Automatic efficient stirring device for cable material

A technology of mixing device and cable material, which is applied to mixers with rotary mixing devices, mixer accessories, transportation and packaging, etc., can solve the problems of heavy movement, inconvenience, and inability to pour the mixer, so as to improve work efficiency and improve mixing. quality, vibration reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

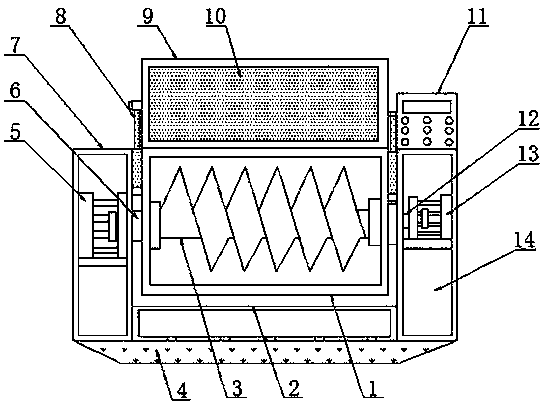

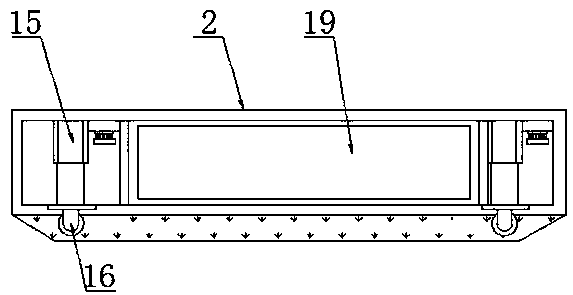

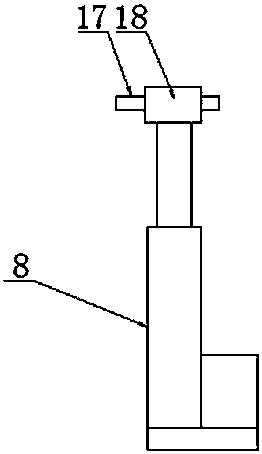

[0022] Example: such as Figure 1-3 As shown, the present invention provides a technical solution, an automatic high-efficiency stirring device for cable materials, including a mixing drum 1, a stirring shaft 3 is arranged inside the mixing drum 1, and a first drive is arranged on one side of the mixing drum 1 Box 7, the other side of the mixing drum 1 is provided with a second drive box 14, and the upper end of the mixing drum 1 is provided with a cover plate 9, and the lower end of the mixing drum 1 is provided with a bottom plate 2, and the inside of the bottom plate 2 is provided with a material temporary storage bucket 19, and the inside of the bottom plate 2 is provided with a second electric telescopic rod 15 at a position close to the side of the material temporary storage bucket 19, the lower end of the bottom plate 2 is provided with a rubber shock absorber 4, and the bottom end of the second electric telescopic rod 15 is provided with a mobile Wheel 16, the inside o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com