Touch pressure sensor and touch pressure switch

A touch pressure, sensor technology, applied in the field of sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The core of the present invention is to provide a touch pressure sensor. In the prior art, the user only needs to touch or approach the surface of the capacitive touch sensor with a finger to activate the touch sensor, which can easily cause false triggering of the touch sensor, thereby reducing the safety.

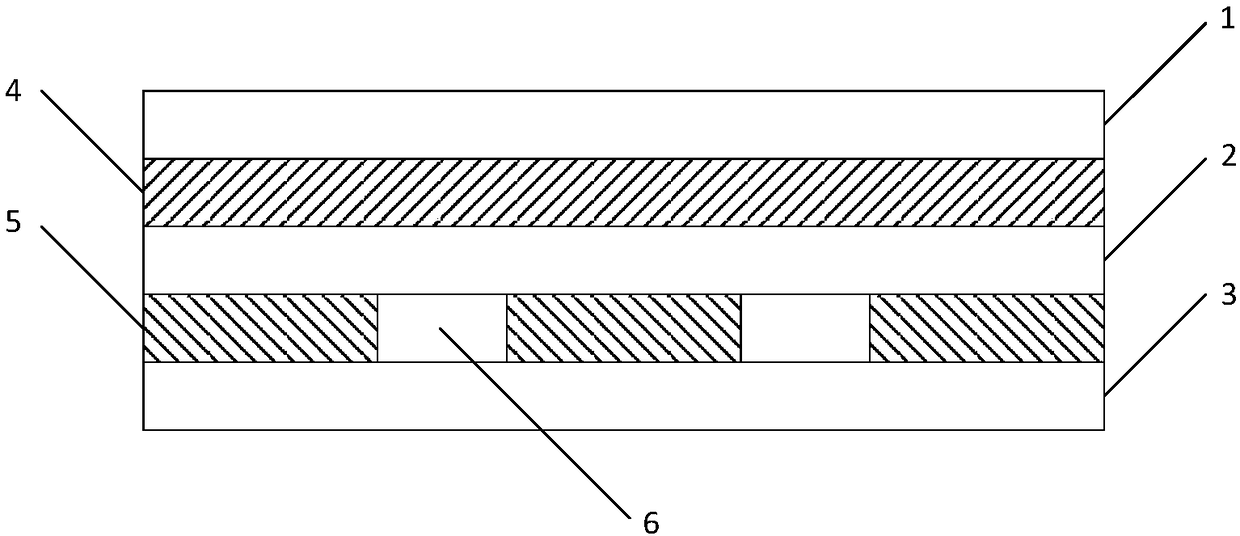

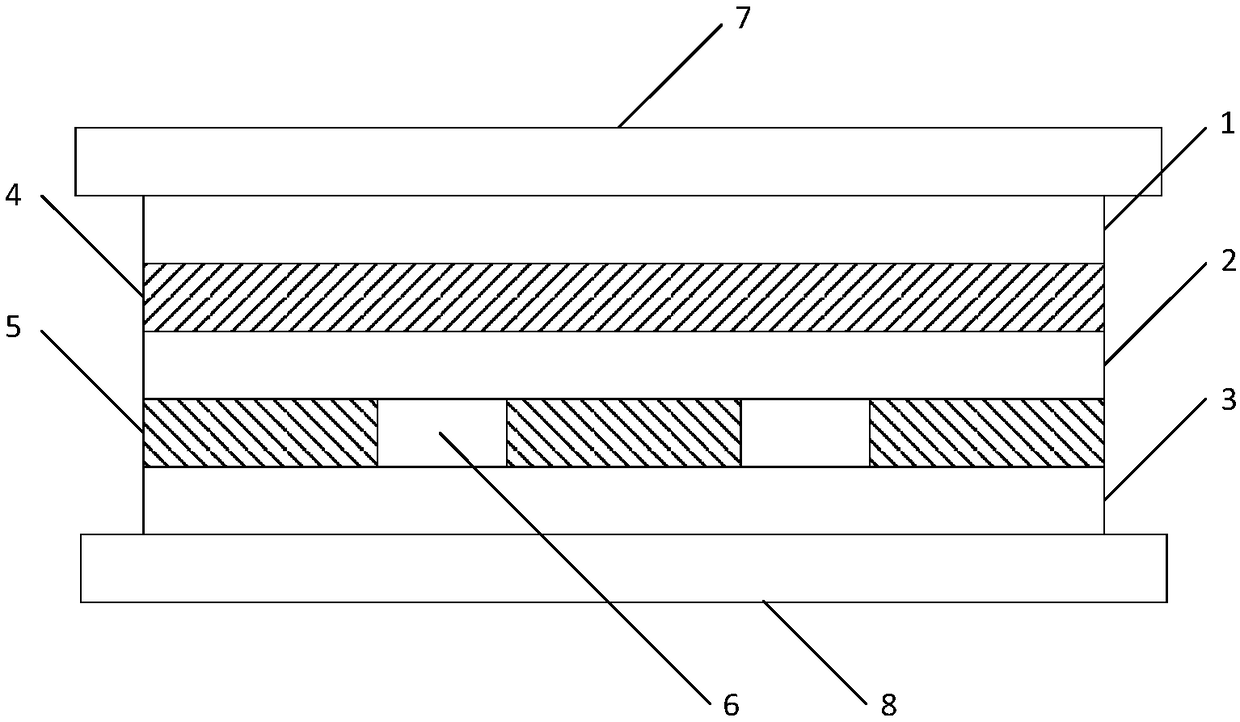

[0025] A touch pressure sensor provided by the present invention includes a first electrode layer, a second electrode layer and a third electrode layer arranged at intervals in sequence; wherein the first electrode layer includes at least one conductive film layer, and the second electrode layer and Capacitors are formed between the third electrode layers; and a second isolation layer is arranged between the second electrode layer and the third electrode layer, and an air gap is arranged in the second isolation layer. The above-mentioned first electrode layer includes a conductive film layer, which can form a capacitance between the part touched by the user in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com