Vibration speed prediction method for foundation pit static blasting close to structures

A static blasting and structure technology, applied in the field of construction, can solve the problems of inability to meet the requirements of on-site construction, high quality requirements of computing personnel, and long computing cycles, and achieve the effect of reducing the workload of on-site forecasting, speeding up the construction progress, and reducing forecasting costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific embodiment of the present invention will be further described in detail below in conjunction with the accompanying drawings.

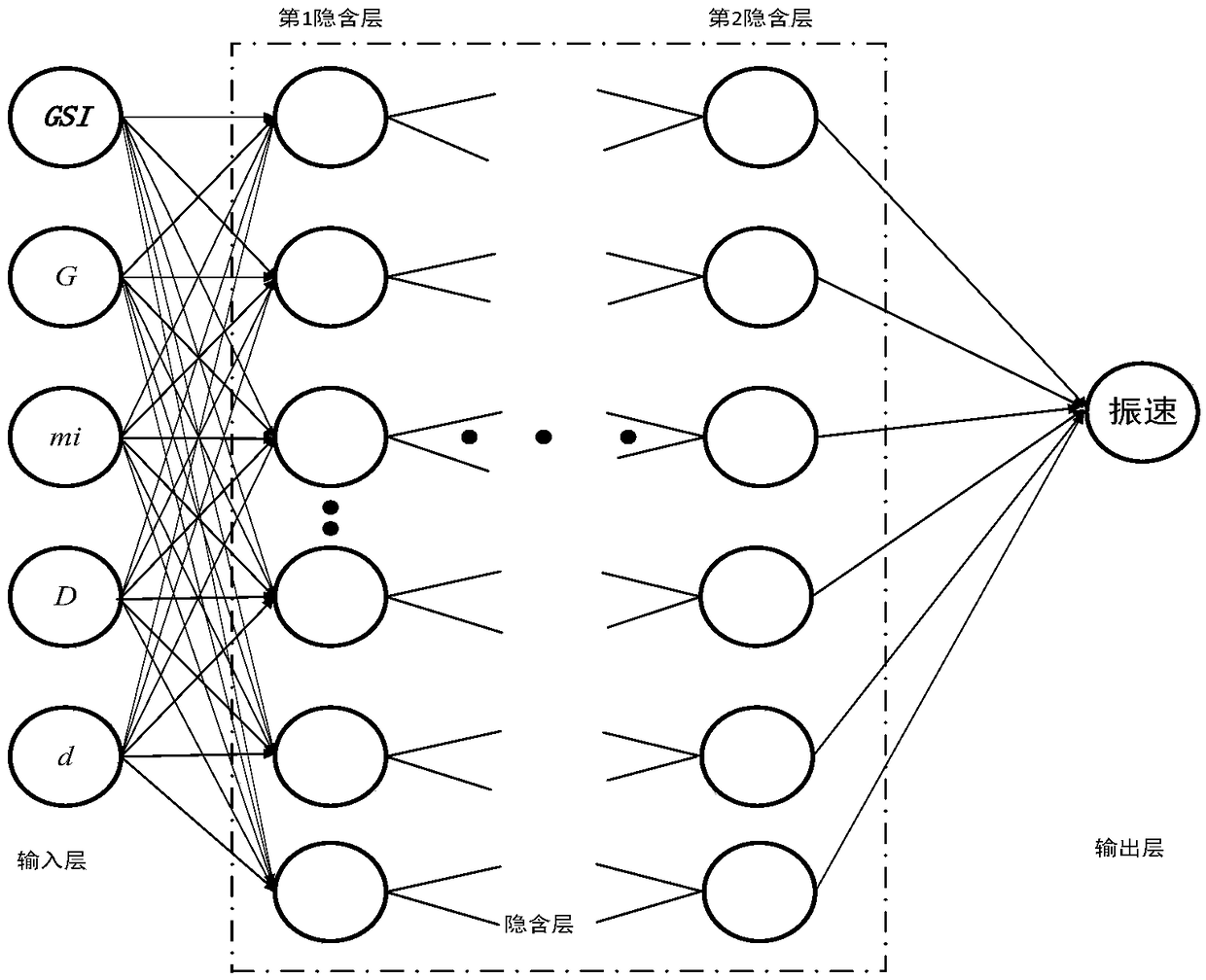

[0039] A vibration velocity prediction method for static blasting of a foundation pit adjacent to structures or pipelines, comprising the following steps:

[0040] Step S1: Determine the value range of parameters, the parameters include geological strength index GSI, rock hardness m i , the degree of rock disturbance D, the amount of charge G and the distance d between the charge hole and the adjacent structure or pipeline.

[0041] Geological strength index GSI, rock hardness degree m i , The upper and lower bounds of rock disturbance degree D can be obtained according to relevant geological survey reports or query design manuals. The upper and lower bounds of the charge amount G and the distance d between the charge hole and the adjacent structure or pipeline are determined according to the requirements of the construction site....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com