Device for rapidly measuring surface flatness of object

A technology of object surface and measuring device, applied in the fields of production, inspection, machinery, testing, industry and optics, which can solve the problems of over-specialized theoretical foundation, influence of measurement accuracy, and lack of suppression means.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 2

[0078] This embodiment is an embodiment of the device for quickly measuring the surface flatness of an object of the present invention.

[0079] The device for quickly measuring the flatness of the object surface in this embodiment is further defined on the basis of the first embodiment: the exposure time of the image sensor 1-9 is the same as the stagnation time of the stage 1-3.

specific Embodiment 3

[0080] This embodiment is an embodiment of the method for quickly measuring the surface flatness of an object according to the present invention.

[0081] The method for quickly measuring the flatness of the surface of the object in this embodiment of the present invention is implemented on the device for quickly measuring the flatness of the surface of the object described in the first embodiment or the second embodiment.

[0082] The method for quickly measuring the flatness of the object surface of the present invention comprises the following steps:

[0083] Step a. Adjust the measured object 1-6 so that a certain position on the upper surface of the measured object 1-6 is located at the focus position of the objective lens 1-4, and the limit protrusion 2-9 is required to be located at the moving block 2 The lowest point in the inferior arc slot in -3, the limit protrusion 2-9 is located at the lowest point of its motion track;

[0084] Step b, setting the imaging time t ...

specific Embodiment 4

[0097] This embodiment is an embodiment of the device for quickly measuring the surface flatness of an object of the present invention.

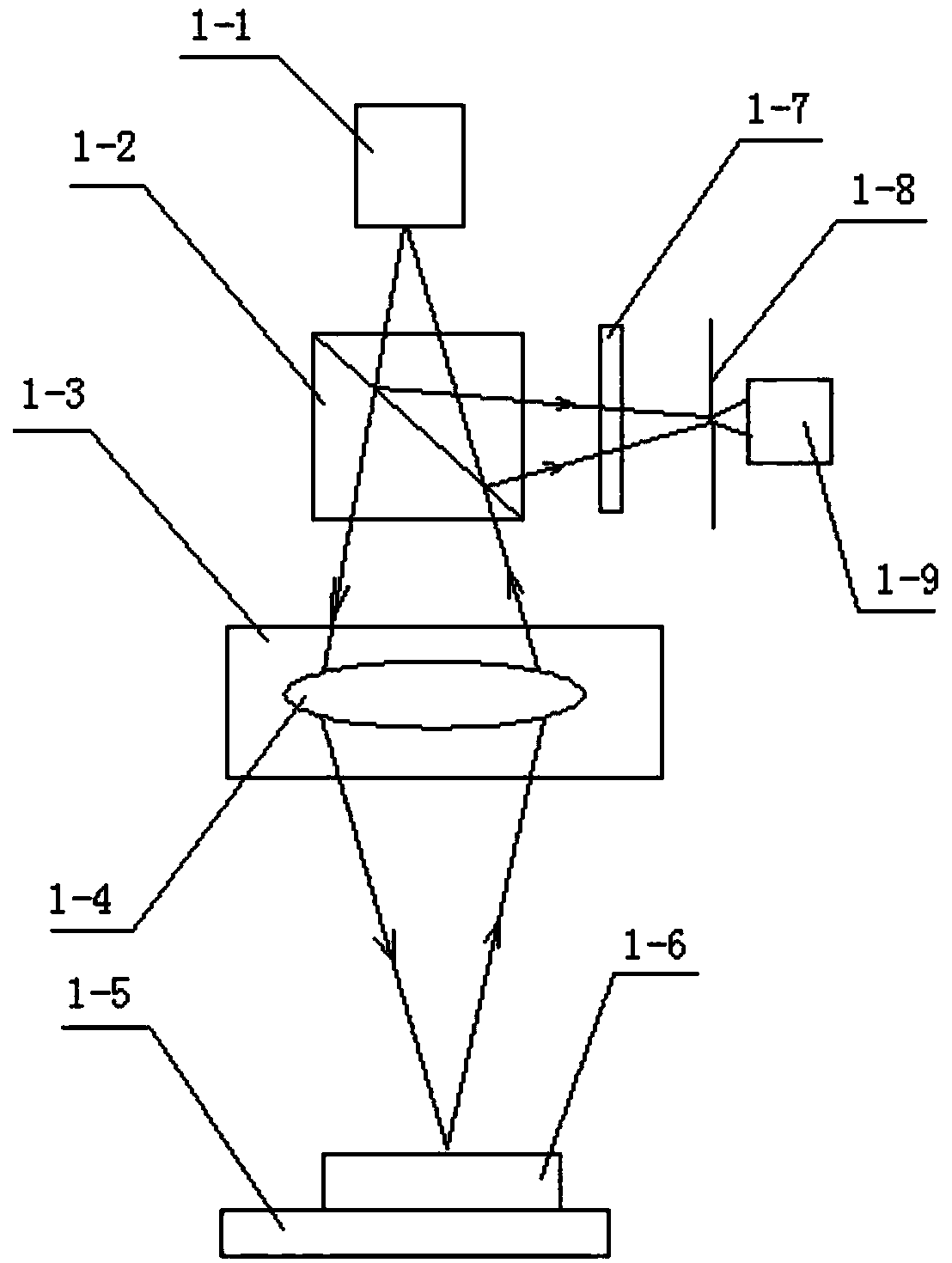

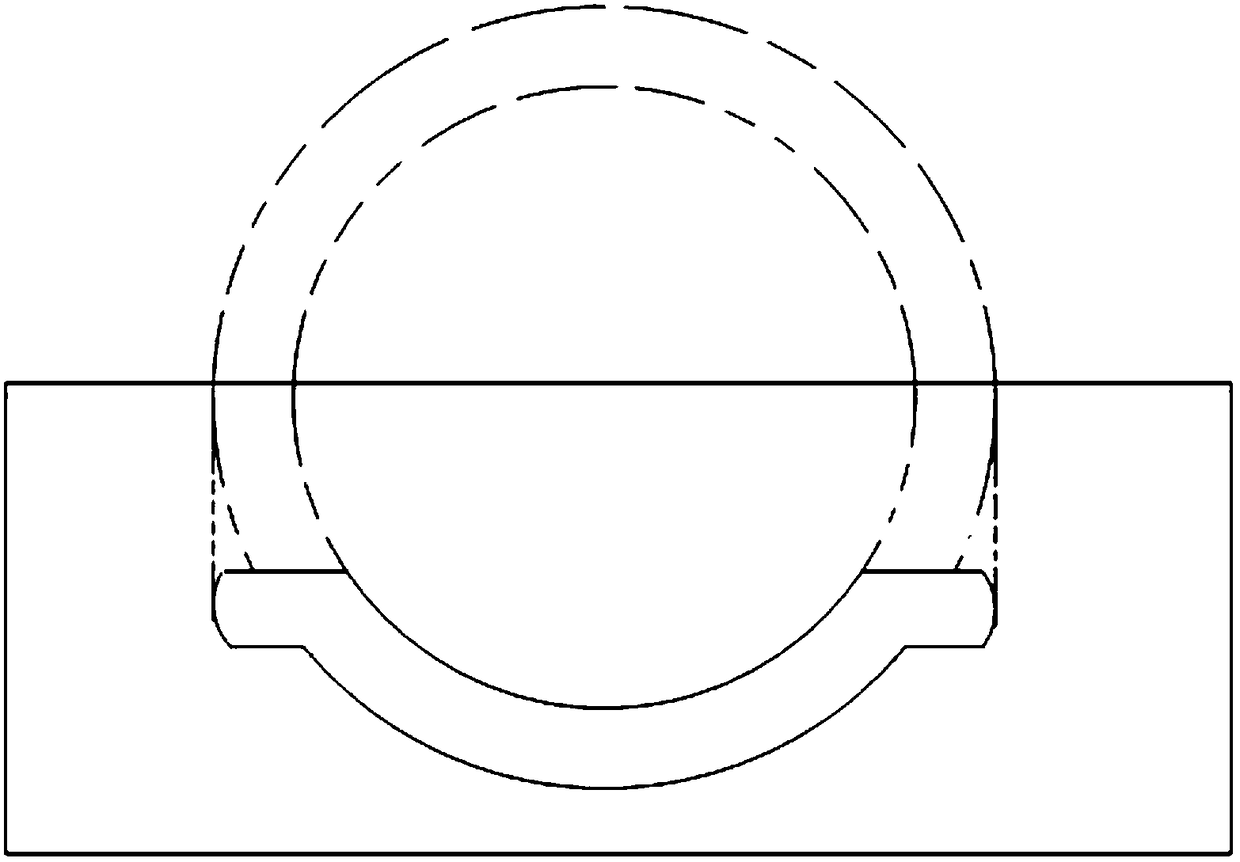

[0098] A rapid measuring device for surface flatness of an object, which is composed of an illumination imaging module and a motion mechanism; wherein, the schematic diagram of the illumination imaging module is as follows figure 1 As shown, the structure diagram of the motion mechanism is shown in figure 2 shown.

[0099] The illumination imaging module is composed of an illumination system and an imaging system; in the illumination system, a laser 1-1, a beam splitter 1-2, an objective lens 1-4, and a measured object 1-6 are sequentially arranged along the light propagation direction; The objective lens 1-4 is carried by the stage 1-3 and moves along the direction of the optical axis; the measured object 1-6 is carried by the two-dimensional translation stage 1-5 and moves two-dimensionally in the plane perpendicular to the optical axis;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com