Sensing system for measuring soil properties in real time

A sensing system and characteristic technology, applied in the field of sensing systems, can solve the problems of low sensor resolution, adverse effects on crop production, and yield decline, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

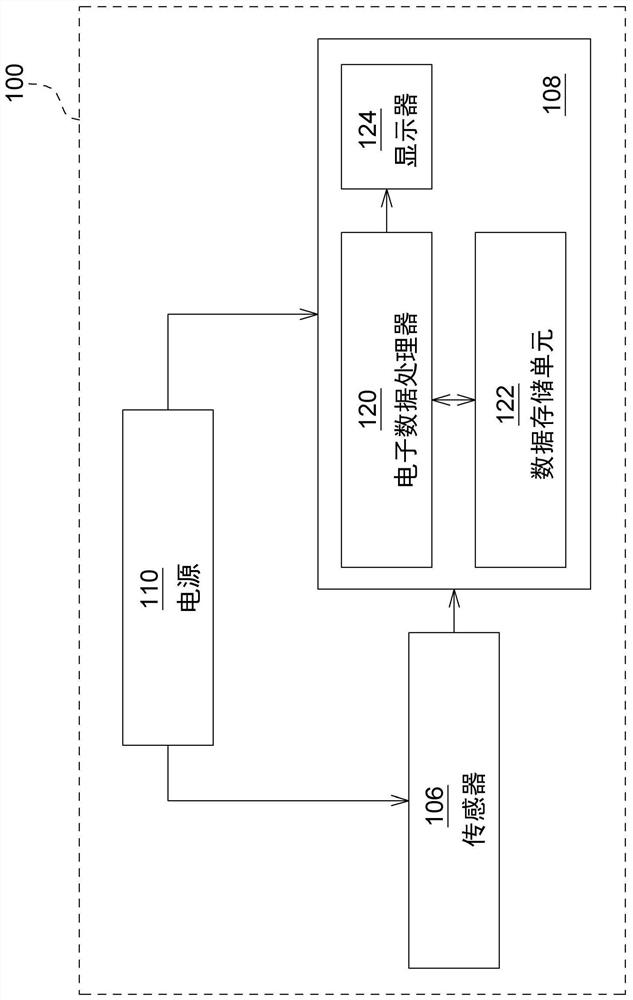

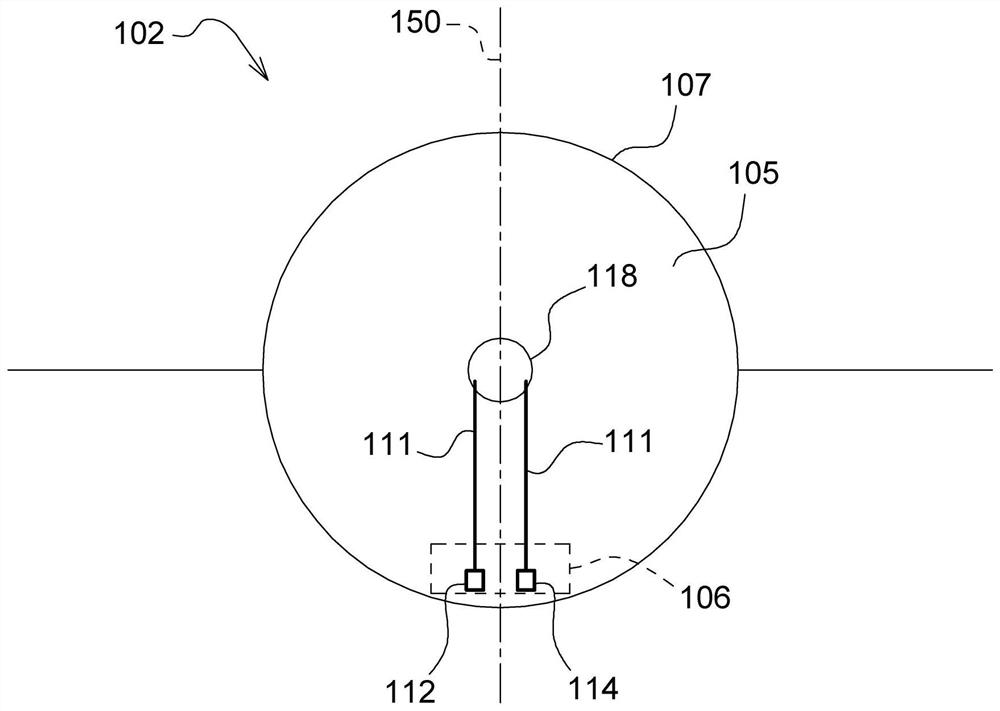

[0013] For clarity, this disclosure will be described as applied to a planter unit. It should be noted, however, that the present disclosure may also find application in various planting and / or soil preparation applications including, but not limited to, tilling, seeding, and the like. refer to Figure 1 to Figure 2B , shows a sensing system 100 for determining soil properties in real time, according to an embodiment. In an embodiment, sensing system 100 may include at least one sensor 106 disposed on support structure 102 (at Figure 2A middle) and is operatively coupled to the measurement unit 108. The support structure 102 may be adapted to be coupled to an agricultural implement (such as Figure 4A The planter unit 400 in ) and is arranged so that as the implement moves in the field, the support structure 102 rotationally engages or penetrates the surrounding soil. In some embodiments, support structure 102 may comprise a disc or another wheel-like structure (see, eg, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com