Multi sprocket arrangement with weld connection

A welding connection and sprocket technology, applied in welding equipment, hubs, manufacturing tools, etc., can solve the problem of insufficient space for press-fit connection, and achieve the effect of economical manufacturing and integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

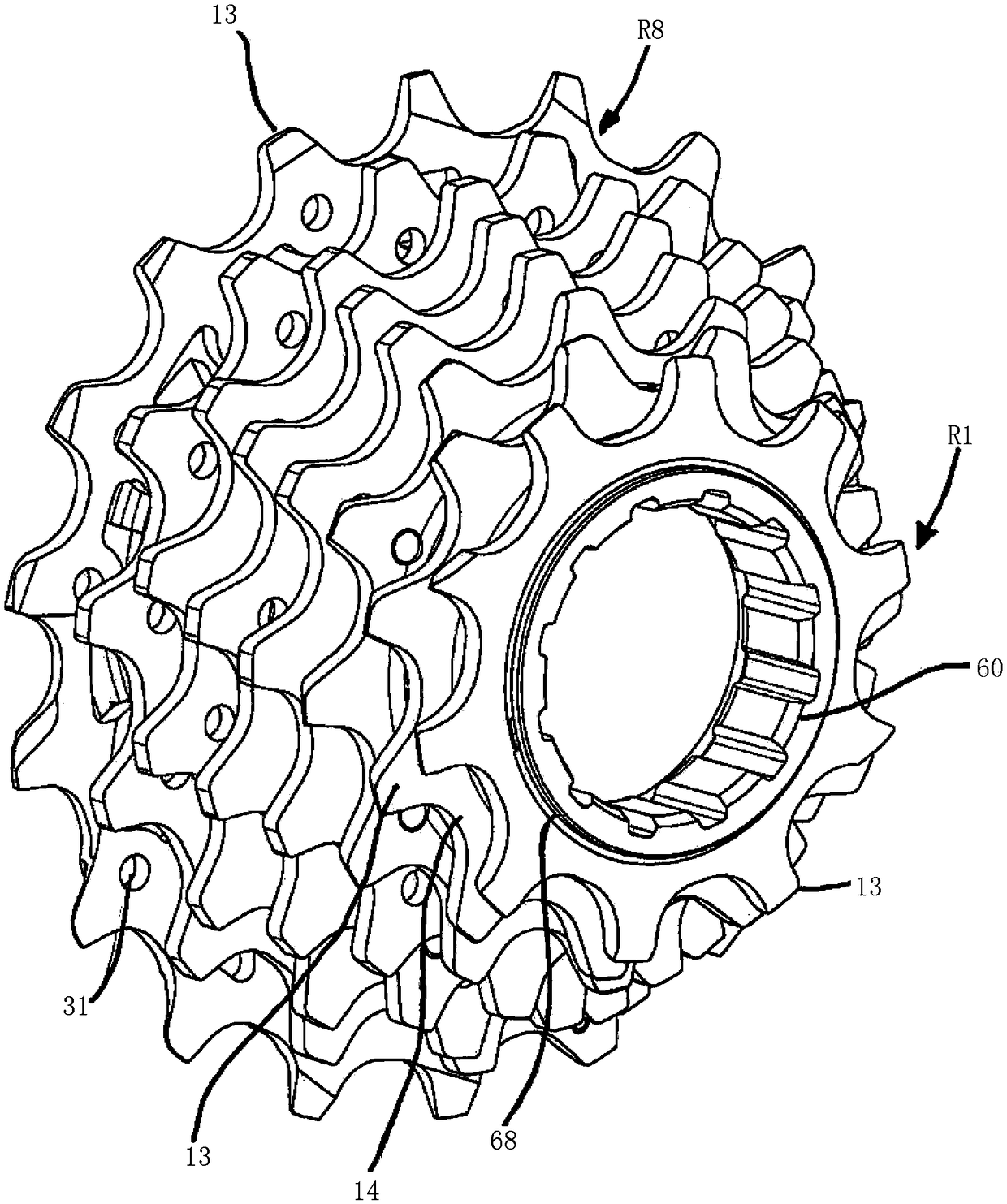

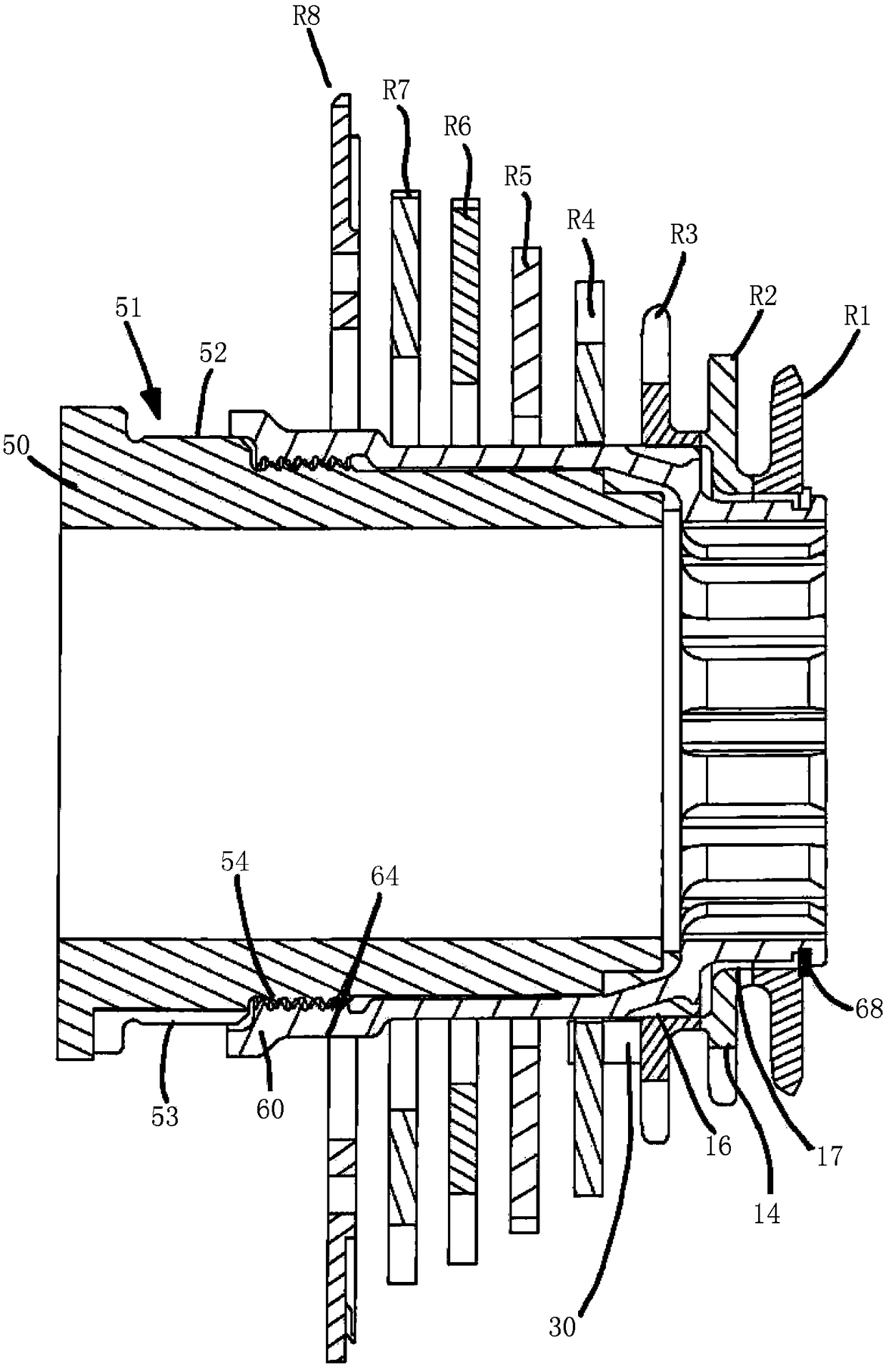

[0068] As mentioned below, the directions "front" and "rear" denote the front and rear sides of the sprocket, respectively. The front side of the sprocket points to the next smaller sprocket. The rear side of the sprocket points to the next larger sprocket. The term "axial" relates to the rear wheel axis or the axis of rotation of the multi-sprocket arrangement. The teeth are arranged radially on the outer side of the sprocket.

[0069] The outer diameter of the sprocket is the radially outer end of the sprocket, and the inner diameter is the radially inner end thereof. The figures are purely by way of example and only show some of the sprockets of the multi-sprocket structure for the sake of clarity.

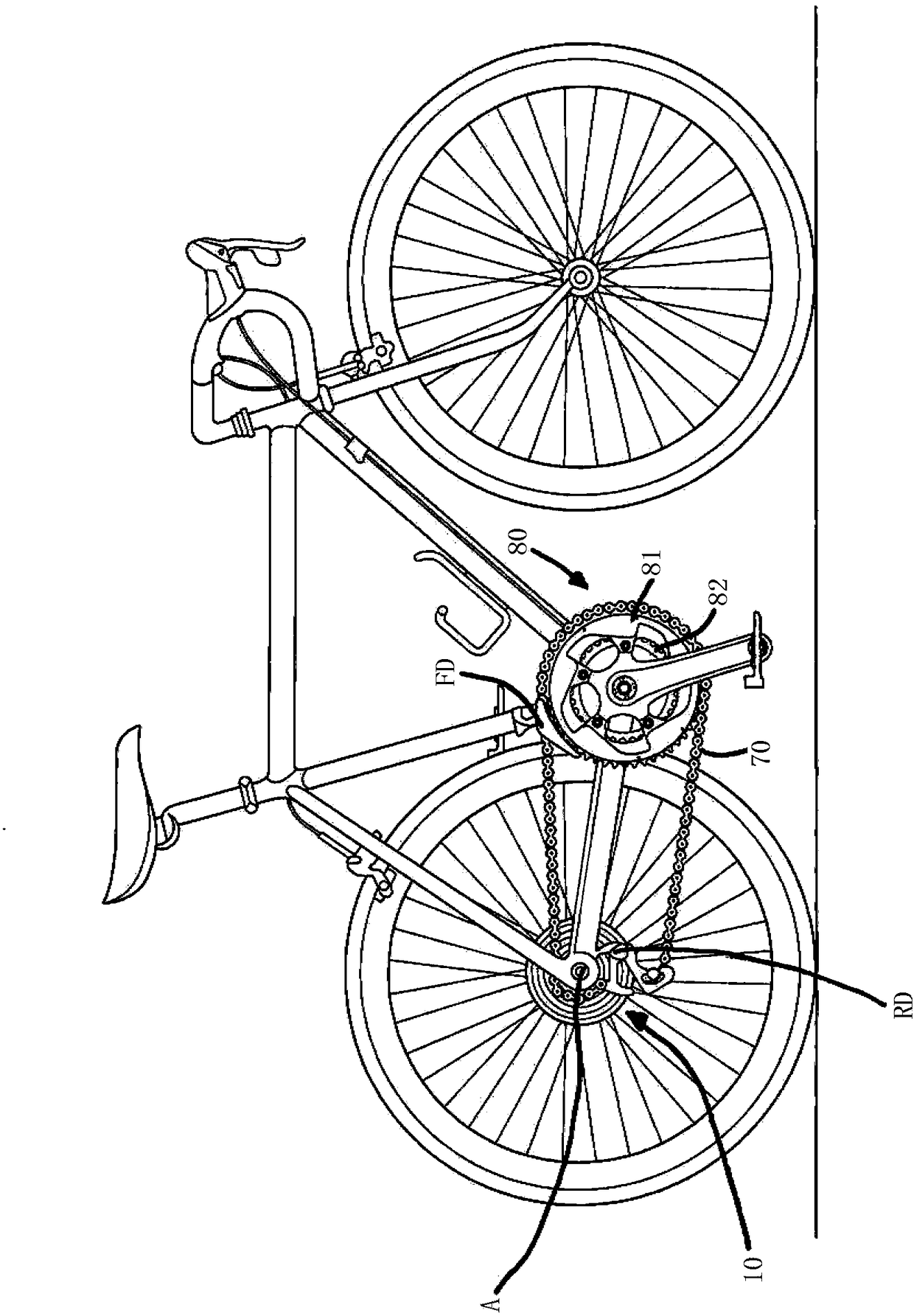

[0070] figure 1 A bicycle comprising a multiple sprocket arrangement 10 according to the invention and a bicycle drive device according to the invention is shown. The bicycle driving device consists of a wheel structure 80 with a small wheel 82 and a large wheel 81 , a mul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com