Method for carrying out tunnel rapid deformation measurement by close-range photography

A technology of close-range photography and tunneling, which is applied in the direction of measuring devices, optical devices, instruments, etc., and can solve problems such as difficulty in meeting exposure time, insufficient natural light space, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086] The present invention will be further described below in conjunction with accompanying drawing:

[0087] The present invention The present invention realizes above-mentioned purpose through following technical scheme:

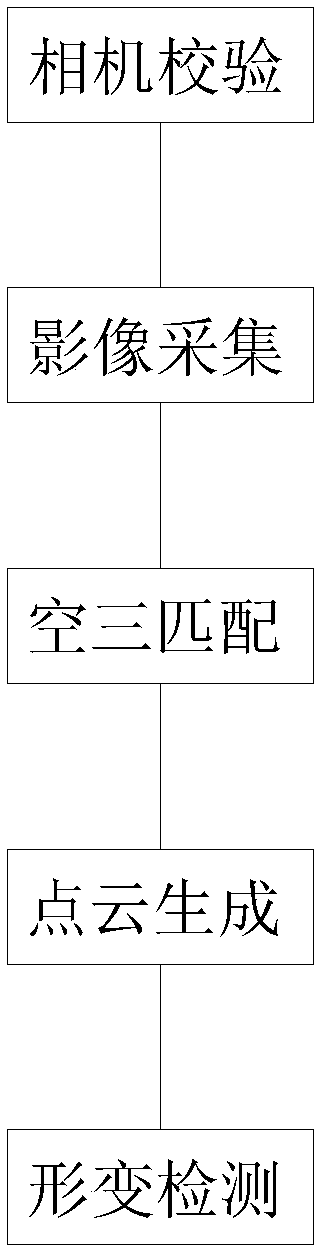

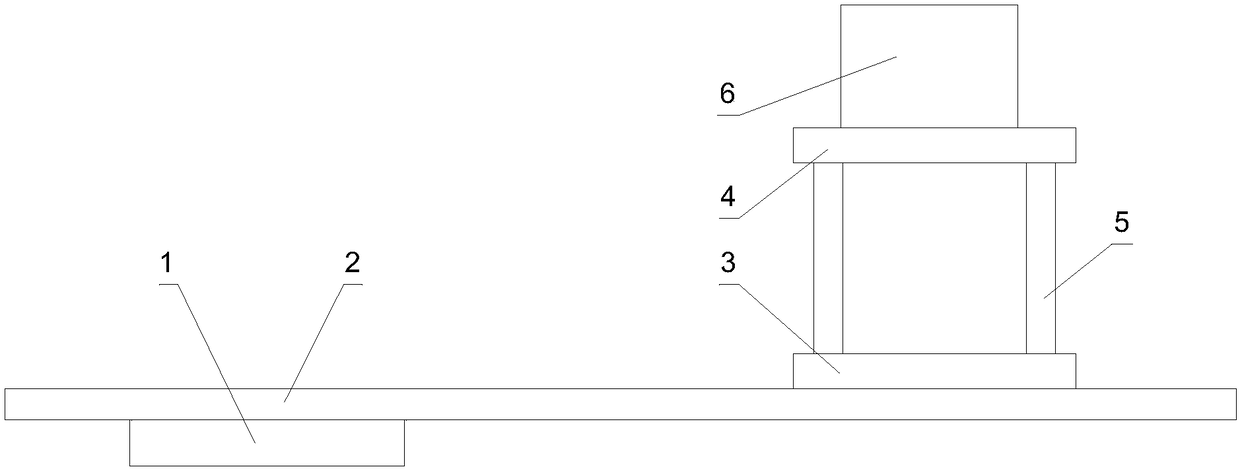

[0088] Such as figure 1 As shown, a method for rapid deformation measurement of tunnels using close-range photography, including camera calibration, image acquisition, spatial three-matching, point cloud generation and deformation detection;

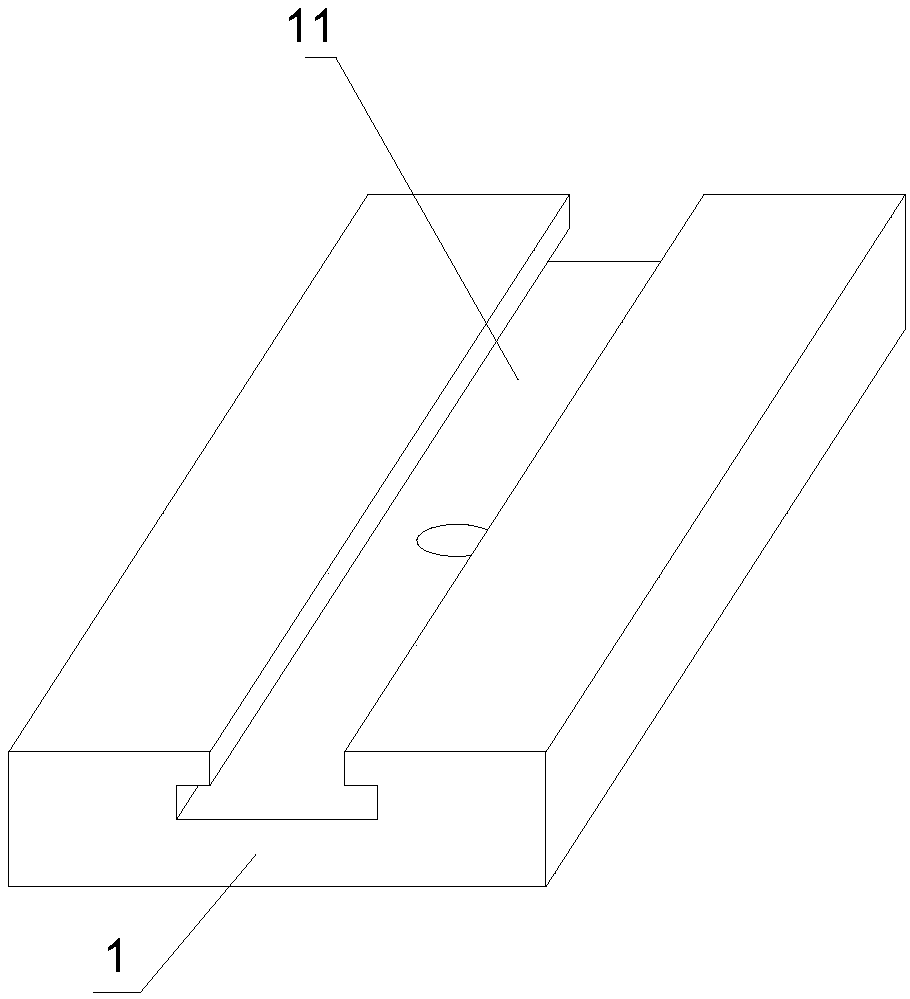

[0089] S1. Camera calibration, by establishing the corresponding relationship between known object points and image points, calculate the internal orientation elements of the imaging system;

[0090] Specifically include the following steps:

[0091] A1. Fix the camera to shoot the calibration plate, obtain the image of the calibration plate, and obtain the equation according to the imaging model of the collinear equation of the camera:

[0092]

[0093] The eigenvector corresponding to its minimum eigenvalue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com