An electronic crane scale automatic detection device

A technology of automatic detection device and electronic crane scale, which is applied in the direction of measuring device, weighing equipment test/calibration, detailed information of weighing equipment, etc., can solve the problems of detection result error, many weight loading points, error, etc., to achieve Efficiency improvement, rich combination, stable and consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

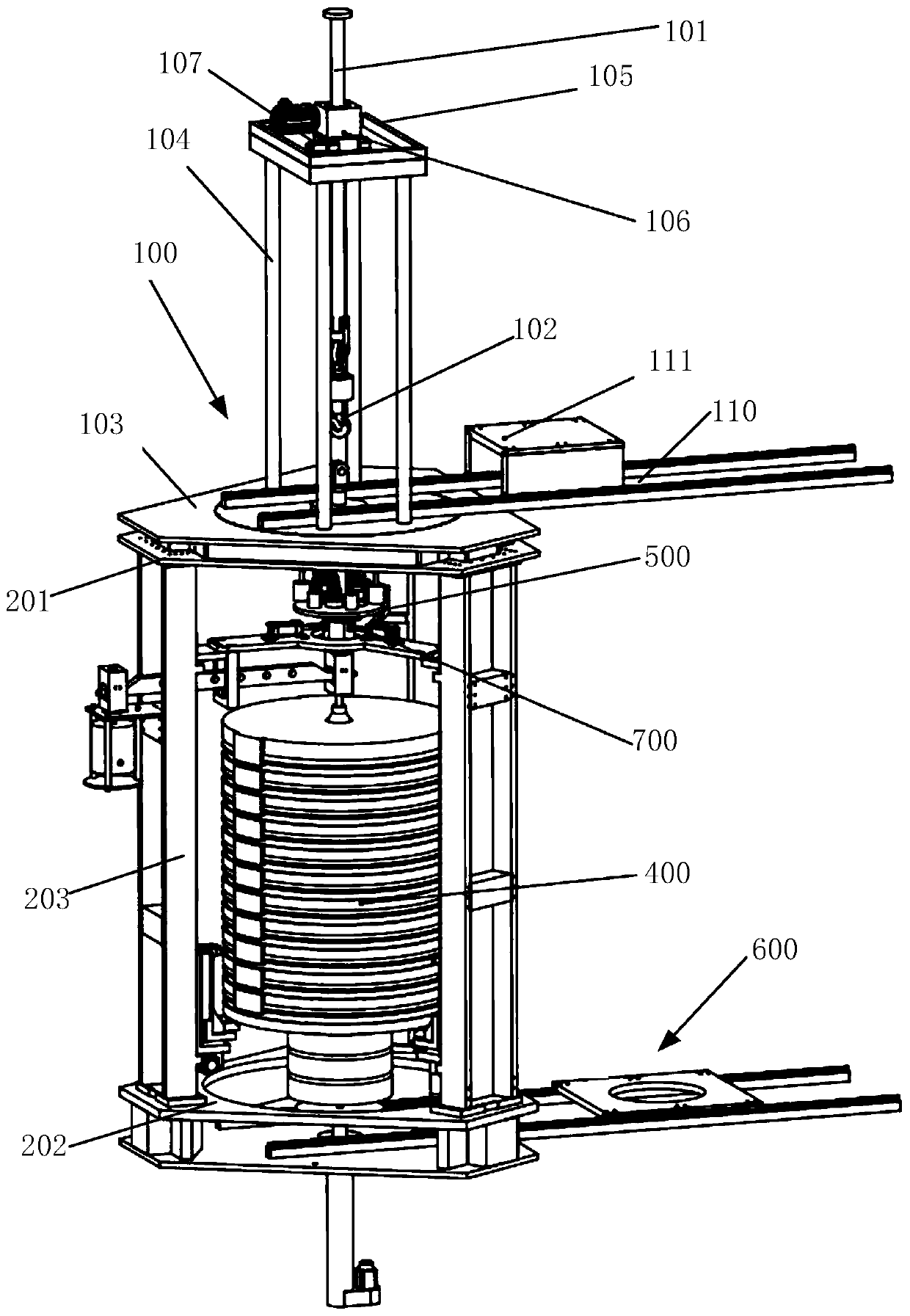

[0053] Such as Figure 1-Figure 2 As shown, the present invention provides an automatic detection device for an electronic hanging scale, including: a hanging mechanism 100, a weight connection device, a weight loading system 400, a discrimination threshold detection device 500, a weight removal device 600 and a main frame; wherein :

[0054] The main frame includes a main frame top plate 201 , a main frame base 202 , and a main frame support 203 ; the main frame support 203 is respectively connected with the main frame top plate 201 and the main frame base 202 . There are at least three main frame pillars 203 .

[0055] The hanging mechanism 100 is arranged above the main frame; the hanging mechanism 100 includes a hook driving device, a driving rod 101 and a hook 102; the hook 102 is connected with the driving rod 101, and the driving rod 101 is driven by the hook Action driven by the device.

[0056] It should be noted that the hook 102 is the hook 102 of the electronic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com