Ring-block friction wear testing machine

A technology of friction and wear test and friction pair, which is applied in the direction of testing wear resistance, measuring devices, instruments, etc., can solve the problems of inaccurate simulation, single friction form, and inability to realize accurate measurement of friction force, so as to ensure basic stability and improve The effect of cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution of the present invention will be further described through specific implementation manners below in conjunction with the accompanying drawings.

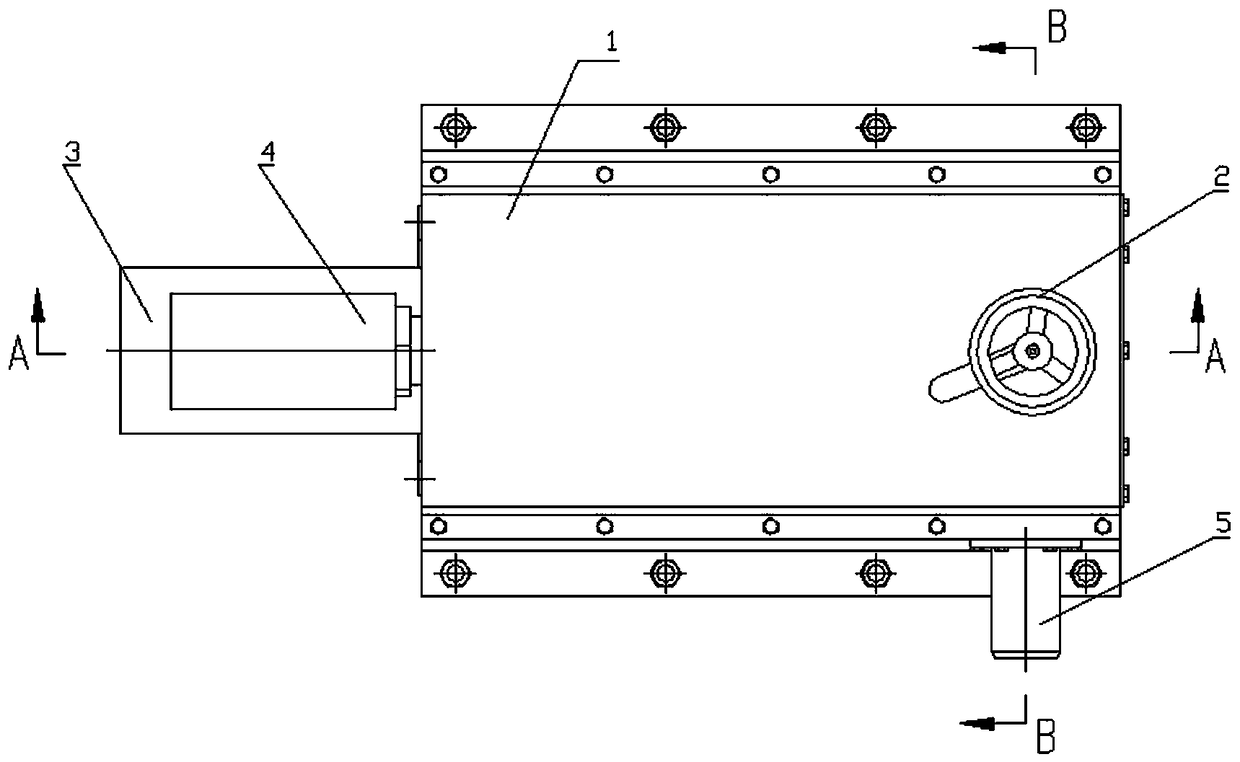

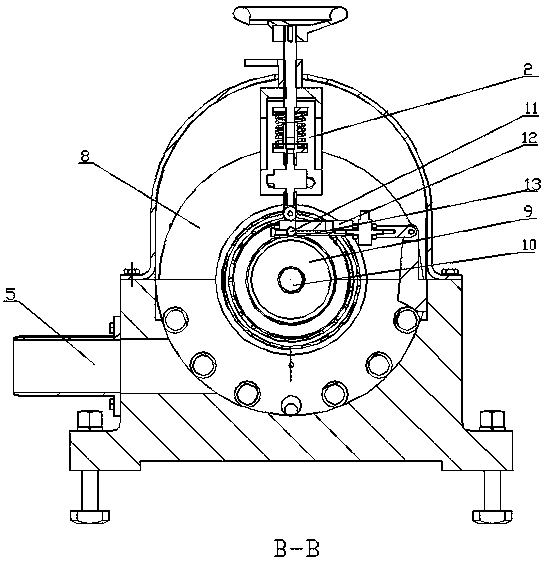

[0028] As shown in the figure, a ring-block friction and wear testing machine includes a body 1 of the testing machine, a power drive device, a main shaft 7, a ring-block friction pair, a force measuring device 12 and a radial loading device 2, and the ring-block friction The pair is located at the end of the main shaft 7 and consists of a test ring 13 and a test block 11. The hollow part at the end of the main shaft 7 is provided with a tapered threaded hole, and the tapered shaft 9 used to install the test ring 13 is installed in the tapered threaded hole at the end of the main shaft 7. , and locked by the locking screw 10, the test ring 13 is installed on the cone shaft 9, and the test ring 13 is fixed on the cone shaft 9 by the lock nut matched with the end of the cone shaft 9; the force measurement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com