Method for hoisting heavy large covers for towers

A hoisting method and a large cover technology, which are applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems that affect the maintenance of the synthetic tower, the problem of large cover hoisting, and the corrosion of the peg rings, etc., to achieve simple production and low input cost , does not affect the effect of the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] A method for hoisting rings of a heavy-duty tower cover of the present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments:

[0038] A ring hoisting method for a heavy-duty large cover of a tower, comprising the following steps:

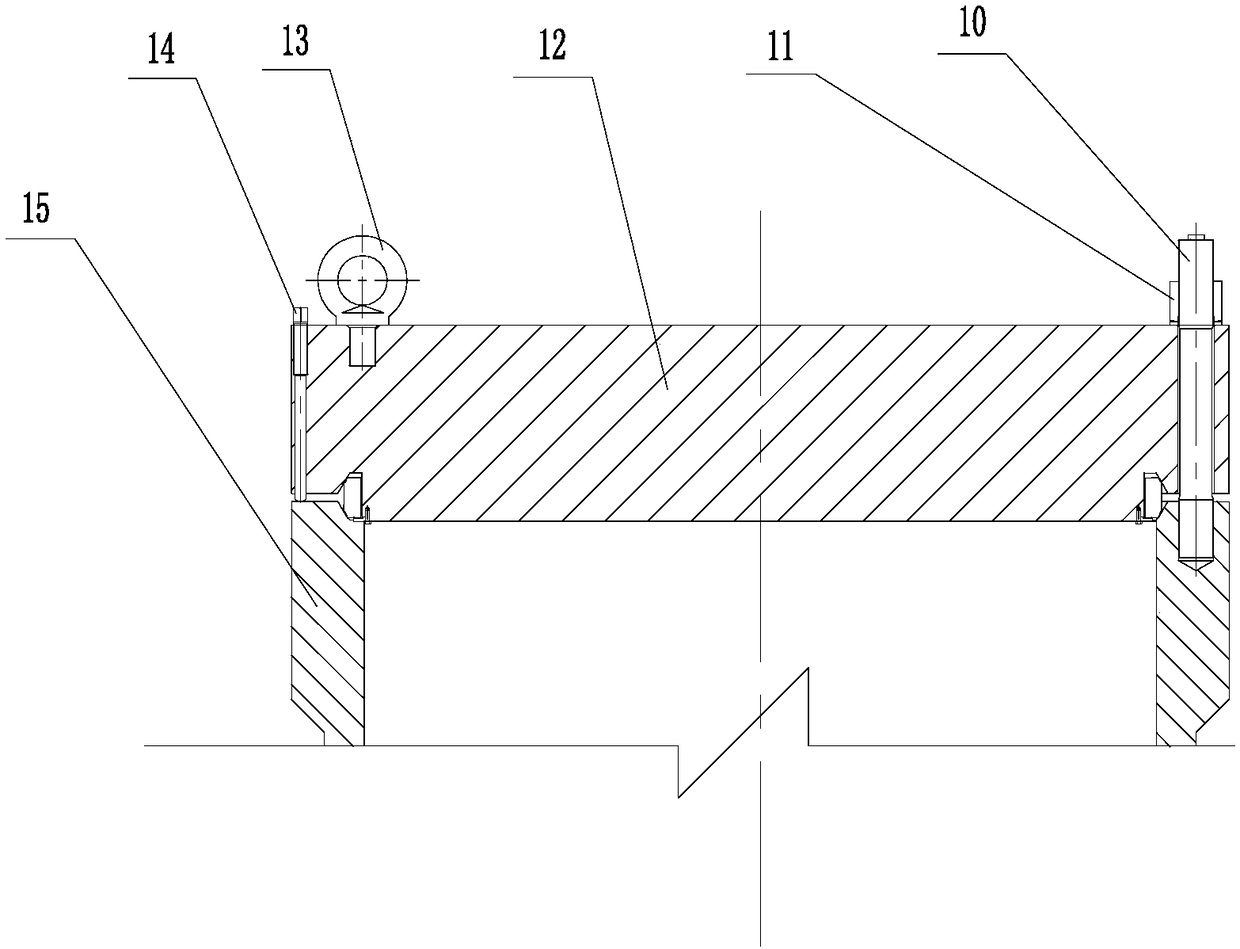

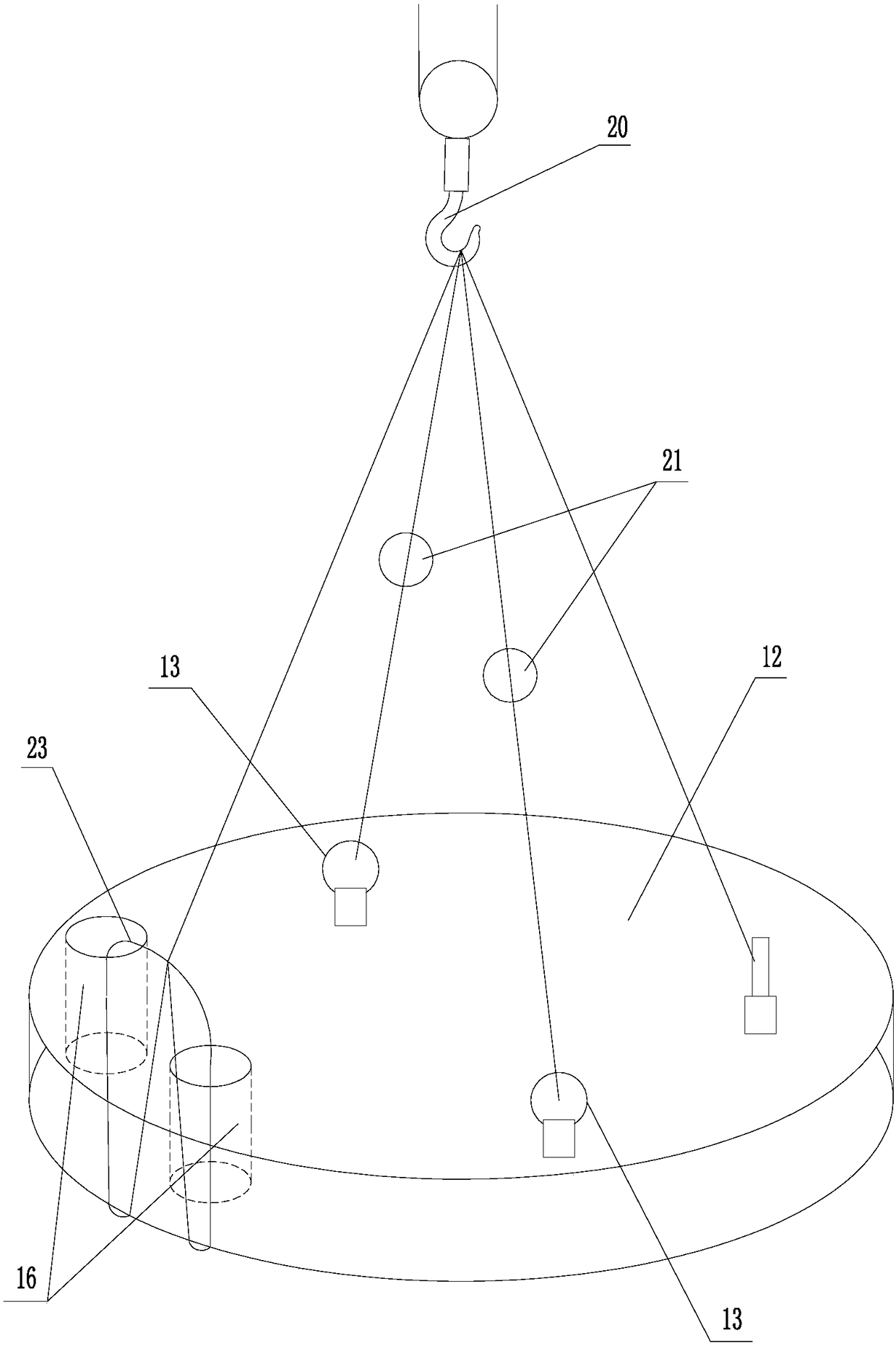

[0039] 1) see figure 1 , remove all M105 nuts 11 on the large cover 12;

[0040] 2) see Figure 4 , use a 12mm thick steel plate to make 4 pieces of 150×100mm top wire U-shaped gaskets Ⅰ241, and then use a 1mm thick stainless steel plate to make 56 pieces of 150×100mm top wire U-shaped gaskets Ⅱ242:

[0041] 3) see figure 1 and 2 , and slowly rotate the four jacking wires 14 evenly installed on the 12 circles of the large cover to lift the large cover 12 upward;

[0042] 4) Divide 4 pieces of jackscrew U-shaped spacers Ⅰ 241 into four groups, one for each group; divide 56 pieces of top-screw U-shaped spacers Ⅱ 242 into four groups, with 14 pieces in each group;

[0043] 5) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com