An integrally assembled power cabin of a super-large tonnage hydraulic excavator

A technology for hydraulic excavators and super-large tonnage, which is applied to earth movers/excavators, construction, etc., and can solve the problems of difficulty in welding deformation control, precision assurance, and convenience of disassembly and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with specific embodiments.

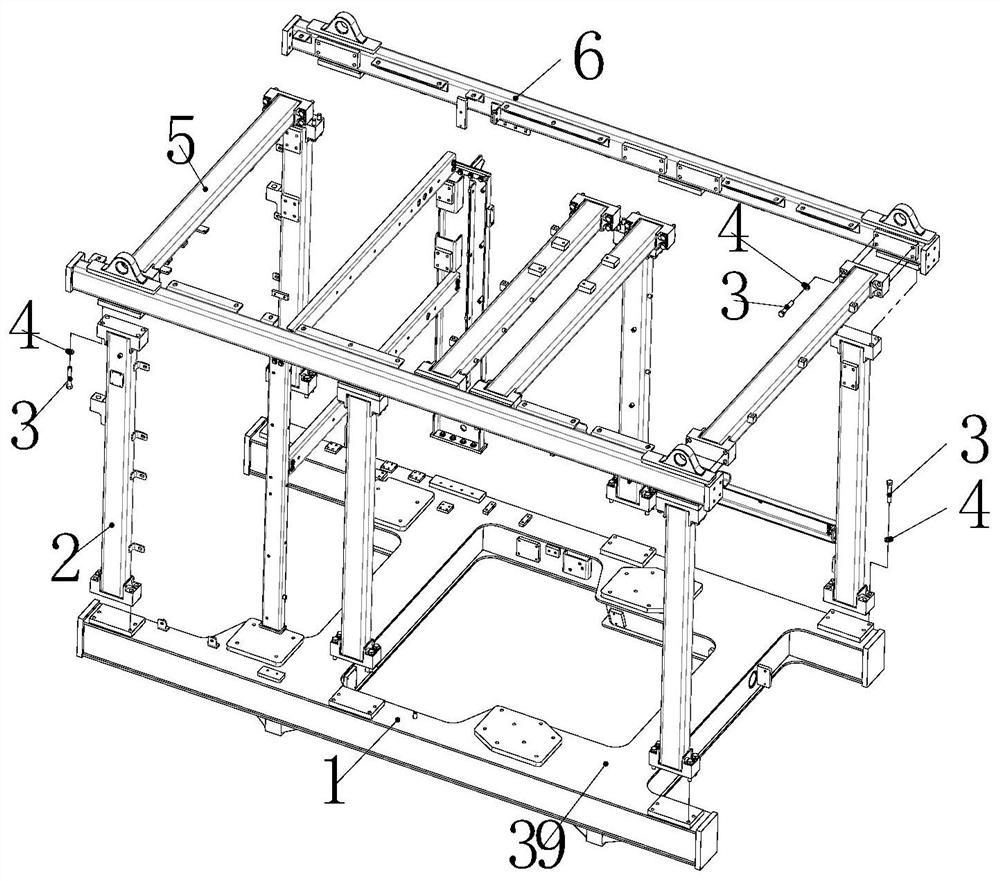

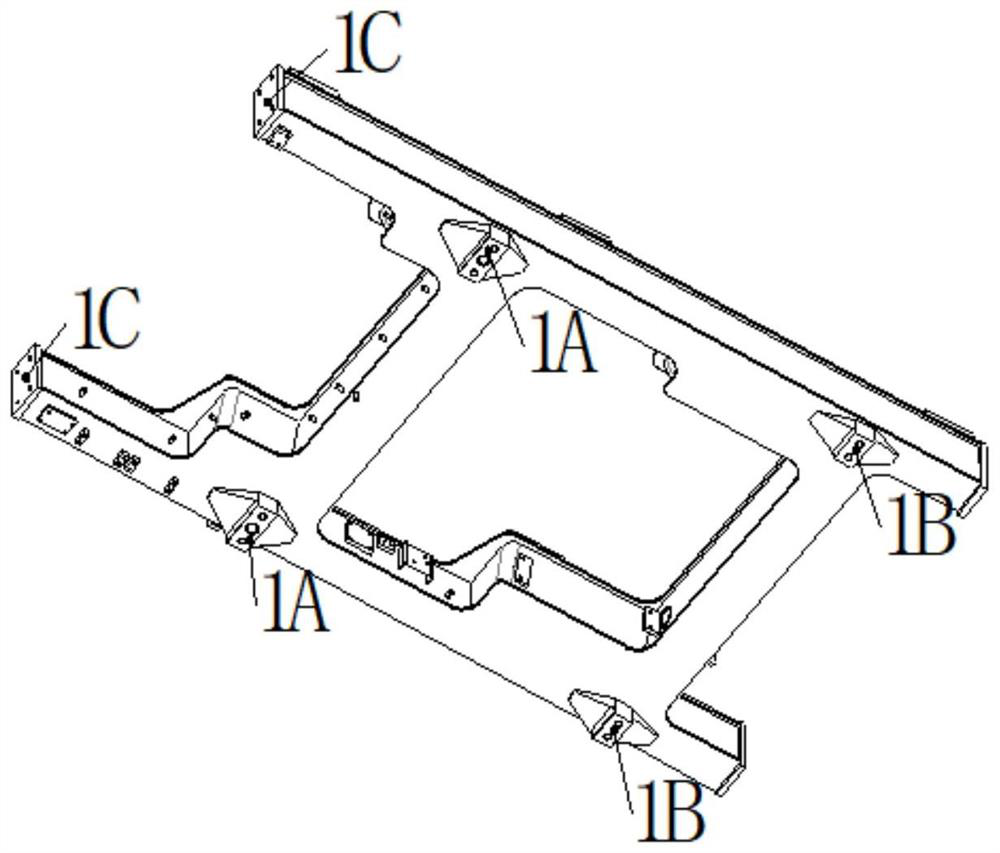

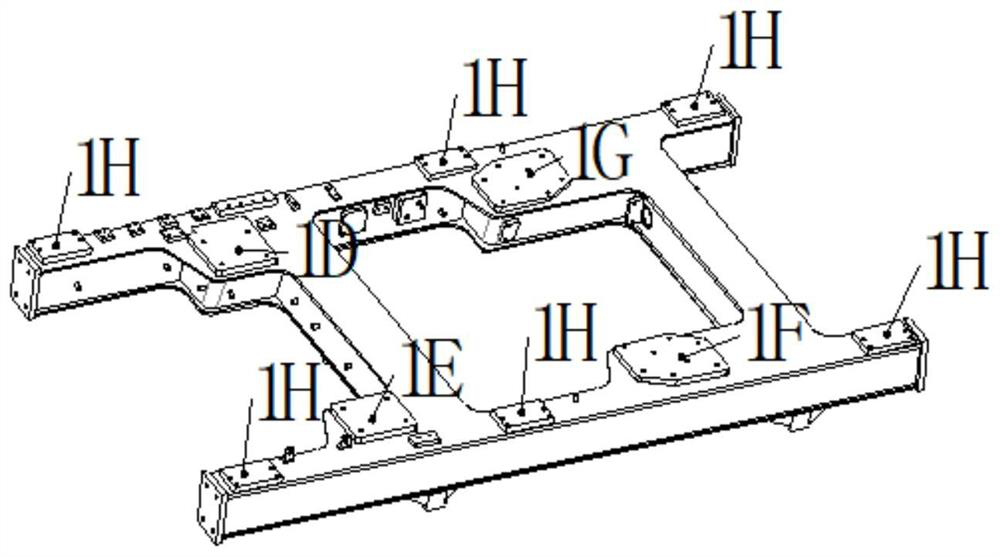

[0029] Such as Figure 1-12 As shown, a super-large-tonnage hydraulic excavator integrally assembled power cabin includes a power cabin 41, a power cabin frame 39 is arranged on the power cabin 41, and the power cabin frame 39 is detachably fixed on the rotary platform 40. The power cabin frame 39 It is assembled from the base of the power cabin 1, six columns 2, four short beams 5 and two long beams 6, and the connected columns 2, short beams 5 and long beams 6 are respectively connected by first bolts 3 It is connected with the first gasket 4 and then fixed on the power cabin base 1 as a whole to form an integrally assembled power cabin frame 39. When making, first assemble small pieces of each column 2, short beam 5 and long beam 6. Spot, welding, vibration aging after welding, release welding stress, prevent welding deformation after machining, and finally perform post...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com