaging equipment, shrinking machine and casing packaging method of the present invention will be described in detail in conjunction with the accompanying drawings. It should be noted that the accompanying drawings are only for illustration and should not be construed as limitations of the present invention.

[0037] Figures 1a-1i as well as Figure 2a-2i It shows the structural diagrams of different working states of the automatic net bag packaging device. Such as Figures 1a-1i as well as Figure 2a-2i Shown, the present invention is used for the packaging equipment of casing casing continuous automatic netting has: shuttle 10, and the outer peripheral surface 12 of this shuttle 10 is designed to be suitable for the net bag 20b that pulls out from net bag volume 20a to be set on the shuttle 10 One end of the shuttle 10 away from the net bag roll 20a is provided with an accommodation hole 14; the first gripper 30a, which can be opened or closed so as to relea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com