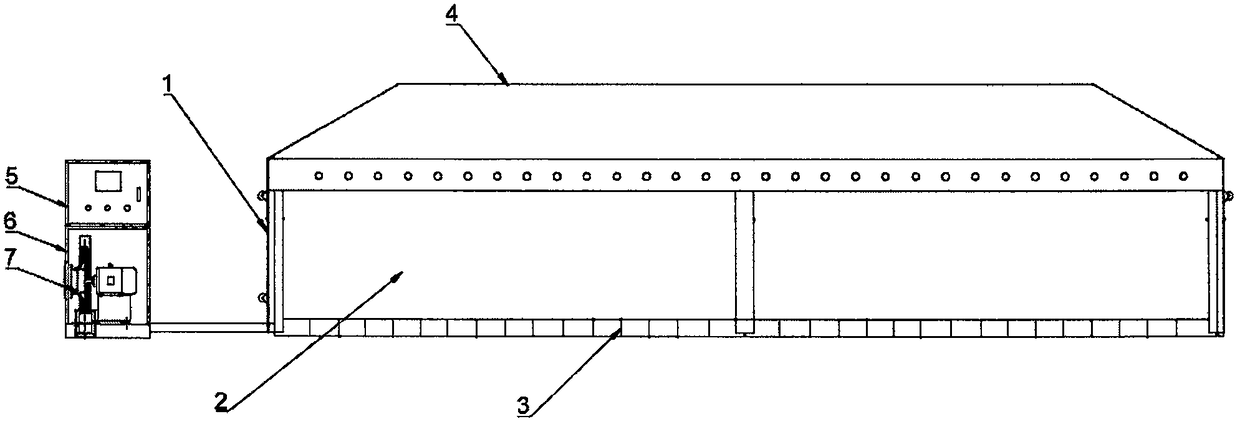

Fabricated aerobic composting device

An aerobic composting and prefabricated technology, which is applied in fertilization devices, organic fertilizers, chemical fertilizer treatment control and other directions, can solve the problems of large climate impact, large area of static composting system, and increased area. Simple assembly and disassembly process, flexible and adjustable dwell time, avoid redundant and wasteful effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

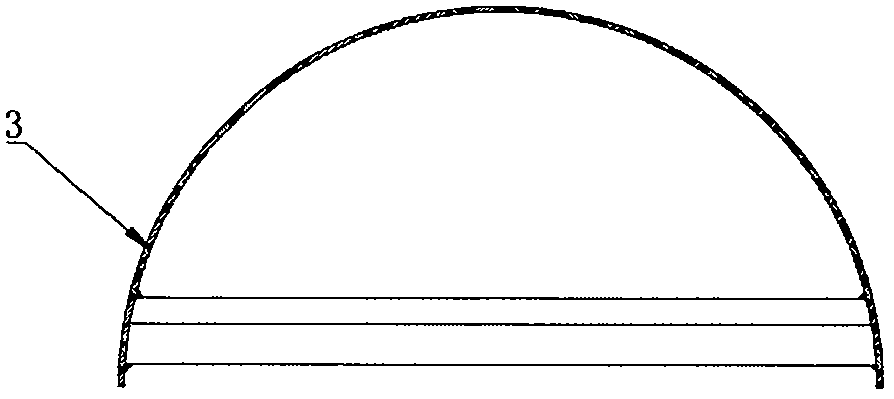

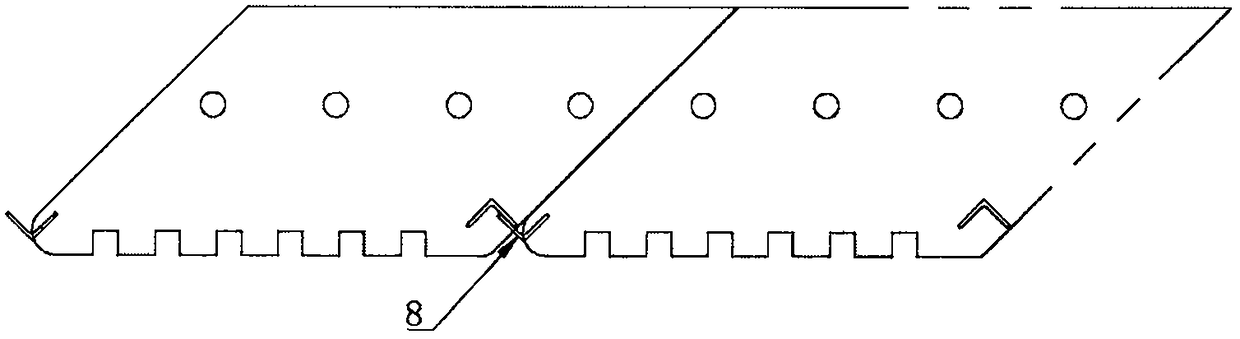

[0019] Reference will now be made in detail to the exemplary embodiments, examples of which are illustrated in the accompanying drawings. When the following description refers to the accompanying drawings, the same numerals in different drawings refer to the same or similar elements unless otherwise indicated. The implementations described in the following exemplary examples do not represent all implementations consistent with the present invention. Rather, they are merely examples of apparatuses and methods consistent with aspects of the invention as recited in the appended claims.

[0020] The most important point in the implementation of the whole device is the assemblability. Each monomer is independent, and composting devices of different scales can be built through assembly. This prefabricated concept makes the process of building and disassembling very simple and clear. The specific implementation method is as follows:

[0021] First of all, the warehouse body, aerati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com