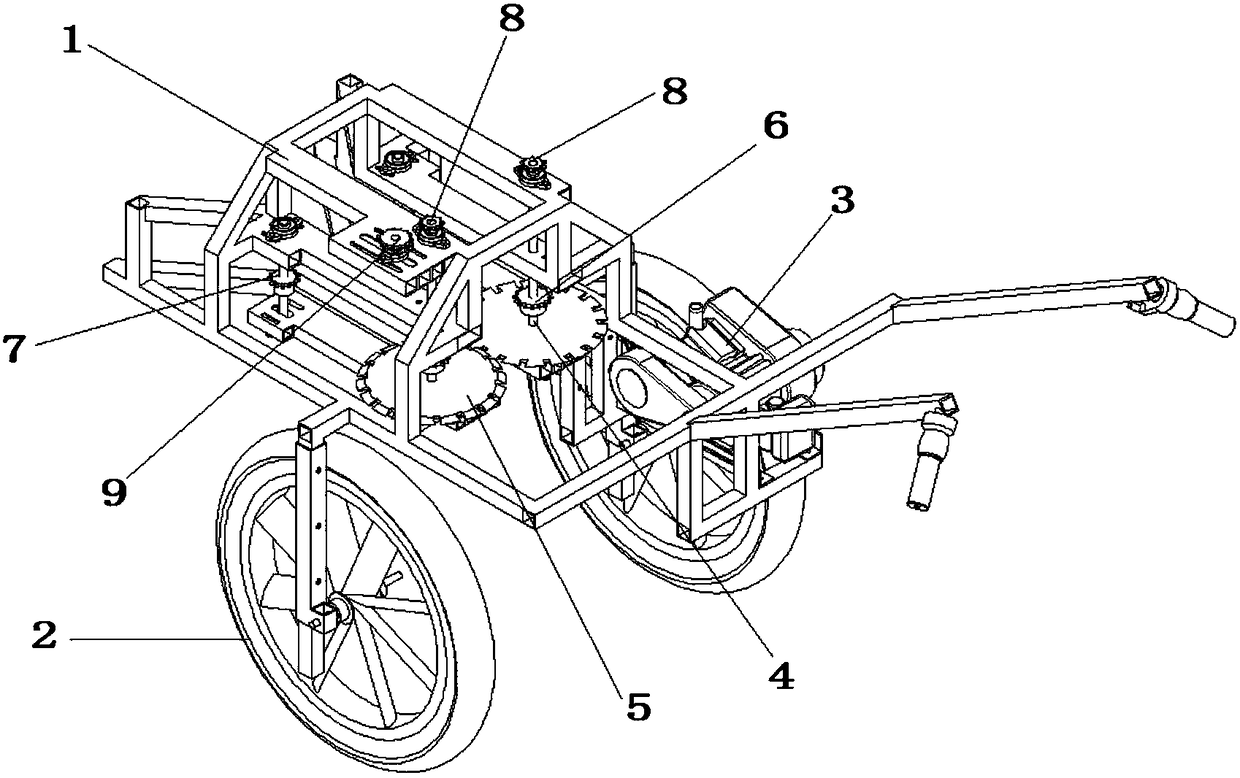

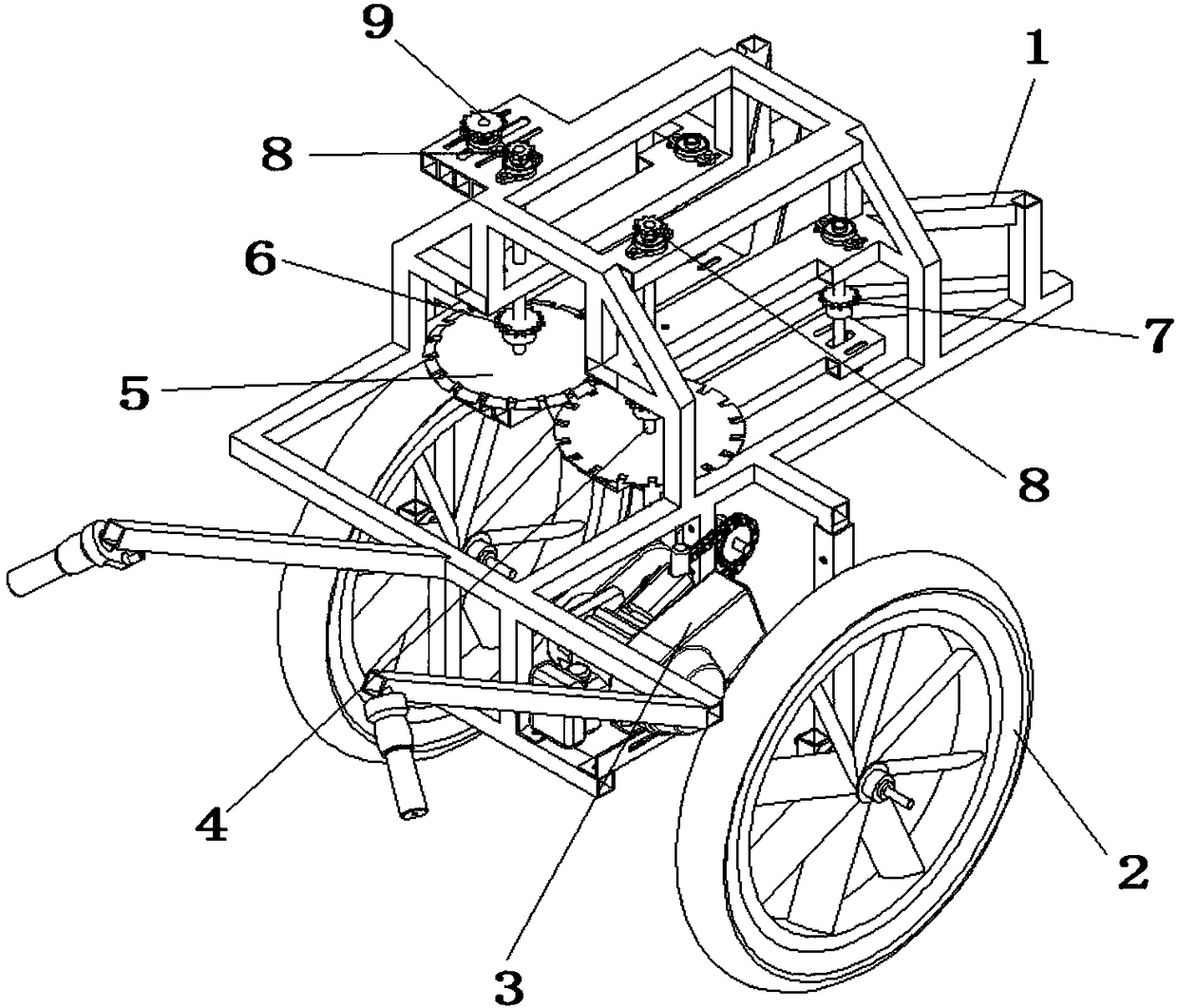

Walking type pineapple harvester

A harvester, walk-behind technology, applied in the field of walk-behind pineapple harvesters, can solve the problem that the pineapple is not suitable for the harvester, achieve the effect of simple and controlled forward and steering, small and simple overall structure, and improve harvesting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A kind of walk-behind pineapple harvester, comprises vehicle frame 1, wheel 2, engine 3, cutterhead 5, cutterhead shaft 4, transmission mechanism, rotating mechanism; Described vehicle frame 1 is welded by square steel pipe, and intensity is high, The weight is light, the wheels 2 are connected to the vehicle frame 1, the engine 3 is arranged on the vehicle frame 1, the cutterhead shaft 4 is rotatably fixed on the vehicle frame 1, the cutterhead 5 is detachably fixed on the cutterhead shaft 4, and the engine 3 Drive the cutterhead shaft 4 on the side close to the engine 3 to rotate through the transmission mechanism, and the cutterhead shaft 4 on the side close to the engine 3 drives the cutterhead shaft 4 on the side away from the engine 3 to rotate in the opposite direction through the rotating mechanism, and the cutterhead 5 cuts the The tangent direction of the pineapple is the conveying direction of the pineapple. The engine 3 adopts a two-stroke gasoline engine and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com