Anti-seismic threaded pipeline connecting part

A technology of pipe connectors and connectors, which is applied in the direction of pipes/pipe joints/fittings, adjustable connections, passing elements, etc., can solve problems such as deformation, damage, and falling off of pipeline nodes, and achieve improved lateral shear stiffness and processing Convenient and easy to assemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

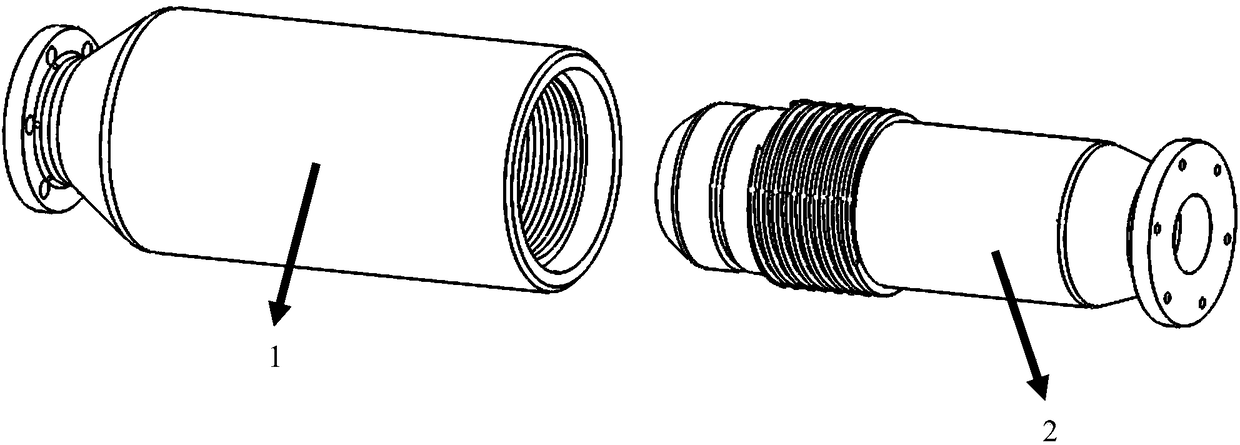

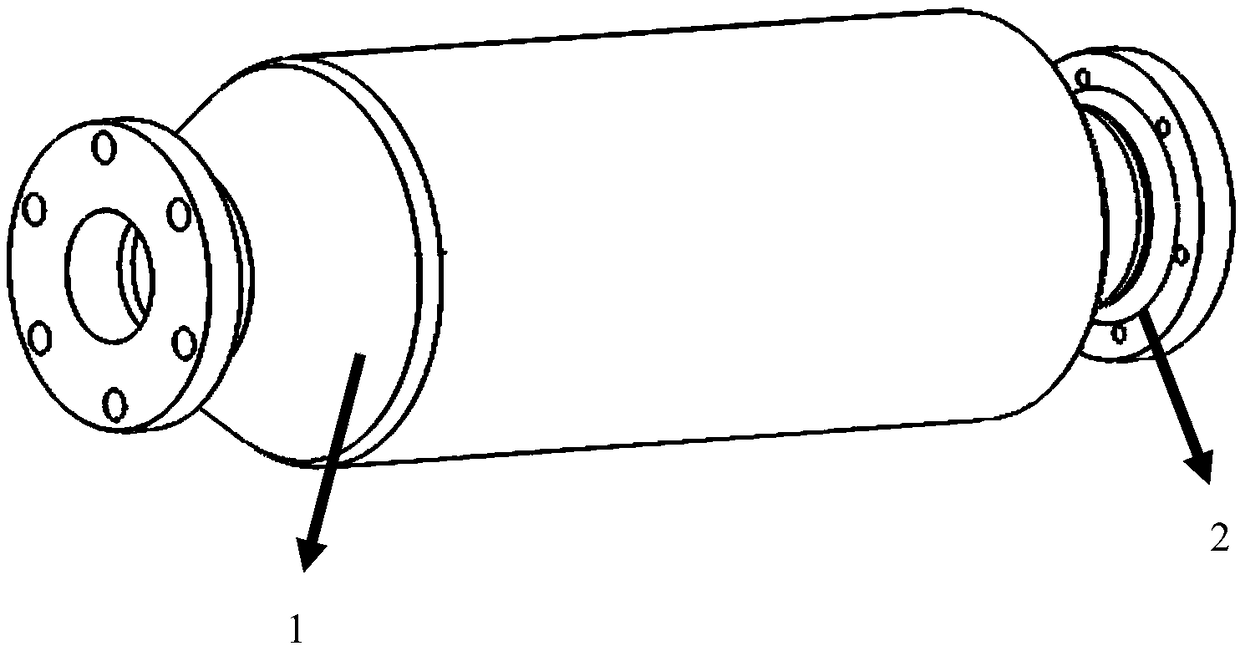

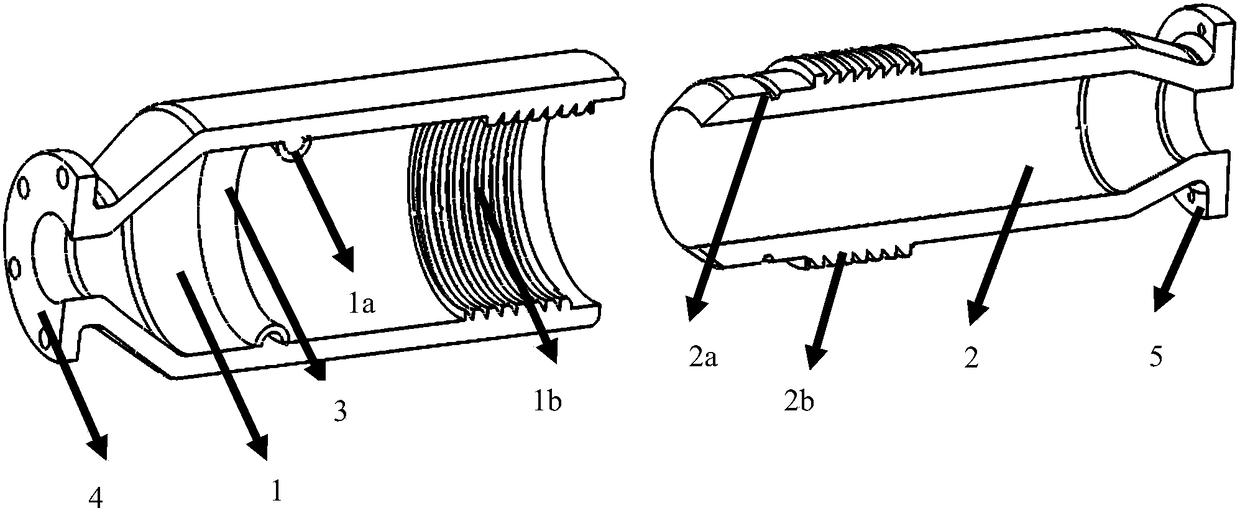

[0041] The present invention is described in detail below in conjunction with the accompanying drawings: the anti-seismic threaded pipe connector includes a connector socket (1), a connector socket (2), a water-stop rubber ring (3), a socket flange (4) and a socket method Orchid plate (5).

[0042] Install the water-stop rubber ring (3) at the position of the annular protrusion (1a) of the connector socket (1) first;

[0043] After installing the water-stop rubber ring (3), insert the connector socket (2) into the socket (1). Before inserting, apply a layer of lubricant to the water-stop rubber ring to facilitate installation.

[0044]After installing the water-stop rubber ring (3) to the position of the annular protrusion (1a) of the socket, insert it into the pipe socket (2), when the external thread (2b) of the socket contacts the internal thread (1b) of the socket, start screw in. After the screw-in is completed, continue to insert until the ring groove (2a) of the socke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com