An anti-shifting crushed stone backfill device and construction method

A technology of crushing stones and fixing steel plates, which is applied in the direction of filling, etc., can solve the problems of long construction period and high labor intensity, and achieve the effect of simplifying the installation operation steps, convenient use and operation, and easy movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

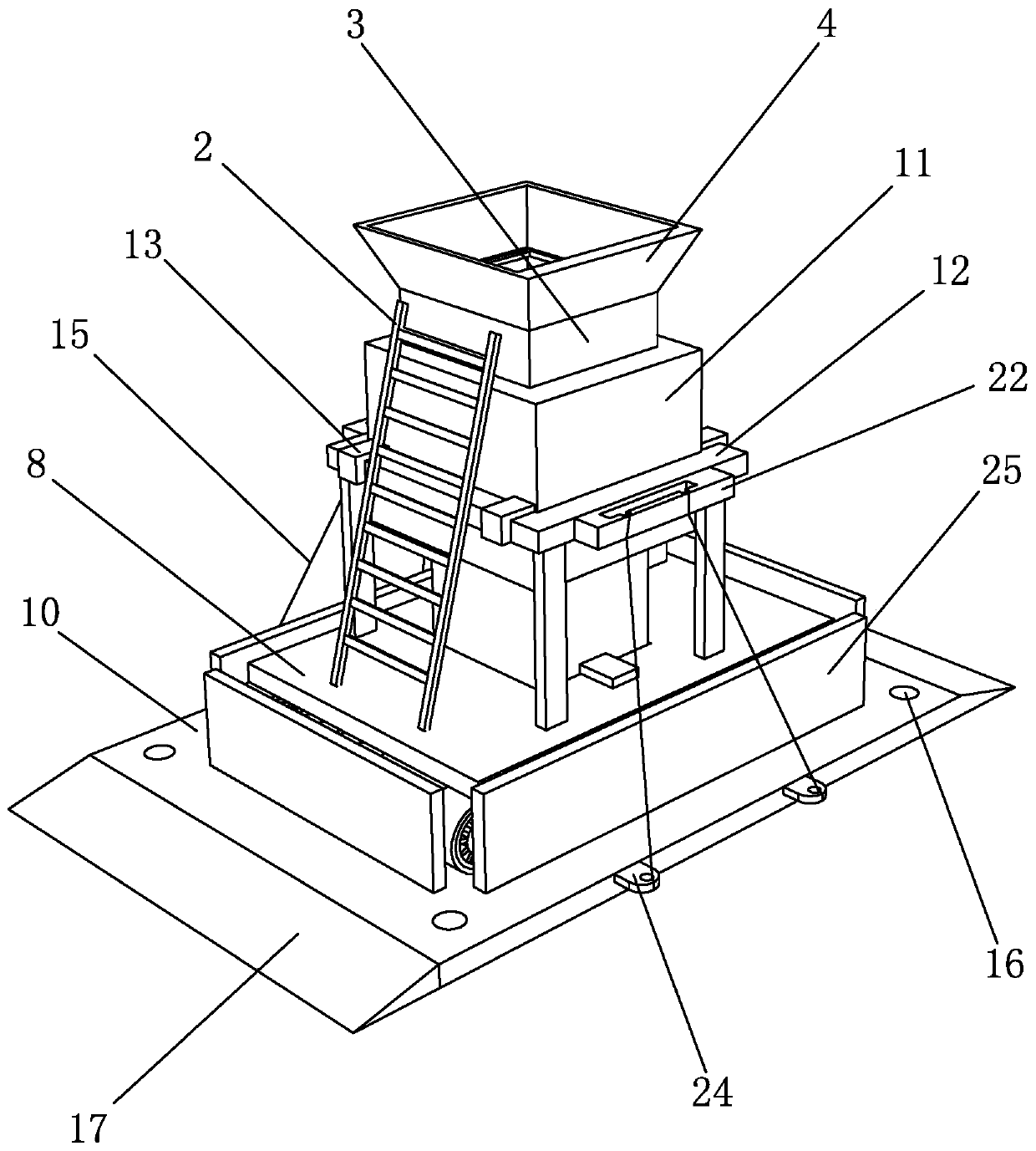

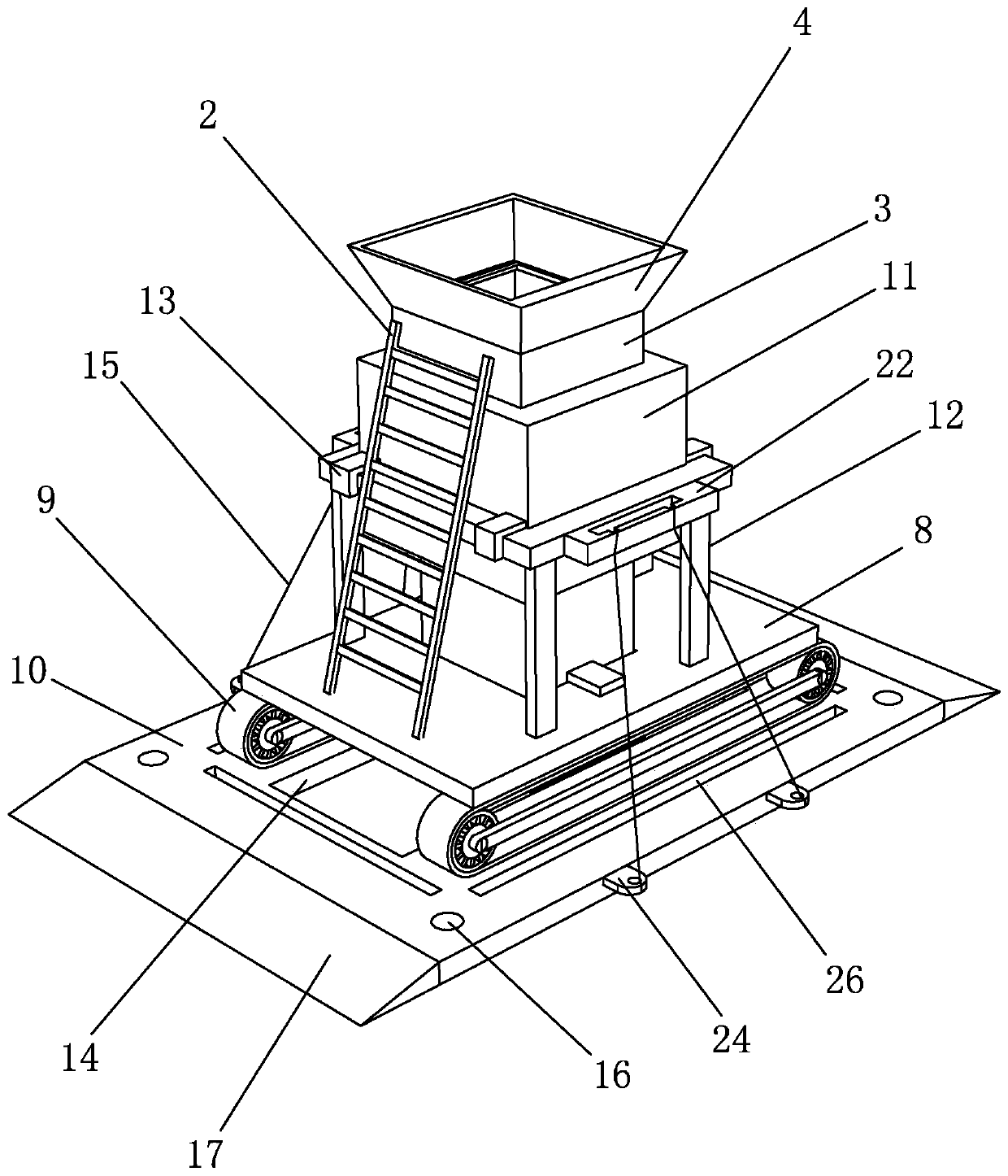

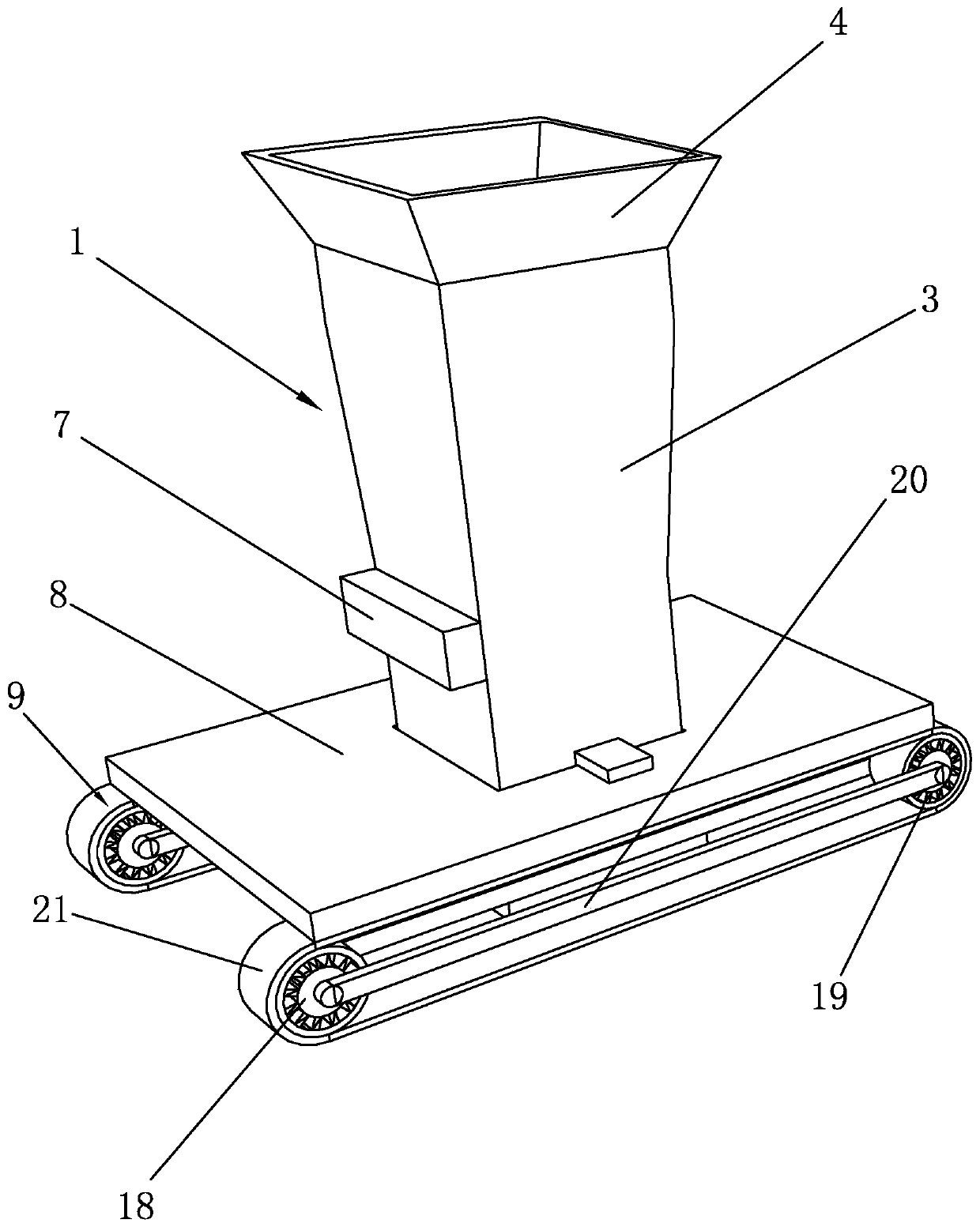

[0044] Such as Figure 1 to Figure 5 As shown, it is an anti-displacement gravel backfill device of the present invention, which includes a backfill body 1, a mobile handrail 2 and a fixing device. The design of the mobile handrail 2 can facilitate actual installation and subsequent maintenance and repair, and the design is more humane. The backfill body 1 includes a backfill box 3 and a mobile base 8, a feed hopper 4 is arranged above the backfill box 3, and a discharge hopper 5 is arranged below the backfill box 3, and the discharge hopper 5 and the feed hopper 4 are connected to each other. The backfill box 3 is movable and disassembled, and the upper end of the discharge hopper 5 is provided with a crease section 6. The design of the crease section 6 can stretch the length of the discharge hopper 5 according to the thickness of the fixed steel plate 10 to ensure that the bottom of the discharge hopper 5 Located in the gravel foundation pit, the feed hopper 4 is in the shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com