Pipe cutting equipment based on electromagnetic driving principle

An electromagnetic drive, pipe cutting technology, applied in the field of pipes, can solve the problems of uneven section surface, inability to cut pipes, waste of time and materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

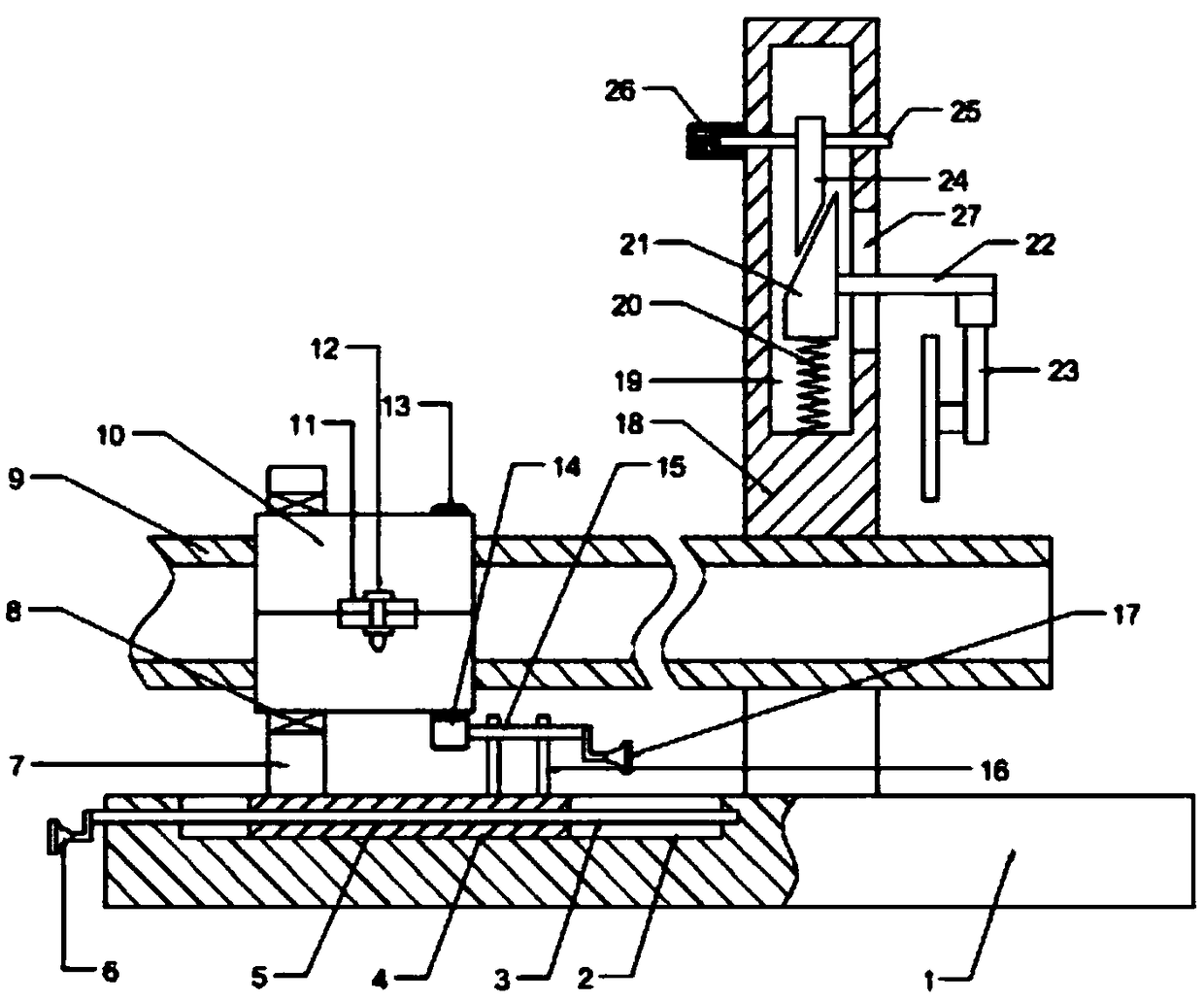

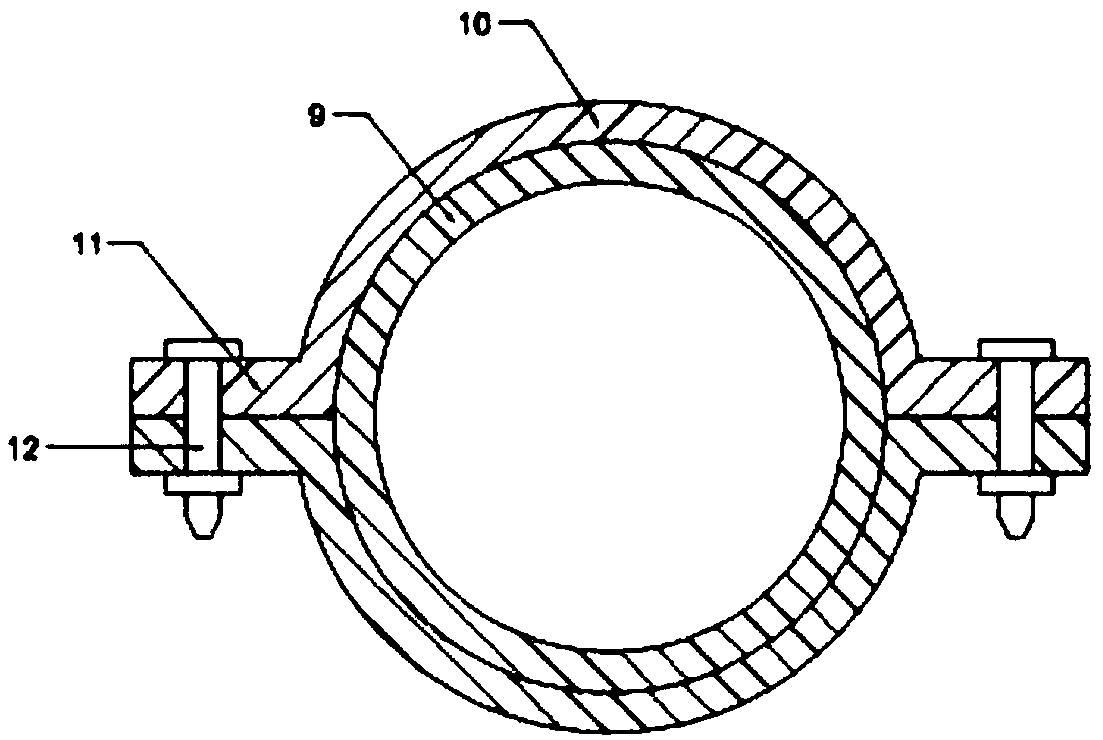

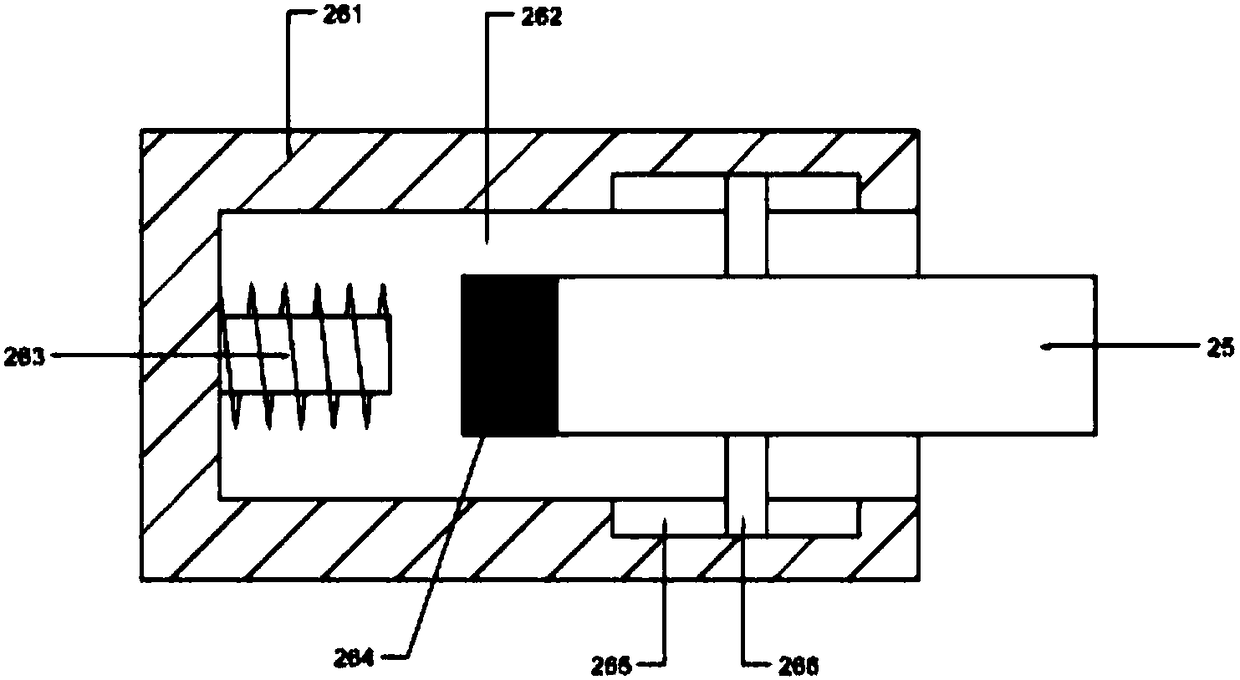

[0022] see Figure 1-Figure 3 , in this embodiment, a pipe cutting device based on the principle of electromagnetic drive, including a base 1, a groove 2 is opened on the base 1, a moving plate 4 is arranged in the groove 2, and a horizontal threaded passage is opened on the moving plate 4. Hole 5, horizontal threaded through hole 5 is internally threaded with a threaded rod 3, the left end of the threaded rod 3 extends to the left side of the base 1, the left end of the threaded rod 3 is fixedly connected with a first handle 6, the upper side of the moving plate 4 is fixed Connected with a first support plate 7, the first support plate 7 is provided with a ball bearing 8, and the ball bearing 8 is provided with a pipe clamping device. After a cutting is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com