A kind of preparation method of plum powder

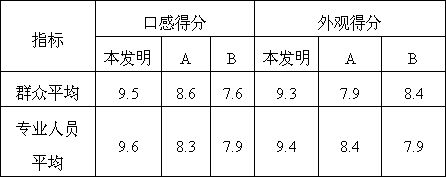

A technique for plum powder and green plum, which is applied in the field of preparation of plum powder, can solve problems such as hidden safety hazards and calculi, and achieve the effects of good tissue structure, rich taste and unique taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A kind of preparation method of plum powder, its processing production process is as follows:

[0024] (1) Greengage material selection: select the original greengage fruit produced in Puning City, Guangdong Province, and the original greengage fruit is required to be 7 mature.

[0025] (2) Pickling: Take 30% of the weight of the greengage with salt and pickle the greengage in the pickling pool, using a layer of greengage and layer of salt to pickle, and finally cover the surface of the pickled product with gauze, and put it in the gauze Stones are pressed on the net; during the pickling process, the liquid in the pickling pool is circulated every day from the second day to ensure the pickling effect of greengage in the pickling pool, and the pickling is 240 days.

[0026] (3) Preparation of dry and wet plums: take out the marinated greengages in step (2), and dry them in the sun until the water is 55% to prepare dry and wet plums.

[0027] (4) Aging: Put the dry and w...

Embodiment 2

[0034] A kind of preparation method of plum powder, its processing production process is as follows:

[0035] (1) Greengage material selection: select the original greengage fruit produced in Luhe County, Guangdong Province, and the original greengage fruit is required to be 7 mature.

[0036] (2) Pickling: Take 34% of the weight of greengage in salt to pickle the greengage in the pickling pool, pickle with a layer of greengage and layer of salt, and finally cover the surface of the pickled product with gauze, Stones are pressed on the net; during the pickling process, the liquid in the pickling pool is circulated every day from the second day to ensure the pickling effect of greengage in the pickling pool, and the pickling is 350 days.

[0037] (3) Preparation of dry and wet plums: take out the marinated greengages in step (2), and dry them in the sun until the moisture reaches 60% to prepare dry and wet plums.

[0038] (4) Aging: Put the dry and wet plums prepared in step (...

Embodiment 3

[0045] A kind of preparation method of plum powder, its processing production process is as follows:

[0046] (1) Greengage material selection: select the original greengage fruit produced in Puning City, Guangdong Province, and the original greengage fruit is required to be 7 mature.

[0047] (2) Pickling: Take 36% of the weight of greengage with salt and pickle the greengage in the pickling pool, using a layer of greengage and layer of salt to pickle, and finally cover the surface of the pickled product with gauze, Stones are pressed on the net; during the pickling process, the liquid in the pickling pool is circulated every day from the second day to ensure the pickling effect of greengage in the pickling pool, and the pickling is 540 days.

[0048] (3) Preparation of dry and wet plums: take out the marinated greengages in step (2), and dry them in the sun until the water is 65% to prepare dry and wet plums.

[0049](4) Aging: Put the dry and wet plums prepared in step (3)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com