Gas-liquid-dust explosion experiment system for use under multiple working conditions

A dust explosion and experimental system technology, applied in the field of explosion experimental systems, can solve problems such as in-depth research on the evolution mechanism and laws, inability to fully simulate factory explosions, and inability to timely and effectively propose new methods for suppressing explosions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to enable those skilled in the art to better understand the technical solution of the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

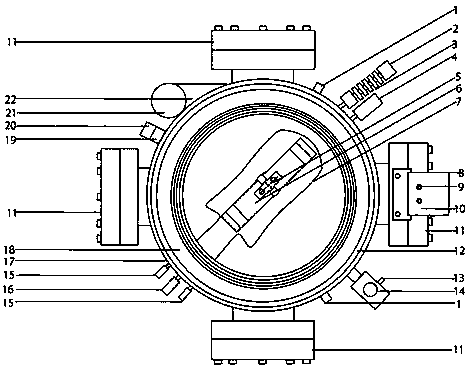

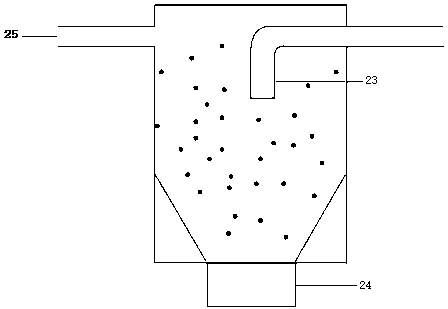

[0029] The invention discloses an experimental system for gas, liquid and dust explosions under various working conditions, which comprises a container main body, a material temperature control unit respectively arranged on the container main body, an inner container temperature control unit, a precision electric spark Ignition energy generation unit, gas concentration test unit, humidity control unit, pressure sensor unit, flame temperature sensor unit and air intake and vacuum unit, the container body includes an inner container made of 316 stainless steel and 304 or 316 stainless steel The outer container made of material, the wall thickness of the inner container is 5-15mm, the wall thickness of the outer contain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com