Frame body structure of door and window system

A frame structure, door and window technology, applied in the installation of window glass, windows/doors, building components, etc., can solve the problems of multiple types of materials, high design and production costs, inconvenient installation, etc., and achieve good aesthetics and save design Production cost, easy installation and labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

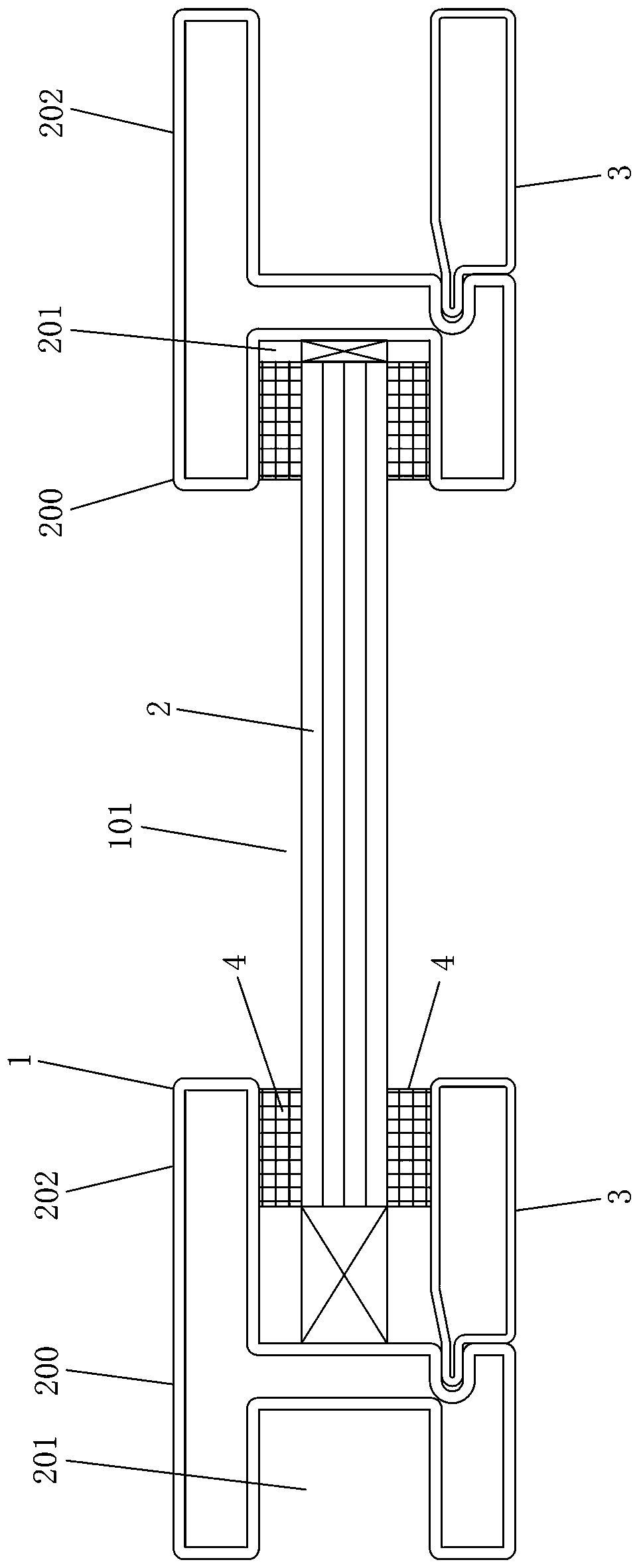

[0025] Such as figure 1 As shown, the frame structure of the door and window system of this embodiment includes a skeleton 1, the skeleton 1 has a fixed frame 101, and the glass plate 2 is installed in the fixed frame 101, and the skeleton 1 is formed by connecting load-bearing beams 200, and the load-bearing beams 200 One side of the bearing beam 200 is provided with a concave card slot 201, and the other side of the load-bearing beam 200 is provided with a rib 202. In the load-bearing beam 200 around each fixed frame 101, the concave card slot 201 of at least one load-bearing beam 200 is used to fix the glass plate 2 , and the ribs 202 of the remaining load-bearing beams 200 are clamped and fixed to the glass plate 2 in cooperation with the limiting member 3 connected to the load-bearing beam 200 . All the above-mentioned load-bearing beams 200 are profiles with the same structure, shape and size, and all the limiting members 3 are members with the same structure, shape and ...

Embodiment 2

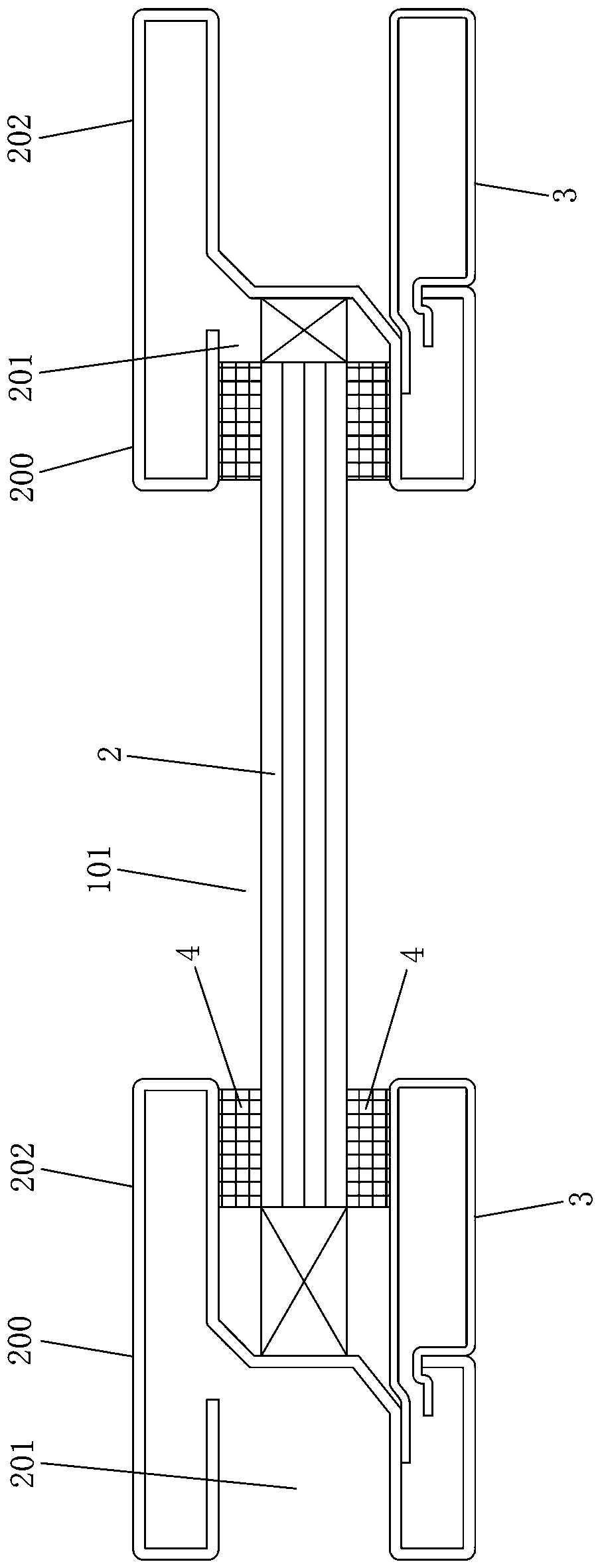

[0031] The frame structure of the door and window system of this embodiment is basically the same as that of Embodiment 1, the main difference is that, as figure 2 As shown, in this embodiment, the load-bearing beam 200 is an open profile bent from a plate, which is easy to manufacture and low in manufacturing cost.

[0032] In this embodiment, one end of the plate of the load-bearing beam 200 in the form of an open profile is located on one side of the concave groove 201 , and the other end is located on one side of the rib 202 .

Embodiment 3

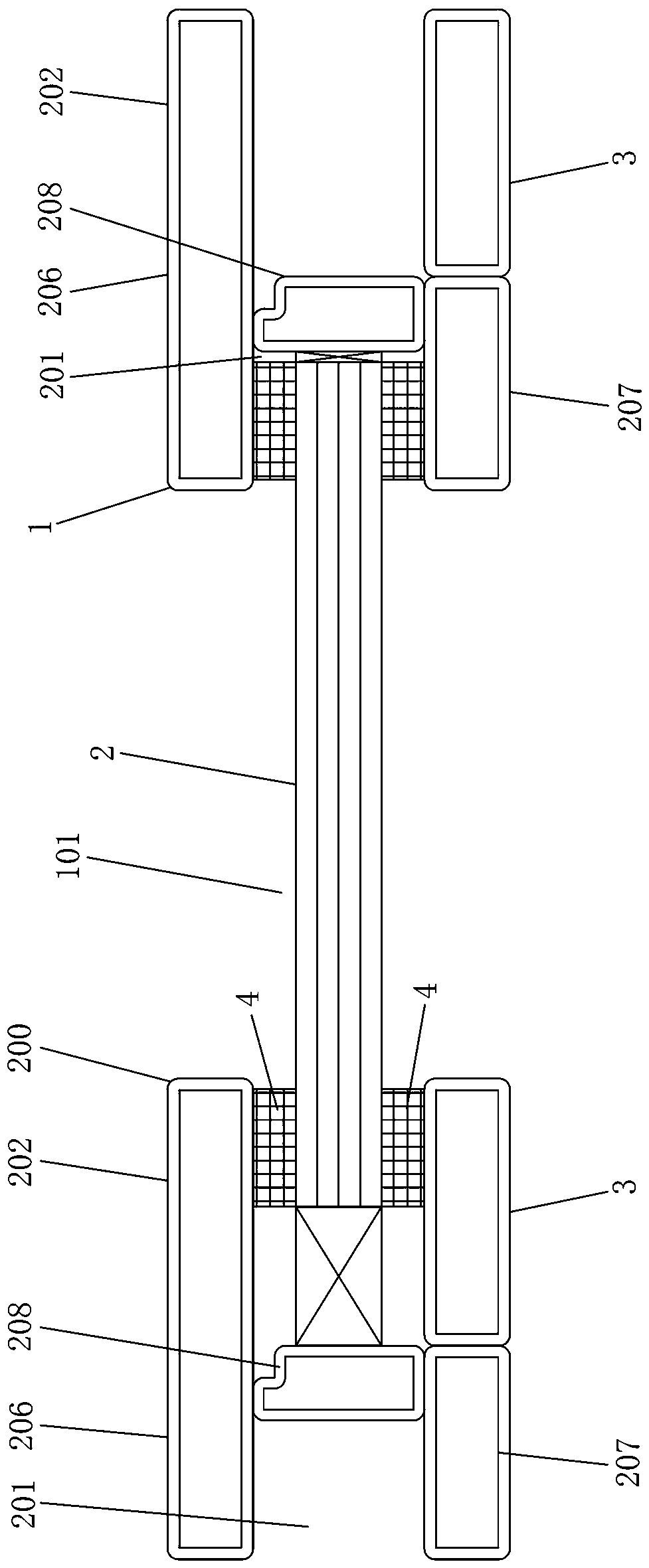

[0034] The frame structure of the door and window system of this embodiment is basically the same as that of Embodiment 1, the main difference is that, as image 3 As shown, in this embodiment, the load-bearing beam 200 includes a first side stopper 206, a second side stopper 207, and an intermediate connecting member 208, and the second side stopper 207 is connected to the first side stopper 206 through the intermediate connecting member 208 The middle part of the first side stopper 206, one side part of the second side stopper 207 and the intermediate connecting piece 208 encircle the concave slot 201 of the load-bearing beam 200, and the other side part of the first side stopper 206 is used as a load-bearing Rib 202 of beam 200 .

[0035] The limiting member 3 of this embodiment is fixed on the second side stopper 207 by means of welding.

[0036] The first side stopper 206 , the second side stopper 207 and the intermediate connecting piece 208 are all pipes, and the inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com