A papermaking pollution reduction device

A hole-slot and seat technology, applied in the field of papermaking, can solve the problems of complex composition, poor biodegradability and intractability of papermaking wastewater, and achieve the effects of facilitating maintenance and warranty, increasing usability and improving cleaning speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

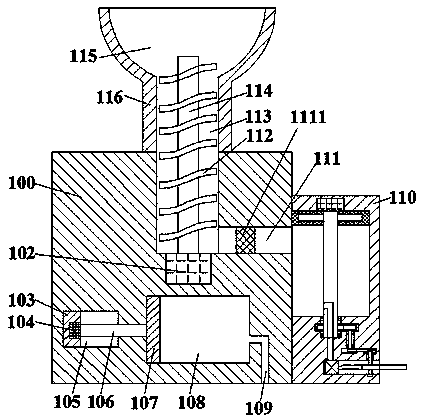

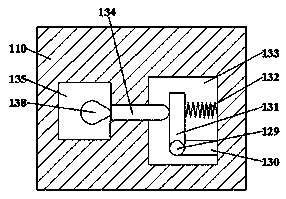

[0015] Such as Figure 1-Figure 4 As shown, a papermaking pollution emission reduction device of the present invention includes a submerged base 100, a water bucket 116 disposed on the top of the submerged base 100, and an emission reduction base disposed at the right end of the submerged base 100 110, the submersible seat 100 is provided with a first hole 113 with the port upward, and the water drawer 116 is provided with a concave cavity 115 whose bottom communicates with the top of the first hole 113, and the first hole The inner wall of the right end of the groove 113 is connected with a through cavity 111 extending to the right, and a filter plate 1111 is fixedly installed in the through cavity 111, and the upper and lower bottom of the first hole groove 113 is arranged in the submerged seat body 100. Adjusting device, the first motor 102 is embedded in the inner wall of the bottom of the first hole 113, and the top end of the first motor 102 is connected with the first r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com