Double-pore size high-efficiency desulfurization tray for desulfurization tower

A desulfurization tower and double-aperture technology, applied in the field of double-aperture high-efficiency desulfurization trays, can solve the problems of low flue gas flow rate, large resistance, and poor operating flexibility, and achieve the effect of reducing operating costs, small resistance coefficient, and good operating flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

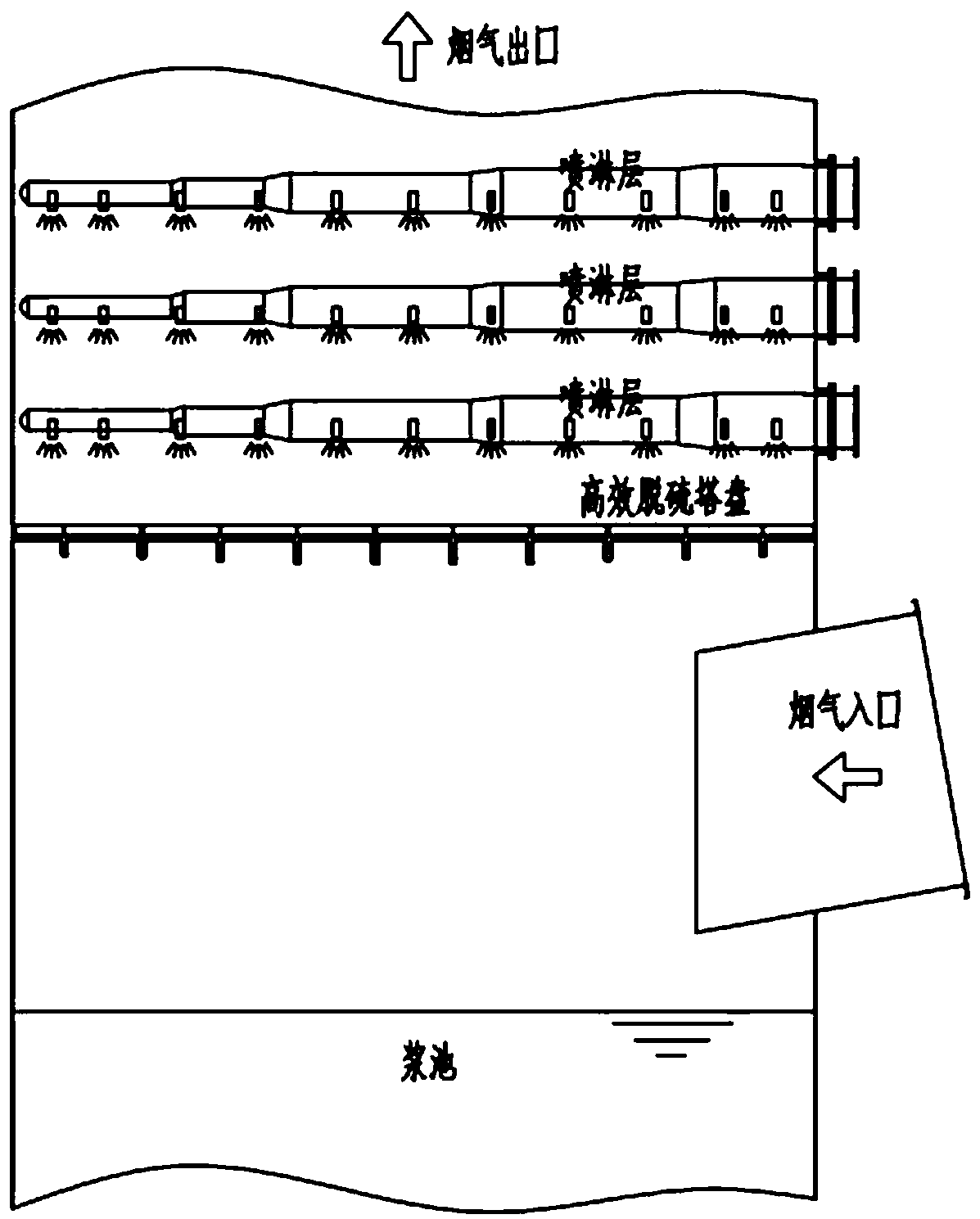

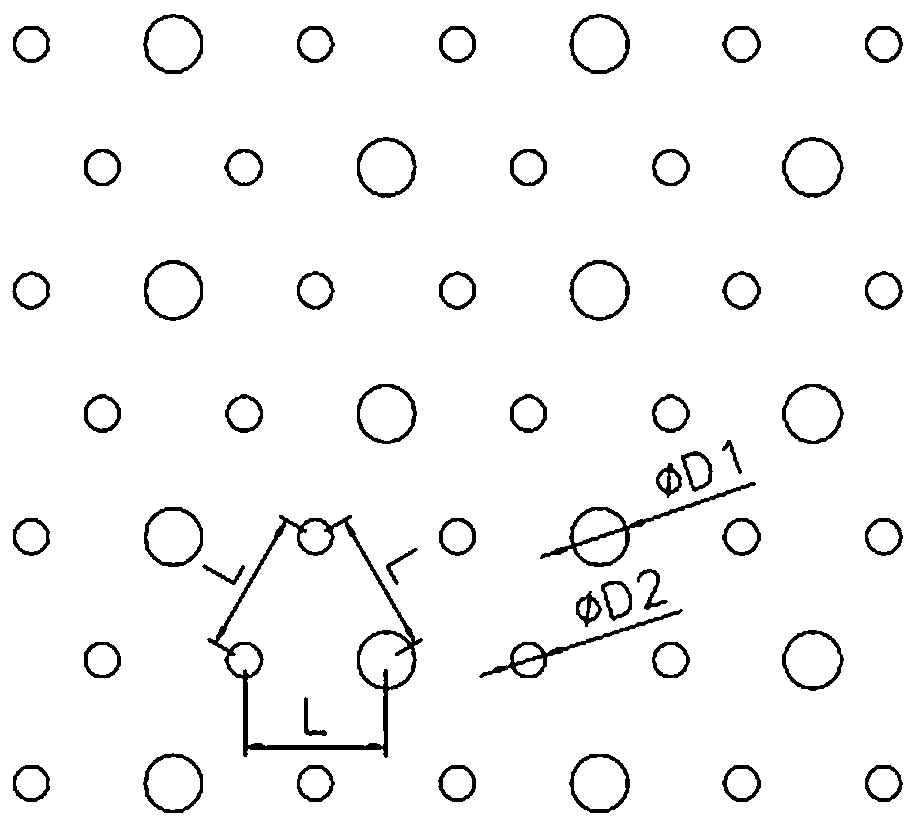

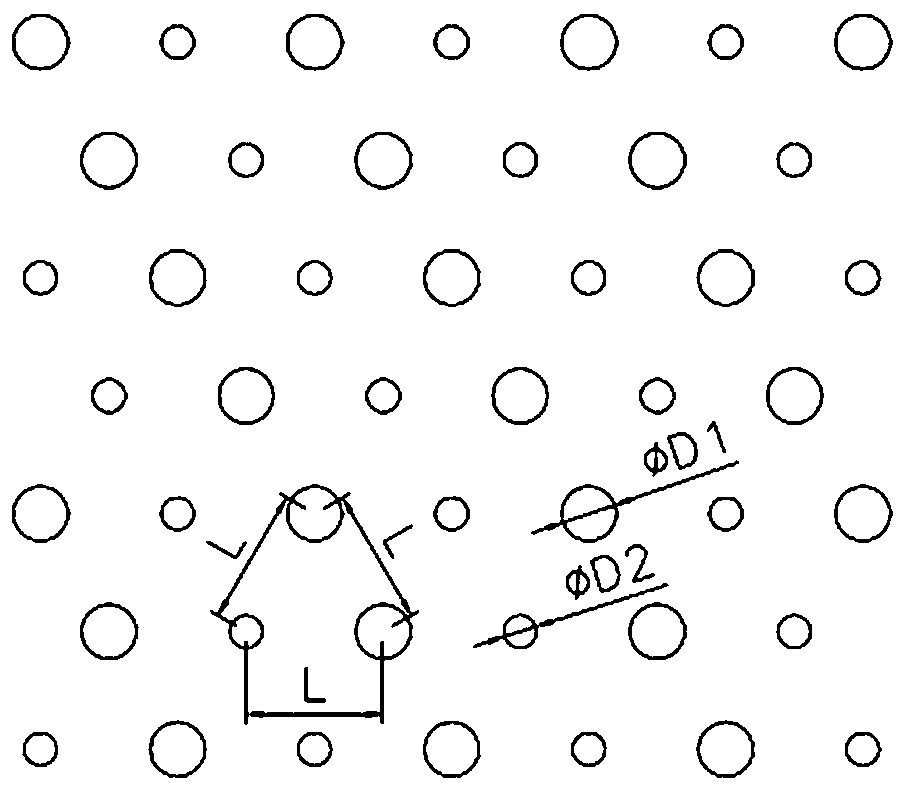

[0016] see Figure 1 to Figure 4 , the present invention is used for the double-aperture high-efficiency desulfurization tray of the desulfurization tower, which is placed between the flue gas inlet and the lowest spray layer in the desulfurization tower, and is a through-flow porous sieve plate, which is arranged in one or more layers. The surface of the desulfurization tray is evenly distributed with openings with two diameters of round hole 1 and round hole 2. The diameter of round hole 1 is D 1 35~45mm, the hole diameter D of the second round hole 2 20~30mm, and D 2 =(50%~70%)*D 1 . The hole spacing L between the openings on the desulfurization tray is determined according to the average opening ratio of the desulfurization tray, and the average opening ratio is determined by the liquid-gas ratio and desulfurization efficiency in the desulfurization tower, usually 25-50%.

[0017] see Figure 2 to Figure 4 , are the three methods of evenly distributing the openings on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com