Reaction stirring device used for water treatment mechanical equipment

A stirring device and mechanical equipment technology, applied in the field of reaction stirring devices for water treatment mechanical equipment, can solve the problems of inability to stir and mix, high manual labor intensity, low mixing efficiency, etc., achieve diversified stirring methods, low manual labor intensity, Stirring effect is remarkable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following will make a clear and complete description of the reaction stirring device for water treatment mechanical equipment of the present invention with reference to the accompanying drawings.

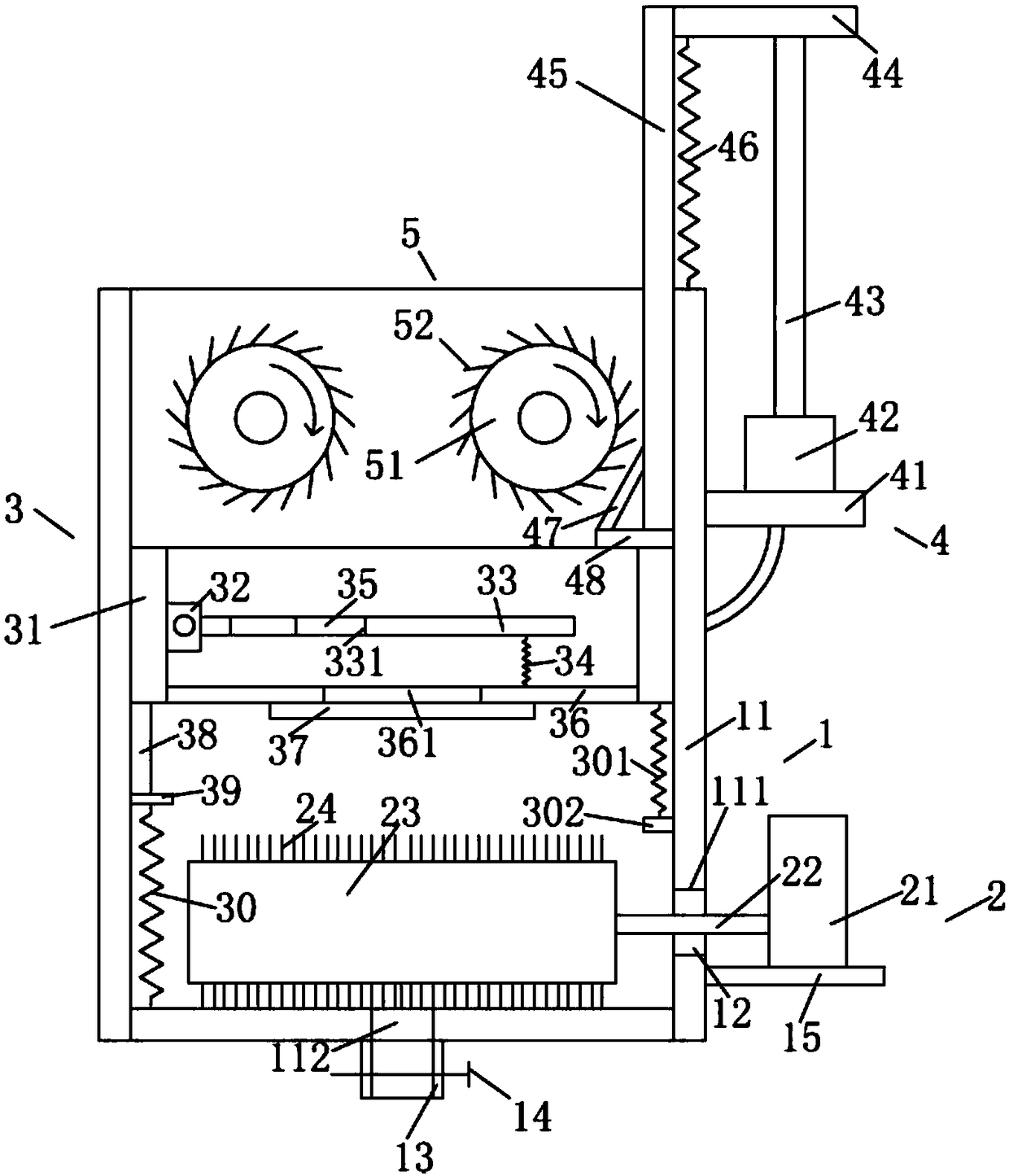

[0017] like figure 1 As shown, the reaction stirring device for water treatment machinery equipment of the present invention comprises a frame device 1, a motor device 2 arranged on the frame device 1, a first stirring device 3 accommodated in the frame device 1, and a The electric cylinder device 4 above the motor device 2 and the second stirring device 5 arranged above the first stirring device 3 .

[0018] like figure 1 As shown, the frame device 1 includes a frame body 11 , a sealing block 12 arranged on the frame body 11 , a discharge pipe 13 arranged at the lower end of the frame body 11 , and a valve arranged on the discharge pipe 13 . 14. The fixing plate 15 arranged on the right side of the frame body 11 . The frame body 11 is a hollow cuboid, the upper end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com