Fire cover for burner of gas stove, gas stove and burner of gas stove

A technology for burners and gas stoves, applied in the field of gas stoves, can solve the problems of low thermal efficiency, inability to meet combustion requirements, insufficient gas combustion, etc., and achieve the effect of stable combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

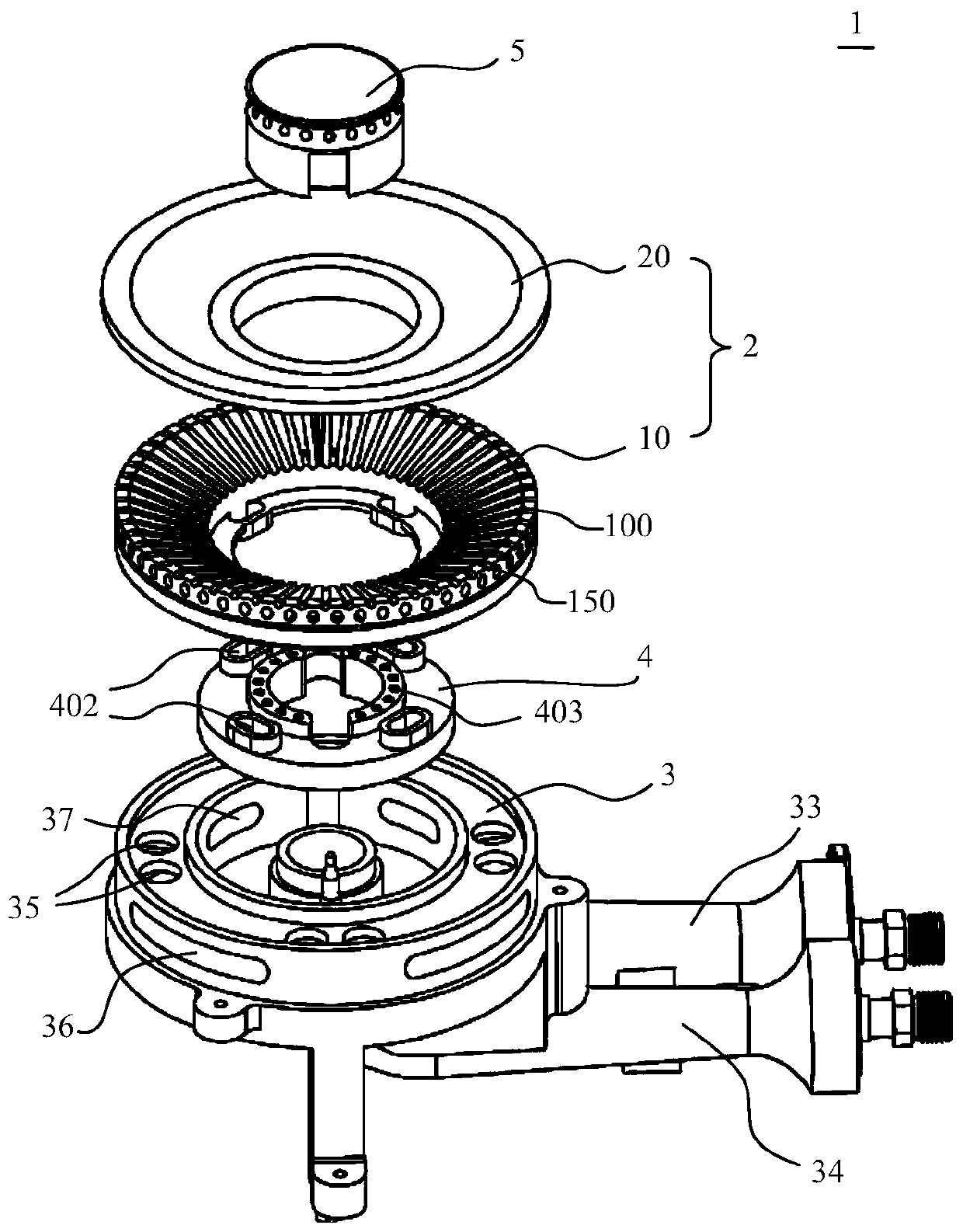

[0037] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments.

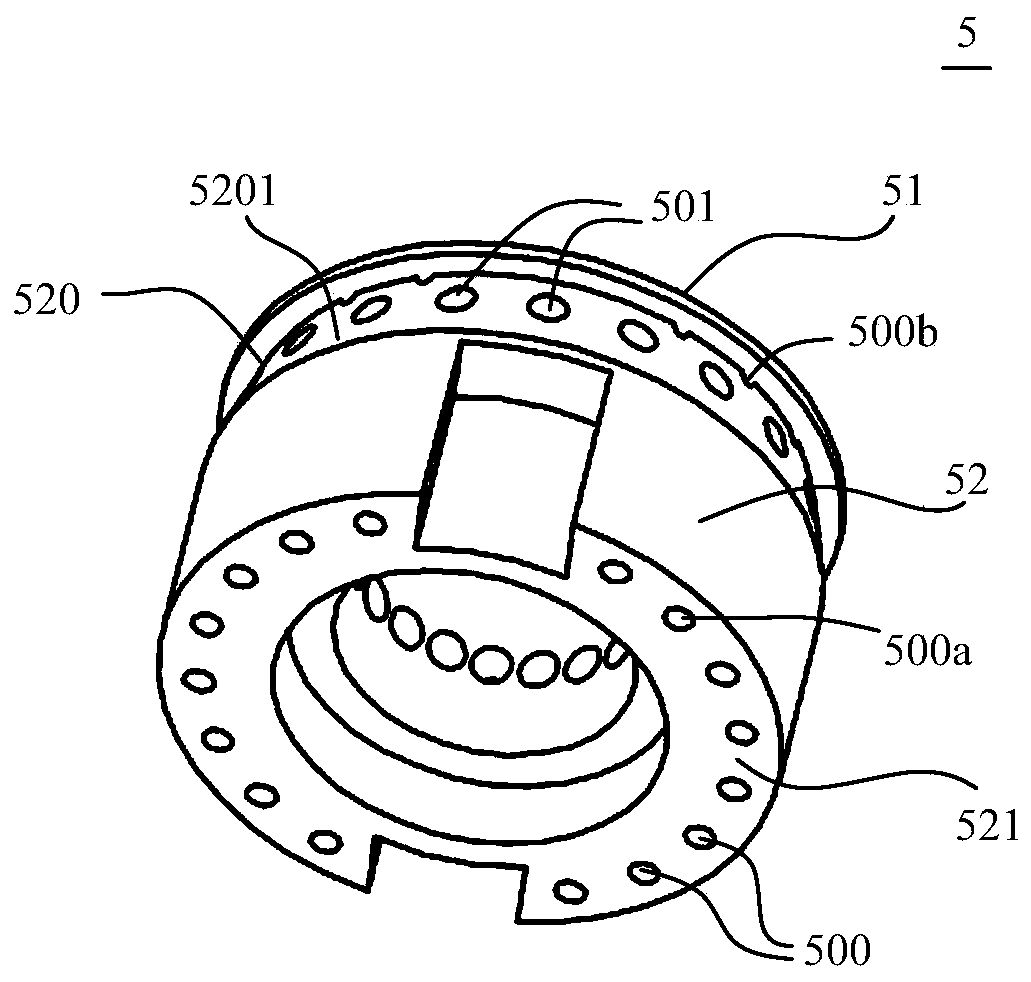

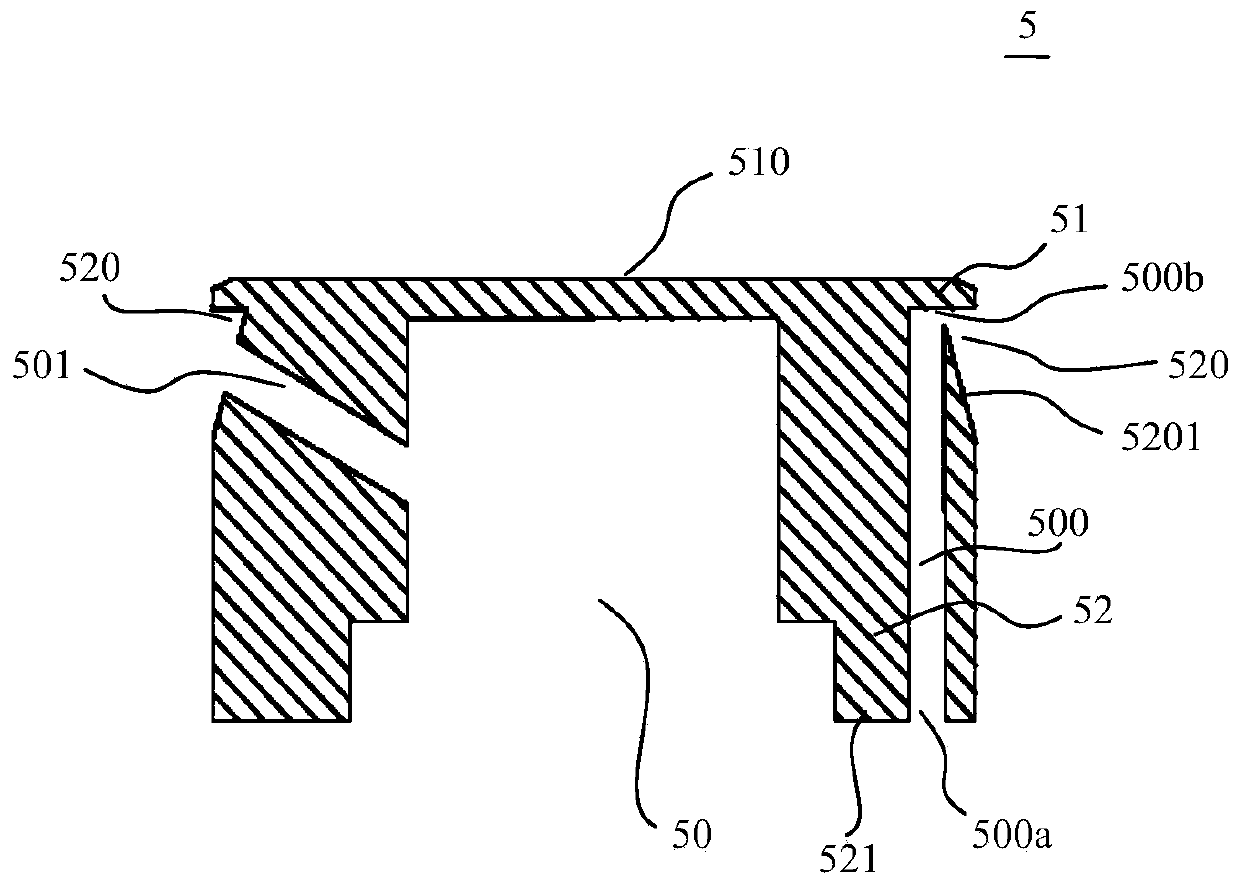

[0038]Introduce a kind of fire cover that is used for the burner of gas stove first here, as figure 1 and figure 2 shown, where figure 1 It is a perspective view of a fire cover according to an embodiment of the present invention; figure 2 It is a cross-sectional view of a fire cover according to an embodiment of the present invention. The fire cover 5 includes a cover body portion 51 and a surrounding wall body portion 52 , and the cover body portion 51 and the wall body portion 52 are integrally formed. The wall portion 52 defines a recessed portion 50 for containing gas, and the wall portion 52 is provided with a plurality of fire holes 501 communicating with the recessed portion 50 . A plurality of fire outlet holes 501 are distributed along the circumferent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com