Automatic nut fastening machine interacting with robot and method for loading or unloading nuts thereon

A nut screwing machine and robot technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems that cannot satisfy the full-line automatic operation of resale workstations, so as to ensure the consistency of test bodies, improve stability, and improve work efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

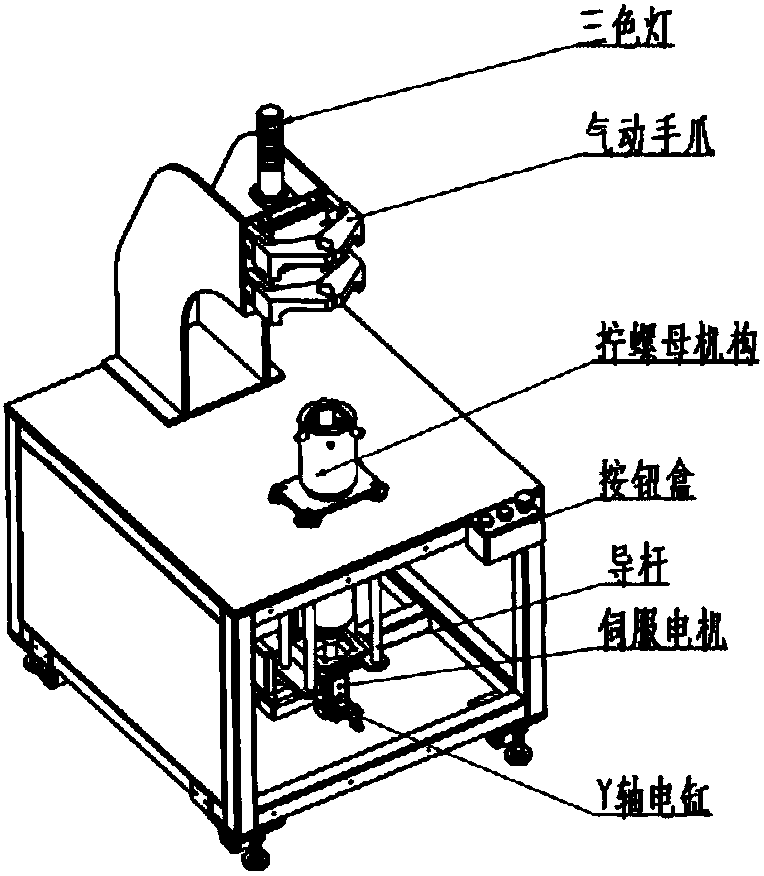

[0060] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0061] The detailed features and advantages of the present invention are described in detail below in the specific embodiments, the content of which is sufficient to enable any person skilled in the art to understand the technical content of the present invention and implement it accordingly, and according to the specification, claims and drawings disclosed in this specification , those skilled in the art can easily understand the related objects and advantages of the present invention.

[0062] Aiming at the shortcomings of the existing manual nut tightening methods, the present invention proposes a new method for tightening installation nuts. This method can quickly and efficiently realize the automatic tightening of nuts for reselling workpieces, perform tensile tests, and realize full automation of workstations. Realize the interactive w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com