Aluminum profile metal hardness detection platform

A technology for testing platforms and aluminum profiles, applied in the direction of testing material hardness, measuring devices, analyzing materials, etc., can solve the problems of wasting time, inconsistent results, inconsistent sharpness of testing tools, etc., to achieve good testing results, labor saving, and high efficiency. The effect of automated detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

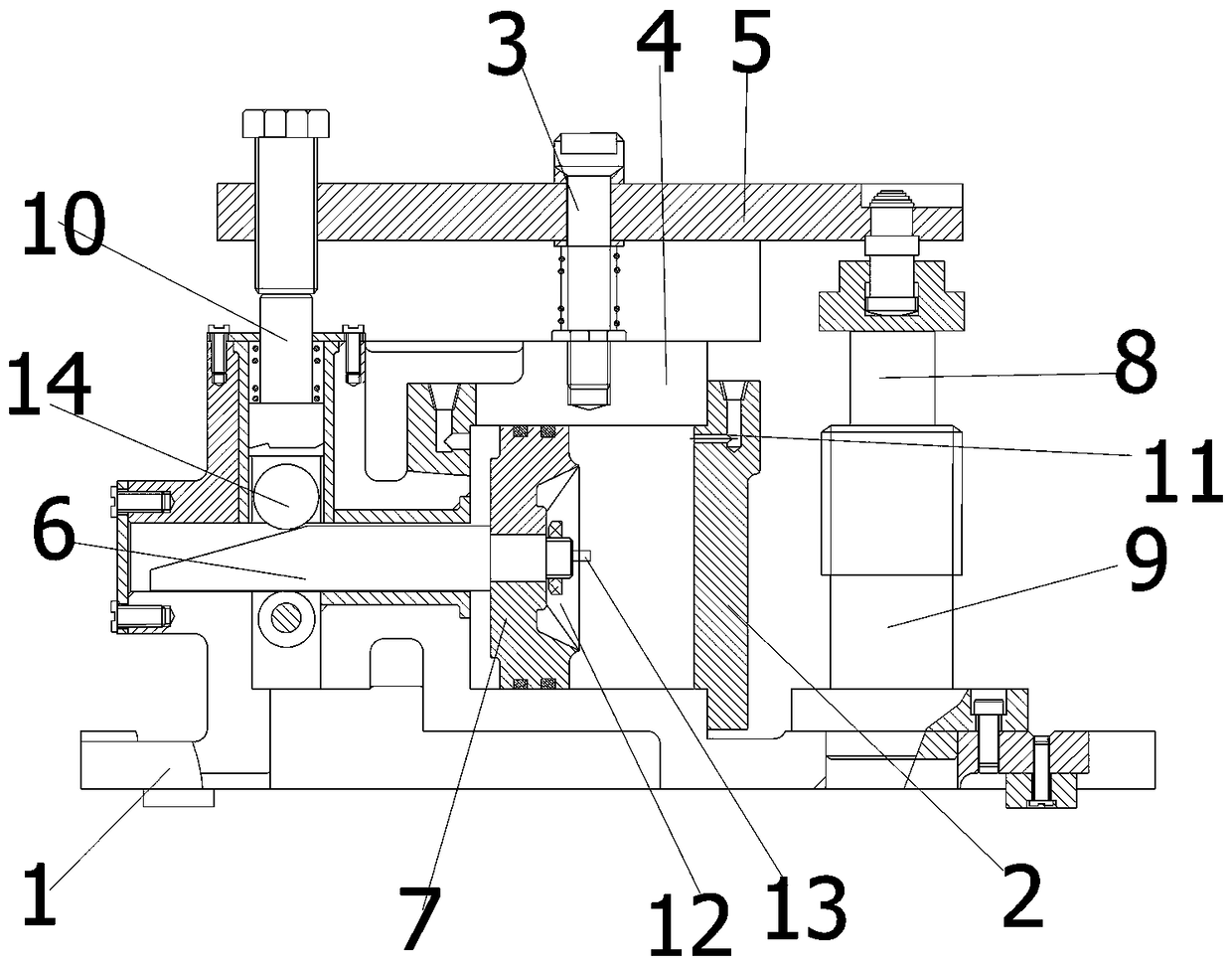

[0014] In order to more clearly illustrate the technical solutions in the embodiments of the present invention or the prior art, the following will briefly introduce the drawings that need to be used in the description of the embodiments or the prior art. Obviously, the accompanying drawings in the following description are only These are some embodiments of the present invention. For those skilled in the art, other drawings can also be obtained according to these drawings without any creative effort.

[0015] see as figure 1 As shown, the present embodiment adopts the following technical scheme: it comprises a base 1, a frame 2, a vertical push rod 3, a pressing plate 4, a transmission shaft 5, a horizontal push rod 6, a friction disc 7 and a constant force meter 8; 1 The upper part is screwed to fix the frame 2; the upper part of the frame 2 is designed with a transmission shaft 5; the front end of the transmission shaft 5 is vertically connected to the constant force meter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com