Quality detection method, system, storage medium and equipment for flat film product

A quality testing method and testing system technology, applied in the field of quality testing of flat film products, can solve problems such as large workload and low efficiency, and achieve the effect of reducing workload, simplifying screening process, and speeding up progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

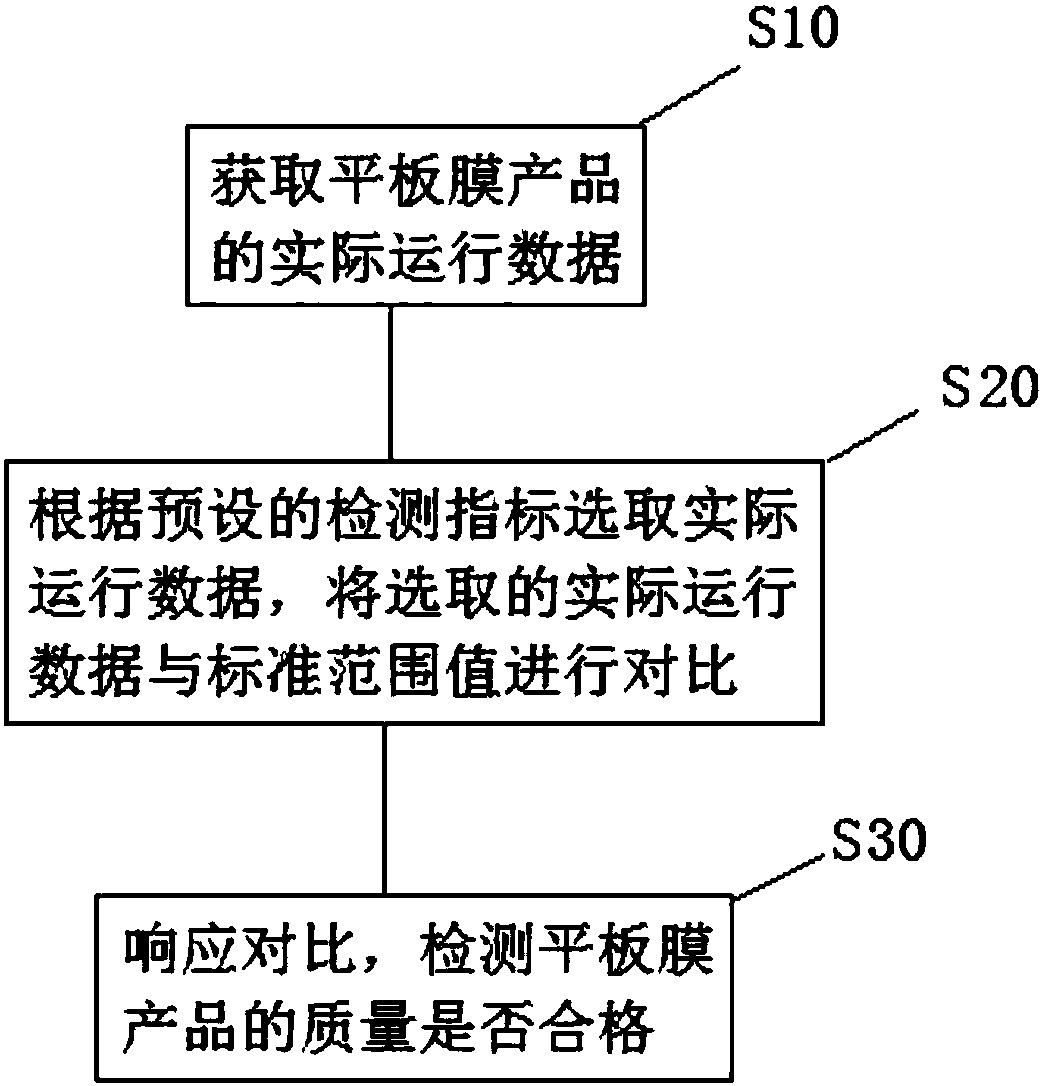

[0030] The embodiments of the present invention provide a quality detection method for flat membrane products, which is suitable for the research and development process or production process of microfiltration membranes and ultrafiltration membranes, such as figure 1 Shown, the quality inspection method of this flat film product comprises the steps:

[0031] Step S10: Obtain the actual operating data of the flat film product;

[0032] Step S20: Select actual operating data according to preset detection indicators, and compare the selected actual operating data with the standard range value;

[0033] Step S30: Response comparison, check whether the quality of the flat film product is qualified.

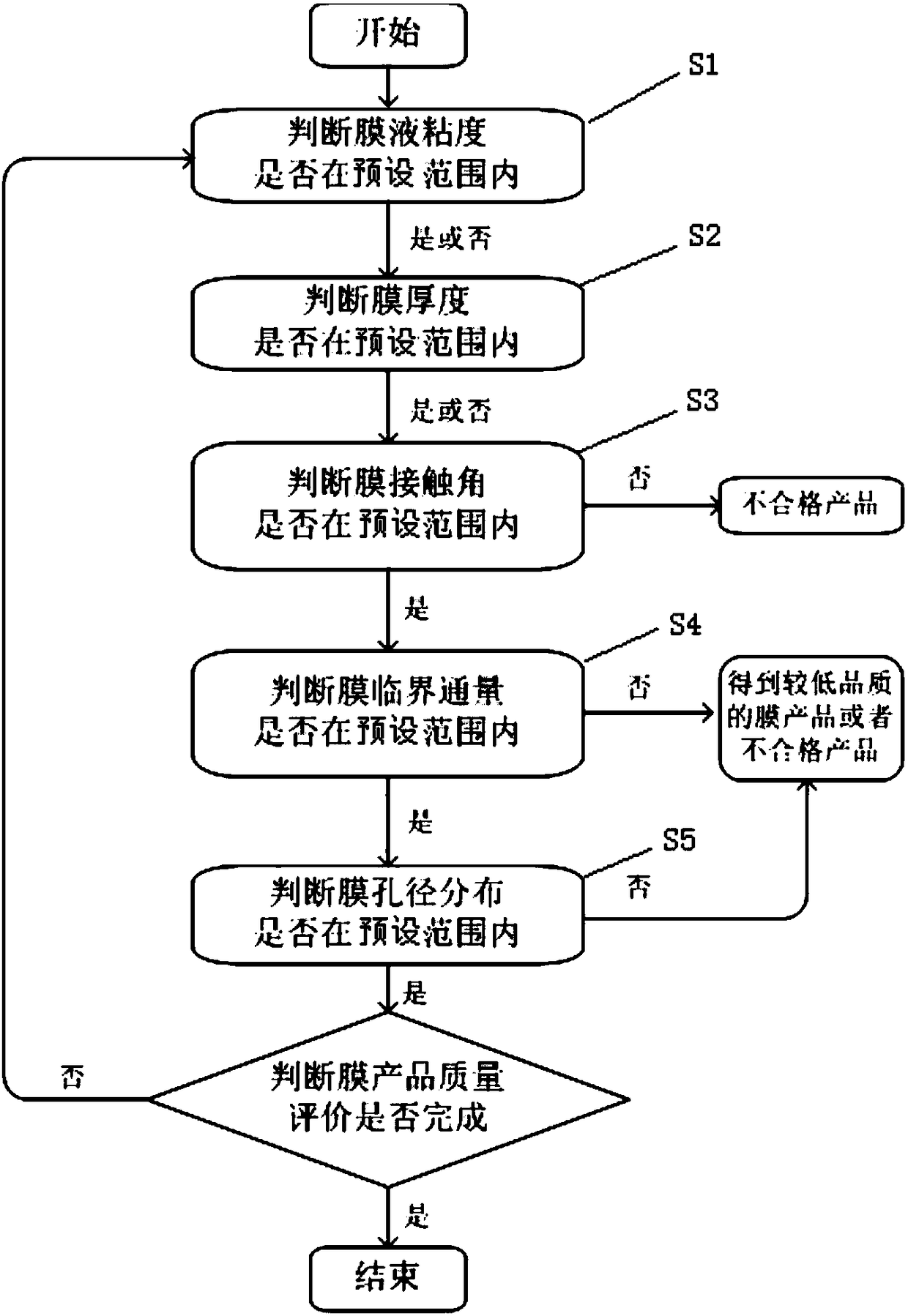

[0034] In a preferred embodiment, the detection index of the membrane product is determined according to the actual operation data and the preset large database of flat membrane products by using the mathematical simulation induction method and / or the statistical analysis method. In...

Embodiment 2

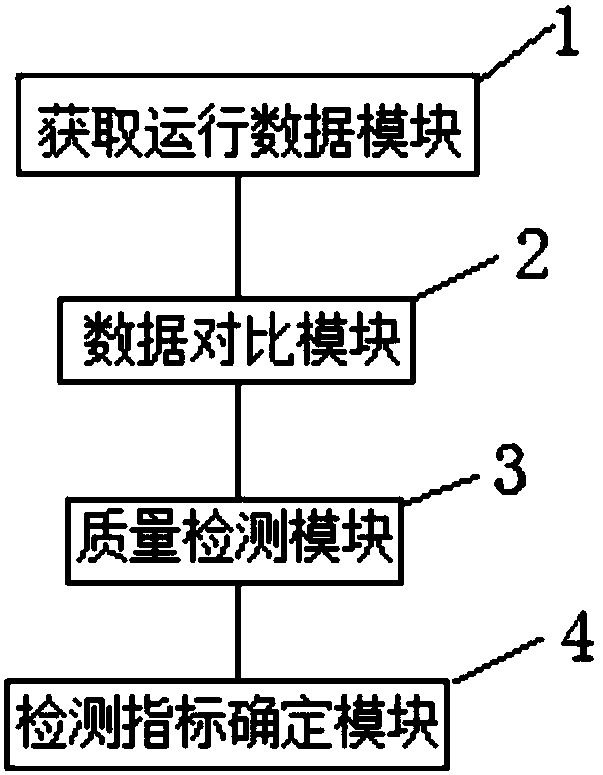

[0051] Embodiments of the present invention provide a quality detection system for flat film products, such as image 3 As shown, the quality inspection system of the flat film product includes: obtaining operation data module 1, which is used to obtain the actual operation data of the flat film product; data comparison module 2, which is used to select the actual operation data according to the preset detection index, and will select The actual operation data is compared with the standard range value; the quality inspection module 3 is used for response comparison to detect whether the quality of the flat film product is qualified; the detection index determination module 4 is used for using mathematical simulation induction method and / or statistical analysis method, according to the actual operation data and the preset large database of flat membrane products to determine the detection index of the membrane product.

[0052] In the embodiment of the present invention, a larg...

Embodiment 3

[0058]An embodiment of the present invention provides a non-transitory computer-readable storage medium. The readable storage medium stores computer instructions. When the computer instructions are executed by a processor, the quality detection method for a flat film product as in Embodiment 1 is implemented. Wherein, the storage medium may be a magnetic disk, an optical disk, a read-only memory (Read-Only Memory, ROM), a random access memory (Random Access Memory, RAM), a flash memory (Flash Memory), a hard disk (Hard Disk Drive, Abbreviation: HDD) or solid-state drive (Solid-State Drive, SSD), etc.; the storage medium may also include a combination of the above-mentioned types of storage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com