Wax-polishing machine with micro-vibration mode

A technology of micro-vibration and mode, which is applied in vehicle maintenance, vehicle maintenance/repair, transportation and packaging, etc. It can solve the problems of poor waxing effect and achieve the effect of solving poor waxing effect and difficult operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

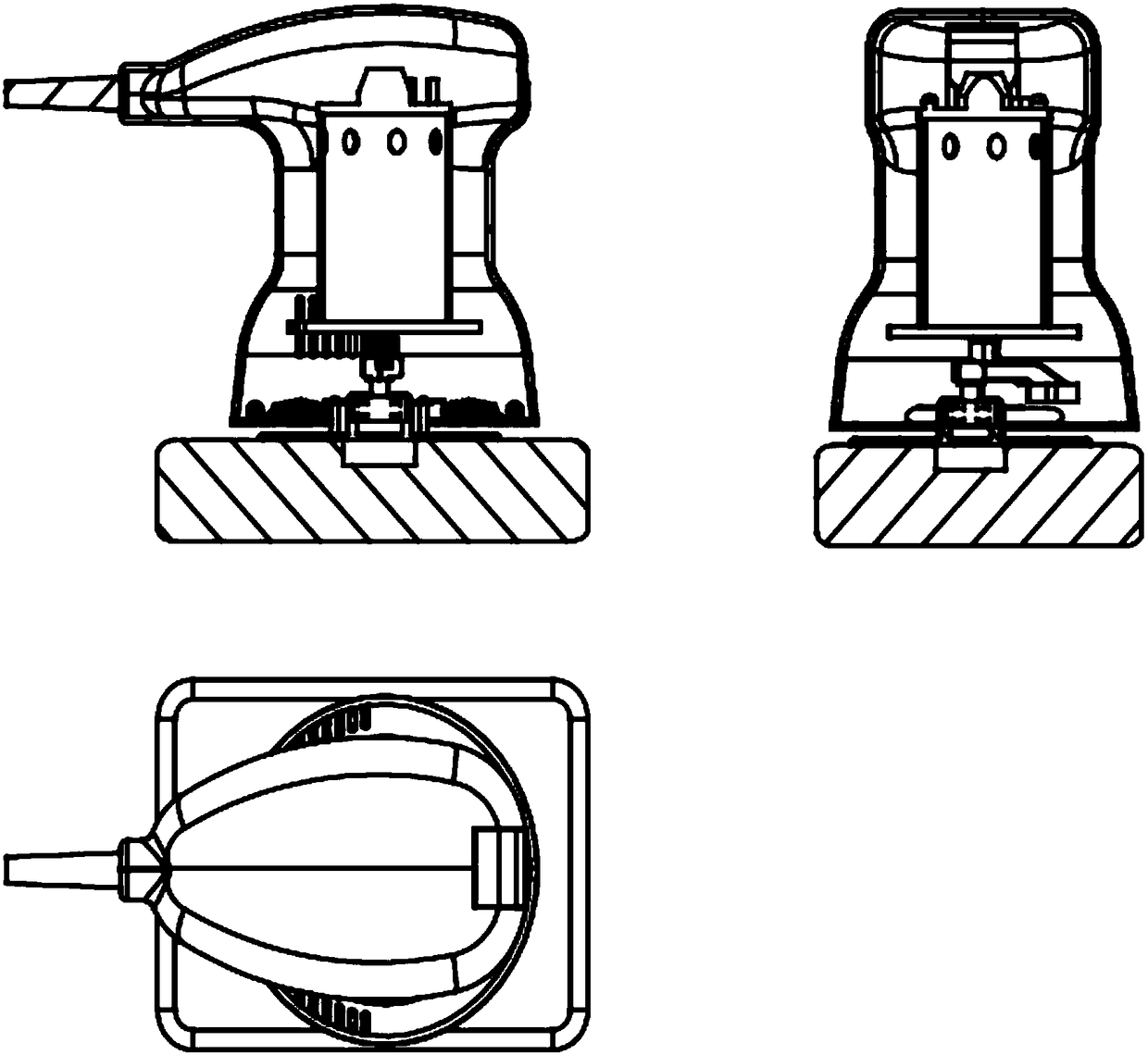

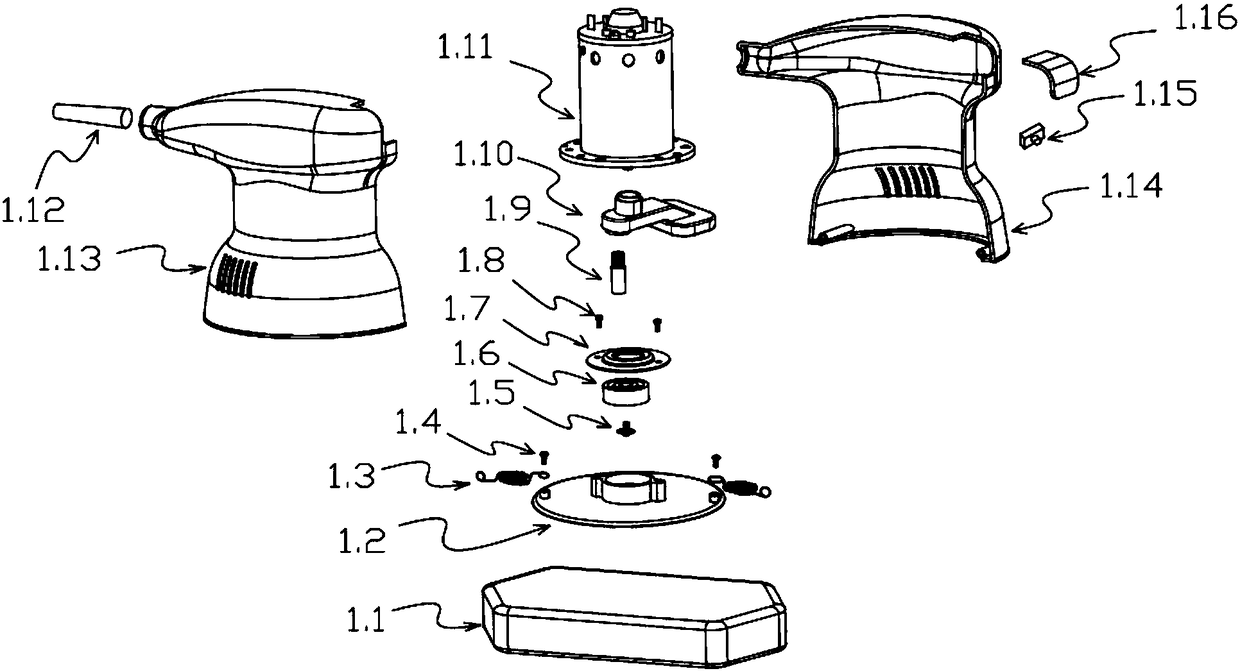

[0031] Example 1 (combined figure 1 and figure 2 describe):

[0032] For the single-head waxing machine, the output shaft of the motor 1.11 is fixed as a whole with the threaded hole at the upper end of the eccentric block 1.10 by means of threaded connection, so the eccentric block 1.10 and the motor 1.11 together with the motor 1.11 to make a circular motion along the axis of the main shaft of the motor. On the other hand, the threaded hole at the lower part of the eccentric block and the stub shaft 1.9 on the vibrating plate 1.2 are fixed as a whole by means of threaded connection; while the stub shaft 1.9 and the inner ring of the bearing 1.6 are fixed as a whole by the set screw 1.5, so that The eccentric block 1.10, the stub shaft 1.9 and the bearing 1.6 are regarded as a rigid assembly A with the motor, and this assembly A rotates at high speed with the rotation of the main shaft of the motor.

[0033] Waxing disc 1.1 is directly connected with vibrating disc 1.2 by ...

Embodiment 2

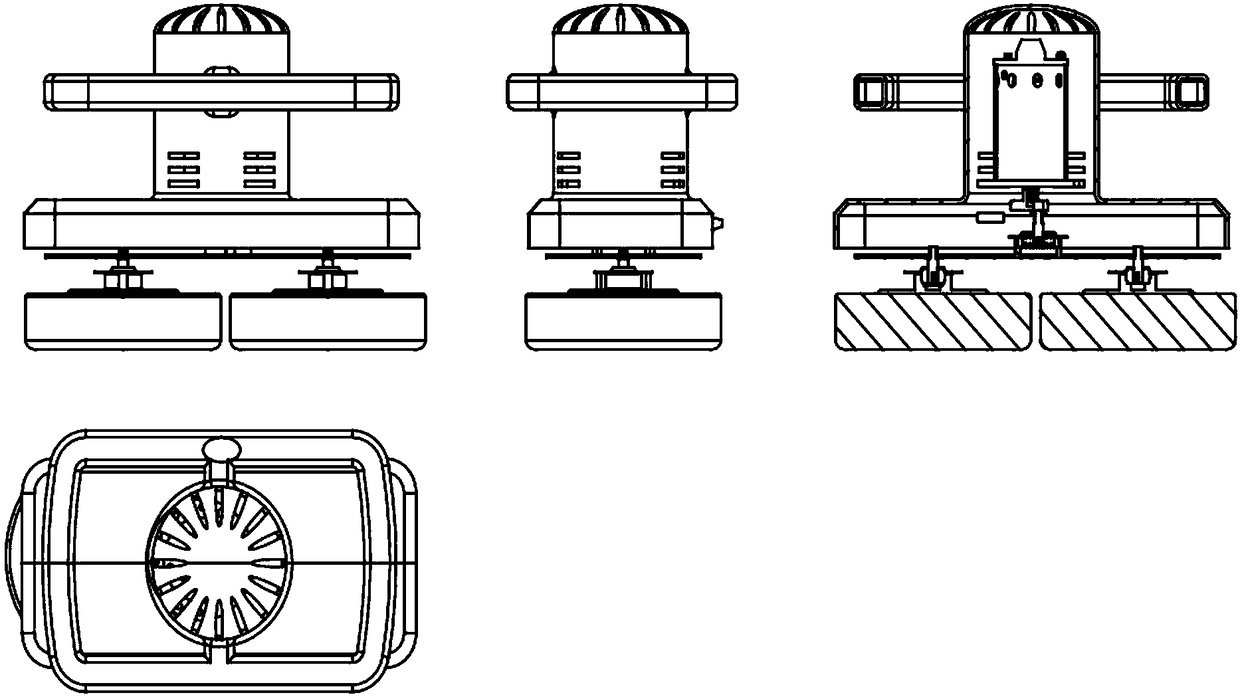

[0037] Example 2 (combined image 3 and Figure 4 describe):

[0038] The sub-waxing disc 2.17 of the multi-head waxing machine (referring to two or more waxing discs) is directly connected to the vibrating disc 2.8 by means of pasting, or through the sub-waxing disc group 2.11~2.16 and vibration. The discs 2.8 are connected by fasteners. The structural design of directly pasting the multi-head waxing disc to the vibrating disc is the same as that of the single-head waxing machine, and will not be repeated here. In the following, only the focus of the sub-waxed disk structure mode will be described in detail.

[0039] The output shaft of the DC motor 2.2 on the multi-head waxing machine is fixed as a whole with the threaded hole at the upper end of the eccentric block 2.3 by means of threaded connection, so the eccentric block 2.3 is together with the motor 2.2. On the other hand, the threaded hole at the lower part of the eccentric block 2.3 and the stub shaft 2.4 on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com