Track vertical reciprocating loading simulation experiment device

A technology that simulates experimental devices and loading devices, and is used in the testing of measuring devices, instruments, and mechanical components to reduce friction and experimental errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

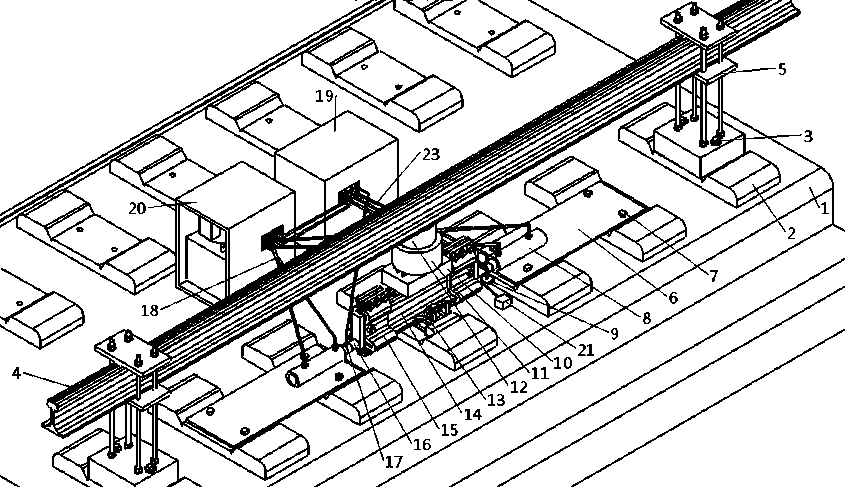

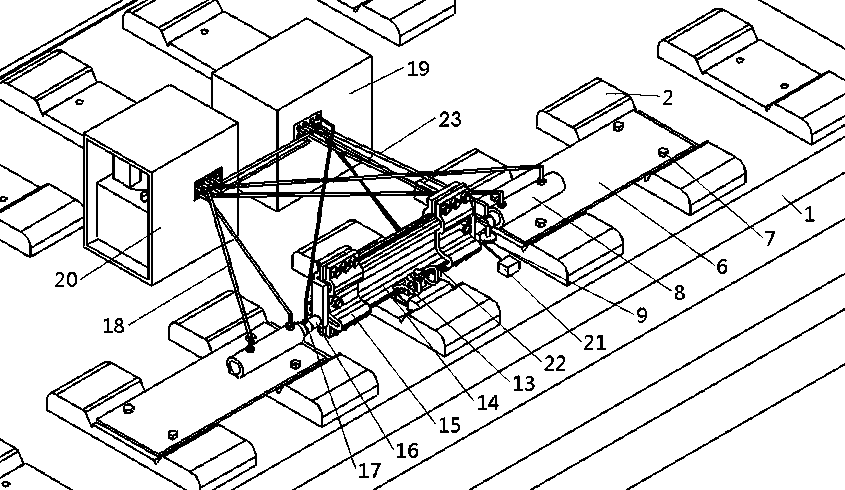

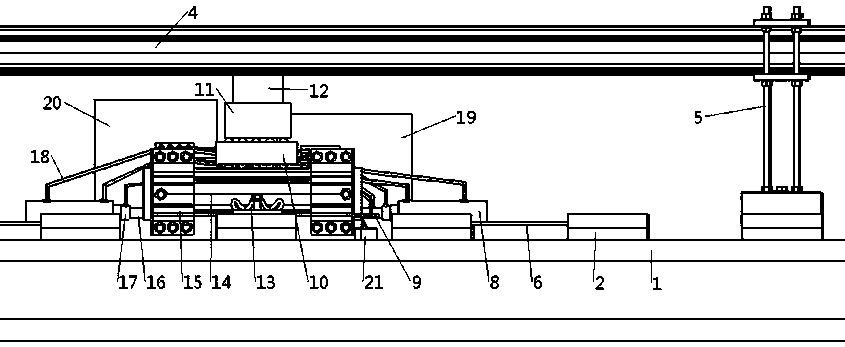

[0046] A rail longitudinal reciprocating loading simulation experiment device is characterized in that it includes a force applying assembly for applying a longitudinal reciprocating force to a rail on the rail, a vertical load loading device for providing vertical load conditions, and a A displacement measuring assembly for measuring the longitudinal displacement of the rail and the backing plate of the fastener; the object of the experimental device is the rail 14 buckled on the sleeper 2 by using the fastener 13;

[0047] The force application assembly has two sets of identical devices arranged on both sides of the rail 4, including a hydraulic jack 8 installed on the sleeper 2; 16 Connect the tension sensor 17 with the clamp 15, the clamp 15 is installed at both ends of the rail 14; the tension sensor 17 is connected with the electro-hydraulic servo control system 19 through a wire 23, and the hydraulic jack 8 is connected with the environment control box 20 through the oil p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com