Opening sealing structure, sample vaporization unit, and gas chromatograph

A technology for sealing structures and sealing caps, which can be used in instruments, scientific instruments, measuring devices, etc., and can solve problems such as O-ring damage and O-ring deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

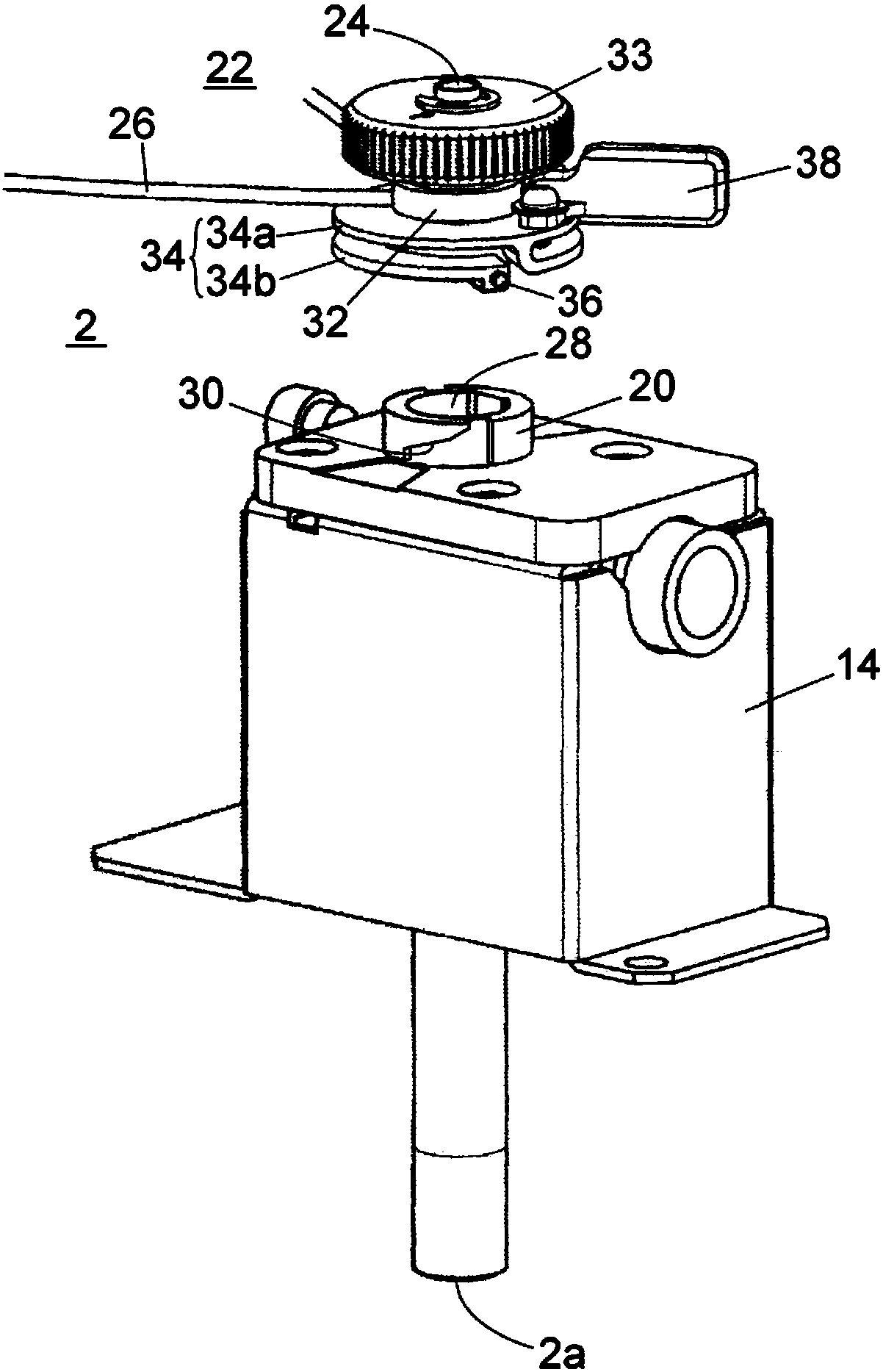

[0044] In the opening-sealing structure and the sample vaporization unit of the present invention, the stepped portion has two or more sections in which the inclination angles of the side surfaces are different from each other, and the inclination angles of the sections are preferably the following angles: In each interval, the maximum value of the force acting on the cap body fixing part in the rotation direction of the cap body fixing part is substantially the same. In this way, the operating force when turning the cap body fixing member can be made more uniform, so that the user can obtain a better operating feeling when attaching and detaching the sealing cap.

[0045] A locking portion that engages with the protrusion and stops the protrusion at that position may be provided at a position closest to the base end on the side surface of the stepped portion. In this way, it is possible to restrain the retraction of the pin rod and prevent the natural loosening of the sealing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com