Safety control system for 30000Psi ultrahigh pressure wellhead

A safety control, ultra-high pressure technology, applied in wellbore/well components, wellbore/well valve devices, earthwork drilling and production, etc., can solve the problems of inability to realize full electro-hydraulic automatic control, and achieve full electro-hydraulic automation Control and meet the effect of development and production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

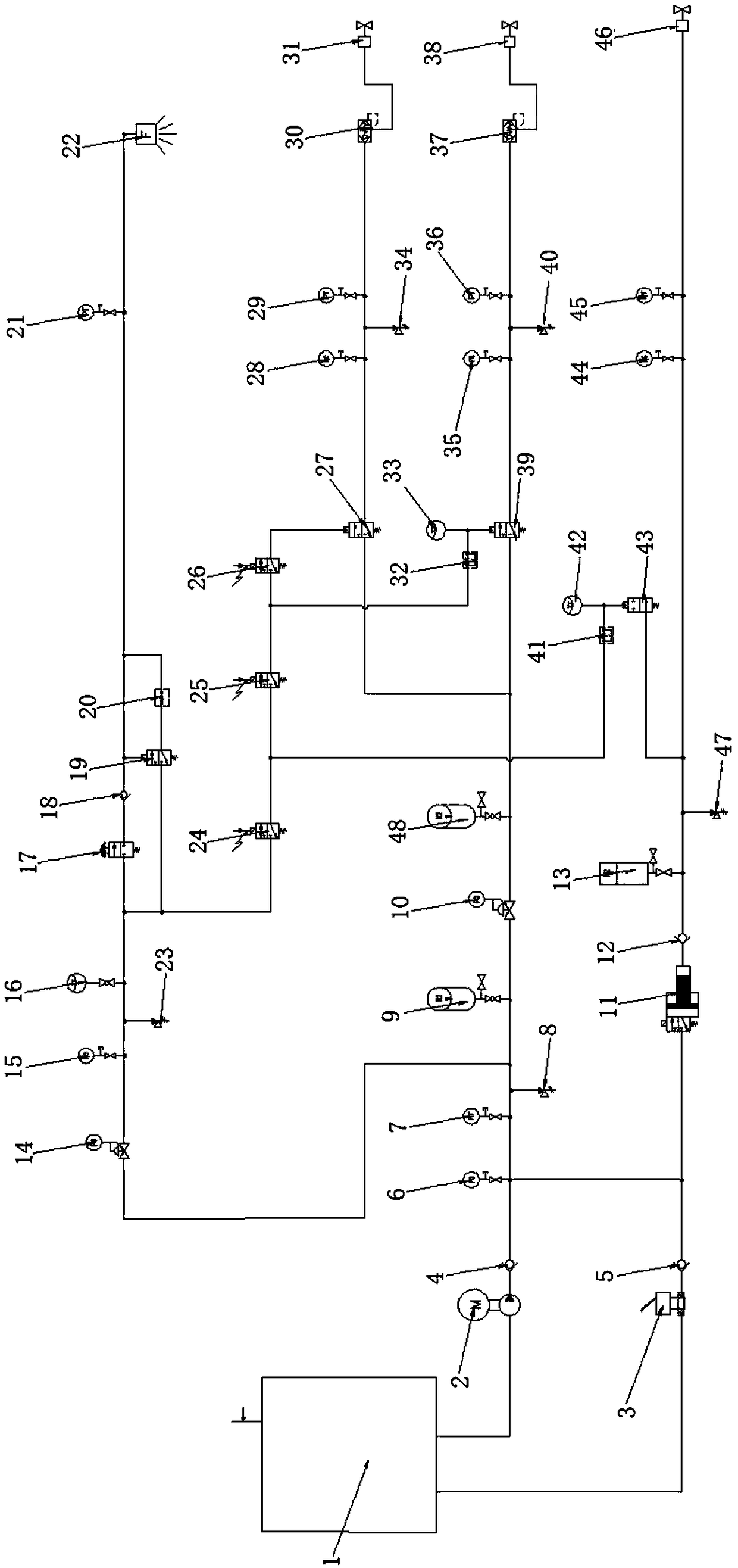

[0024] as attached figure 1 As shown, a 30000Psi ultra-high pressure wellhead safety control system includes a high-pressure hydraulic system, an ultra-high pressure downhole safety valve hydraulic control main circuit, and a low pressure control system.

[0025] The high-pressure hydraulic system is used as the power source of the hydraulic control main road of the safety valve on the well and the main road of the hydraulic control of the ultra-high pressure downhole safety valve. Table 6, the fourth pressure transmitter 7, the fourth safety valve 8, the first accumulator 9, and the first pressure regulating valve 10. Secondly, the high-pressure hydraulic system also includes a backup system, the backup system is connected in parallel with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com