Factory prefabricated floor slab structure

A factory prefabrication and construction technology, which is applied in the field of prefabricated building components, can solve problems such as poor waterproof performance, poor integrity, and inappropriateness, and achieve the effects of reducing size costs, strong structural stress integrity, and speeding up installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

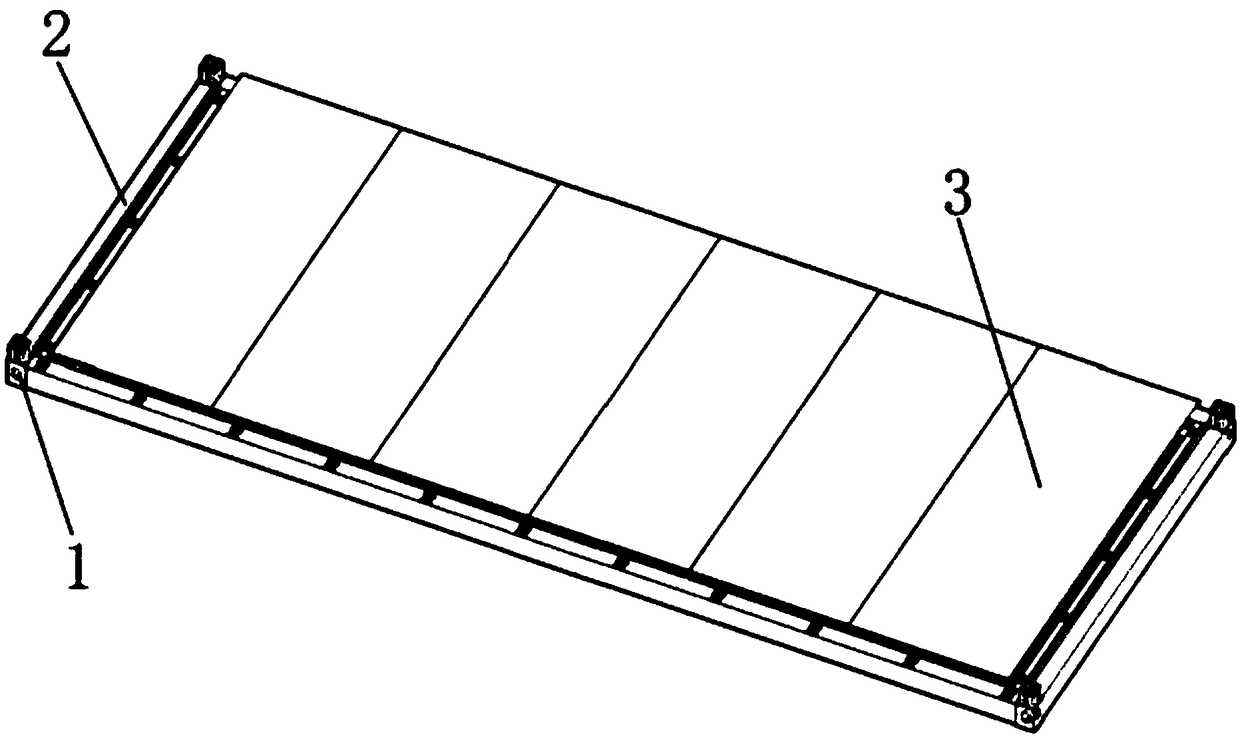

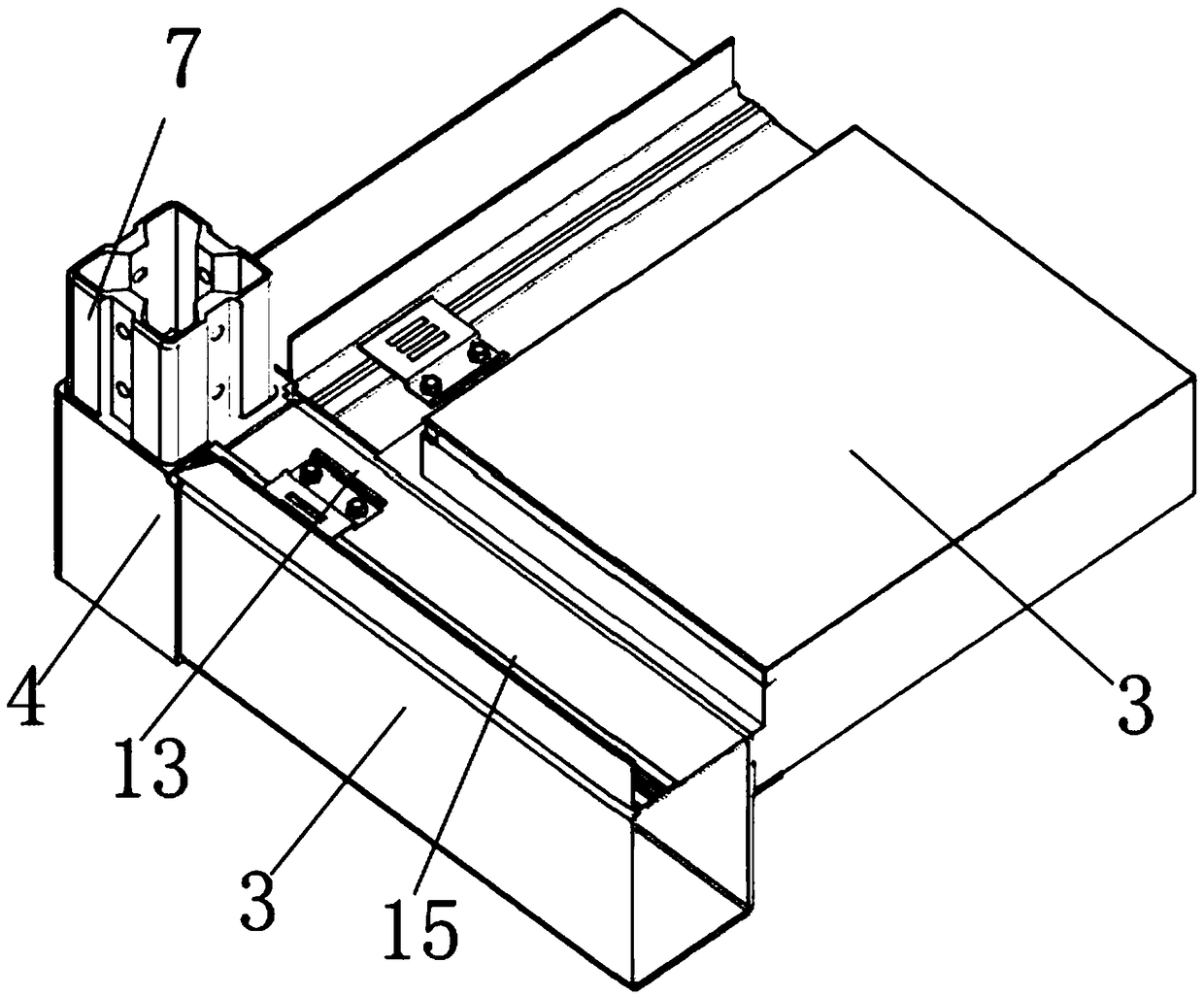

[0024] Attached below Figure 2-9 Shown is a further description of a factory prefabricated floor structure of the present invention.

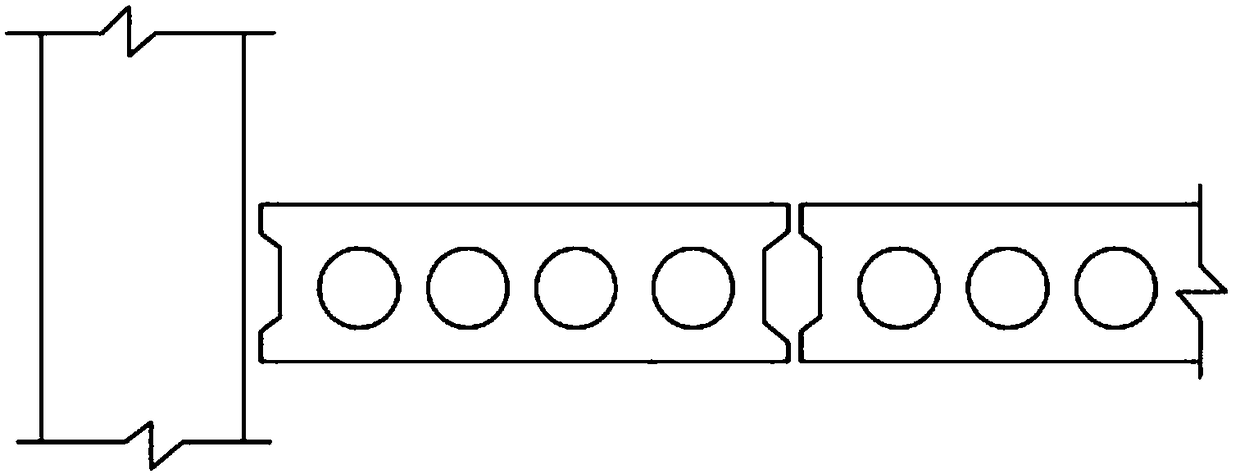

[0025] A factory prefabricated floor structure, including four foot pieces 1, four beams and rods 2, and several floor plates 3, the feet 1 play the role of connecting the beams and rods 2, and transmit the force to the concrete foundation, the feet 1. The beam member 2 is assembled into a fastened rectangular frame, and the floor plate 3 is clamped. The three major components of the floor plate 3, beam member 2, and foot member 1 are integrated into one body, and the structural integrity is strong. The foot part 1 includes a central main body 4 and three receiving parts extending outward from the central main body. The bayonet socket 5 and a mortise and tenon block 7 are respectively located on the three adjacent surfaces of the central main body 4. The mortise and tenon block 7 is a wedge-shaped protruding structure, and the middle position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com