spindle drive

A driver and spindle technology, which is applied in the field of door cover assemblies of motor vehicles, can solve the problems of expensive structure and cost, and achieve the effect of high braking torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

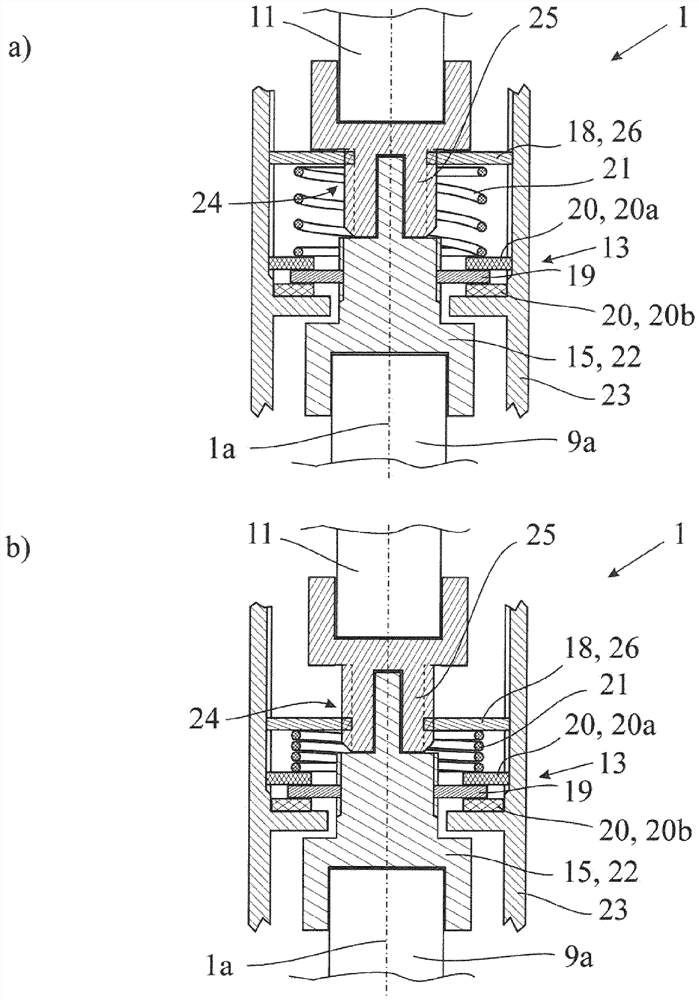

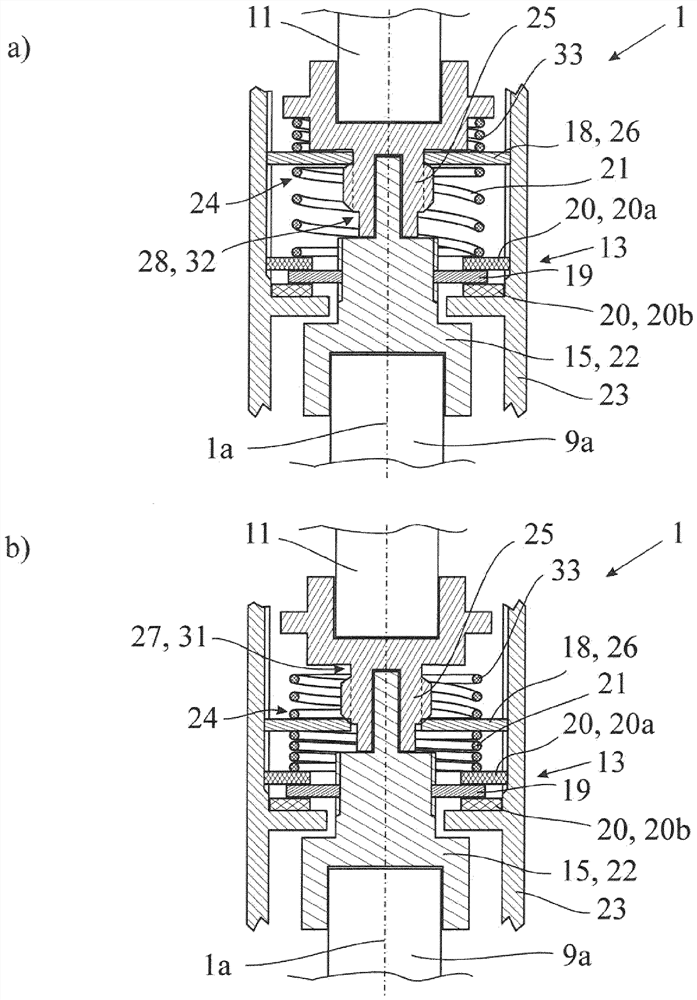

Embodiment Construction

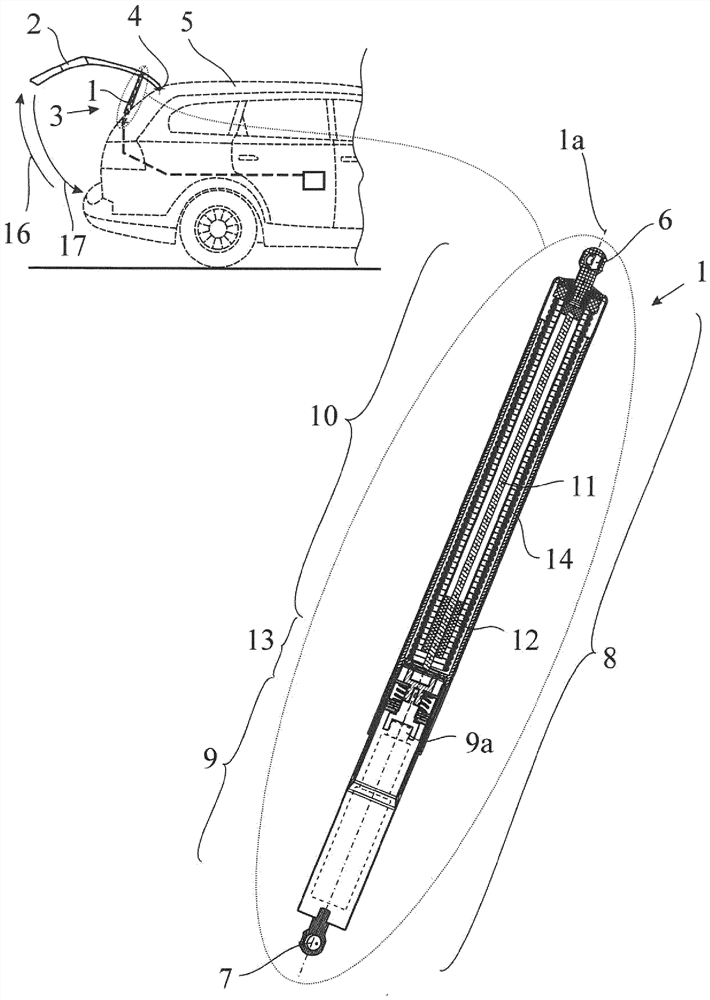

[0029] The spindle drive 1 shown in the drawing is used for the motorized adjustment of a door flap 2 of a motor vehicle, which is designed here as a tailgate. See above for a broad explanation of the concept "door cover".

[0030] In a manner conventional per se, the door cover 2 serves to close the door cover opening 3 . Here, the spindle drive 1 is arranged laterally to the door opening 3 , here and preferably in a drainage channel 4 lateral to the door opening 3 . figure 1 Although only a single spindle drive 1 is shown. However, here and preferably it is provided that the spindle drives 1 are respectively arranged on both sides of the door opening 3 . The two spindle drives 1 are substantially identical in structure.

[0031] from according to figure 1 It can be seen from the illustration that the spindle drive 1 shown there is hinged at one end to the body 5 of the motor vehicle and at the other end to the door cover 2 .

[0032] The spindle drive 1 can be adjusted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com