Clothes drying machine steel wire rope installation method and steel wire rope installation device

A technology of installation device and installation method, which is applied to washing devices, hoisting devices, other drying devices, etc., can solve the problems of difficult assembly operation, long time-consuming, and easily messy lines, so as to save production site space and improve quality. Stability, the effect of simplifying the installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0043] Such as Figure 10 As shown, a method for installing a wire rope of a clothes dryer in this embodiment includes:

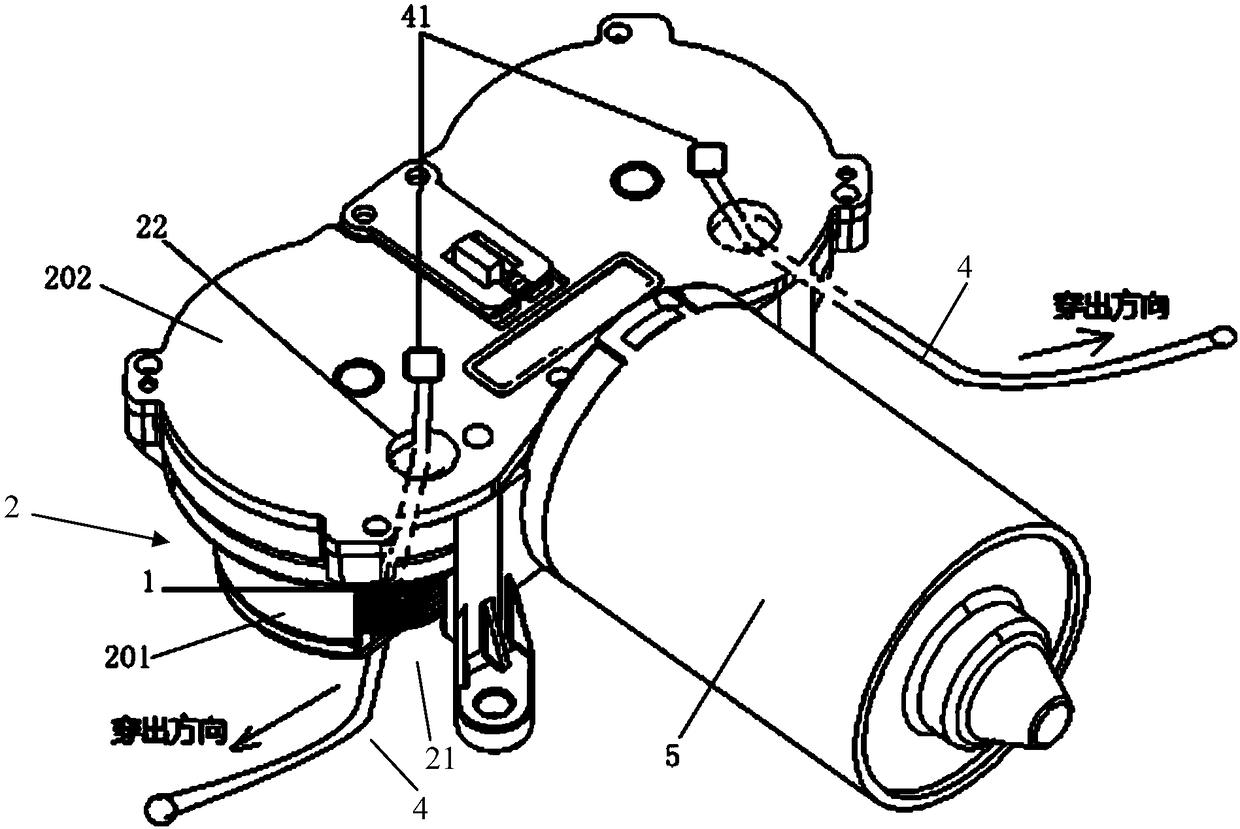

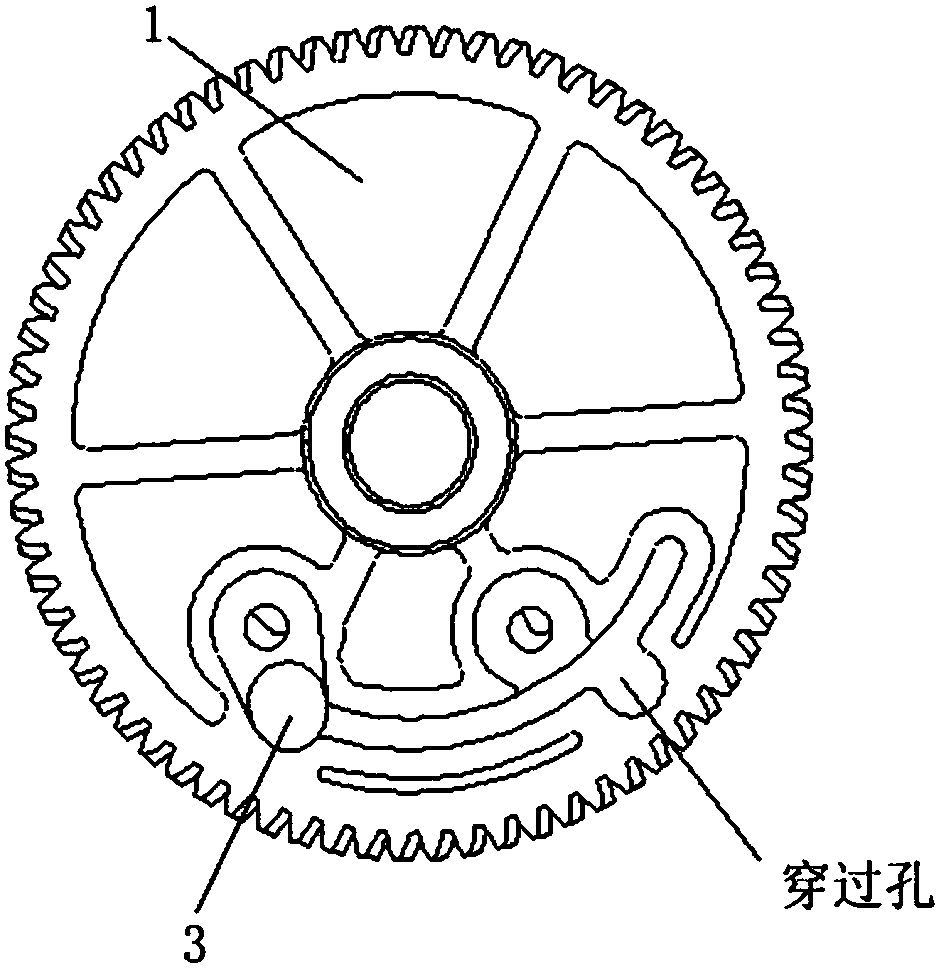

[0044] Pass the steel wire rope 4 through the wire passing structure of the motor assembly, and use the end 41 at the end of the steel wire rope 4 to buckle back into the fixing hole 3 (such as image 3 , 6 , 9 shown);

[0045] The motor 5 drives the reel to rotate, and the reel winds the wire rope 4;

[0046] Control the starting and stopping of the motor 5 corresponding to the reel, adjust the rotation amount of the two reels on the left and right, so that the extensions of the two steel ropes 4 on the left and right are equal.

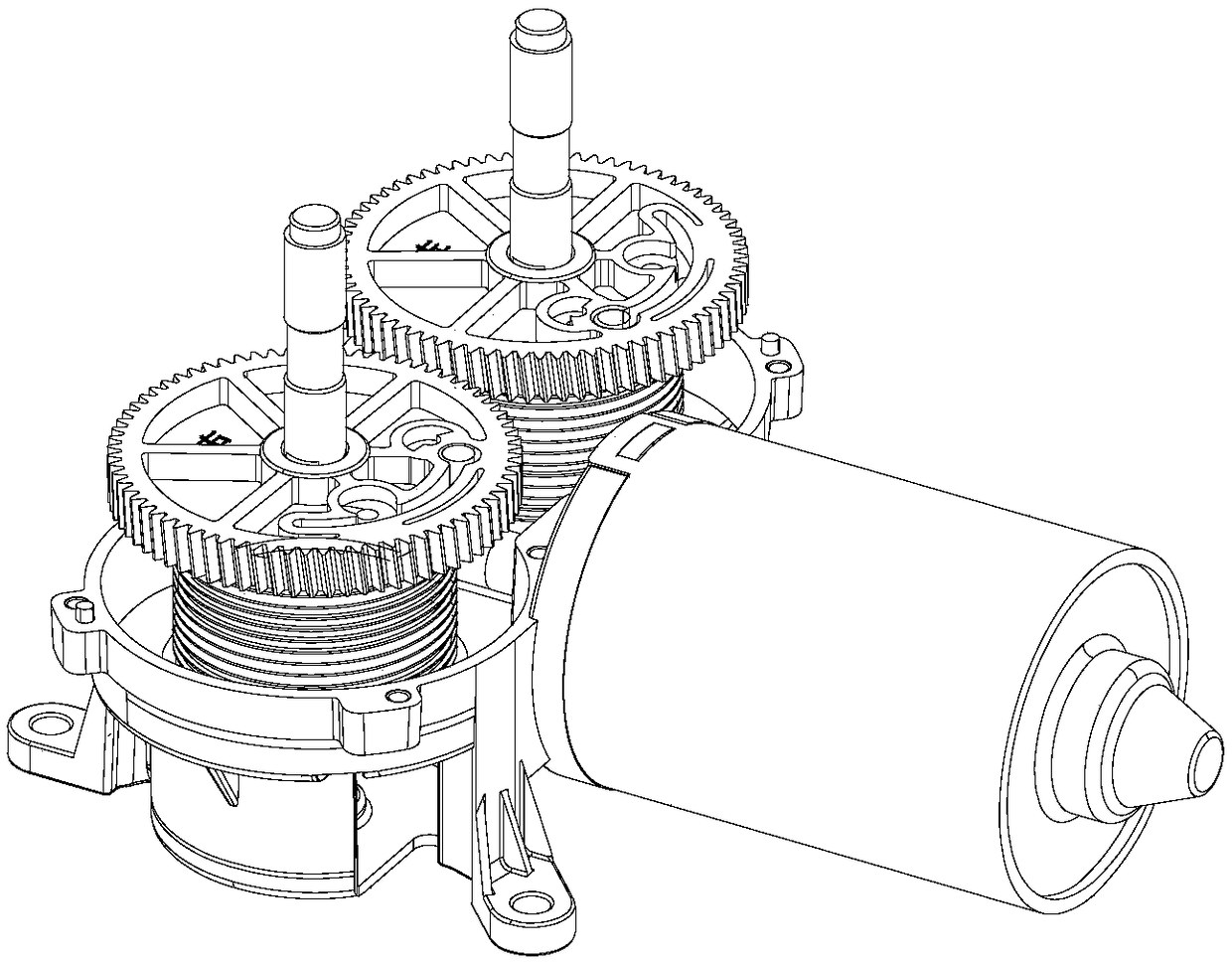

[0047] Wherein, the motor assembly is an assembly including the motor 5 , the reel 1 , and the gearbox housing 201 . In this way, the left reel and the right reel can be respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com