Mechanical gear type stepless automatic transmission

An automatic transmission and gear type technology, applied in the transmission field, can solve the problems of inability to withstand large torque, engine power loss, and frustration, and achieve the effects of fast acceleration response, low cost and fast change speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

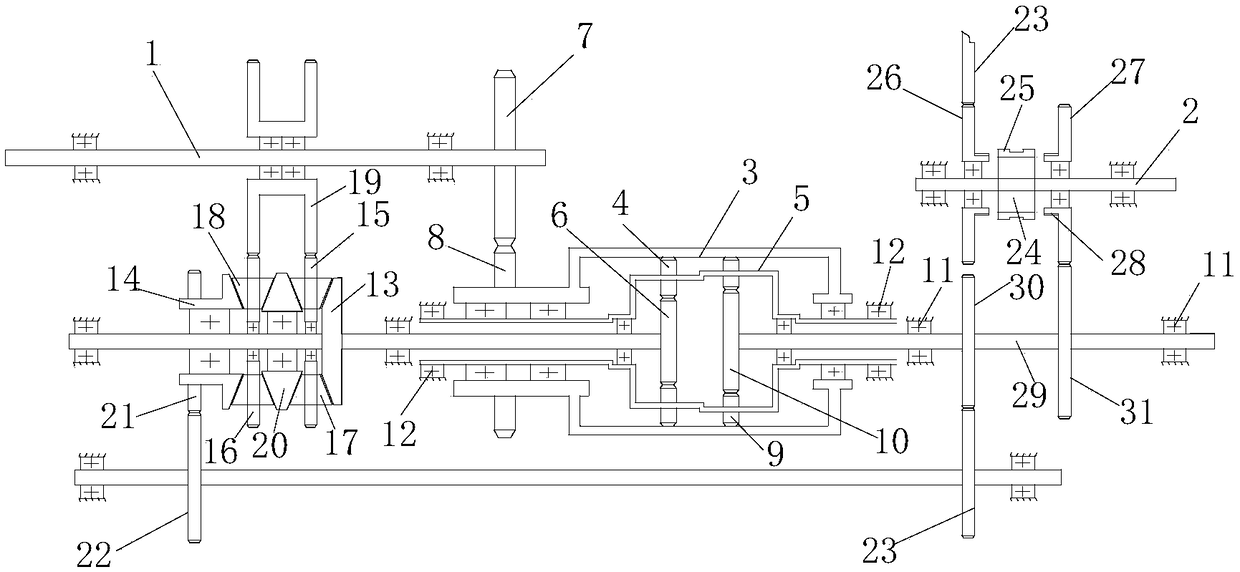

[0023] see figure 1 , the continuously variable automatic transmission provided by the present invention includes a casing, an input shaft 1 and an output shaft 2 sleeved on the casing, and also includes a first planetary row arranged inside the casing, and the input shaft 1 is fixedly connected with the first An input gear 7, the first ring gear 3 outer sleeve is fixed with the second input gear 8 which is constantly meshed with the first input gear 7, the first planetary row includes the first ring gear 3 meshing with the input shaft 2, a plurality of ( At least two) the first planetary gear 4, the first planetary carrier 5 and the first sun gear 6, the first planetary gear 4 is installed on the first planetary carrier 5 and is connected with the internal teeth of the first ring gear 3 and the first sun gear 6 respectively. The outer teeth of the first sun gear 6 are in constant mesh, the first sun gear 6 transmits power to the output shaft 2, and also includes a second plan...

Embodiment 2

[0026] The difference from Embodiment 1 is that it also includes a differential gear train arranged inside the housing. The differential gear train includes a driving side gear 13, a driven side gear 14, and a side-by-side The provided first gear 15 and the second gear 16 are installed on the first gear 15 and a plurality of (at least two) first bevel gears 17 that are constantly meshed with the drive side gear 13 and can rotate on the second gear 16 And a plurality of (at least two) second bevel gears 18 and dual gears 19 that can rotate, the axis of the first bevel gear 17 is perpendicular to the axis of the first gear 15, the axis of the second bevel gear 18 is perpendicular to the axis of the second gear 16 The axis is vertical, between the first gear 15 and the second gear 16, a double-sided side gear 20 is arranged in the housing, the axis of the double-sided side gear 20 coincides with the axis of the first gear 15, and the side of the double-sided side gear 20 It is co...

Embodiment 3

[0030] The difference from Embodiment 2 is that this embodiment also includes a shifting assembly installed in the housing, and the shifting assembly includes an external spline 24 coaxially fixedly connected to the output shaft 2 , an external spline sleeved on the external spline 24 Inner spline sliding sleeve 25, the first output gear 26 and the second output gear 27 that are positioned at outer spline 24 both sides, first output gear 26 and second output gear 27 are all provided with inner spline sliding sleeve 25 The matching sliding shaft 28; the fifth gear 23 is in constant mesh with the first output gear 26, and the transmission shaft 29 is also fixedly provided with a seventh gear 31, which is in constant mesh with the second output gear 27. When the inner spline slides When the sleeve 25 is combined with the first output gear 26, the external spline 24 drives the output shaft 2 to rotate forward; when the internal spline sliding sleeve 25 is combined with the second o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com