A new type of socket

A socket, a new type of technology, applied in the direction of contact parts, etc., can solve the problems of short service life of the socket, non-conduction, loose socket plugs, etc., and achieve the effect of increased service life, less wear and reliable electrical connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

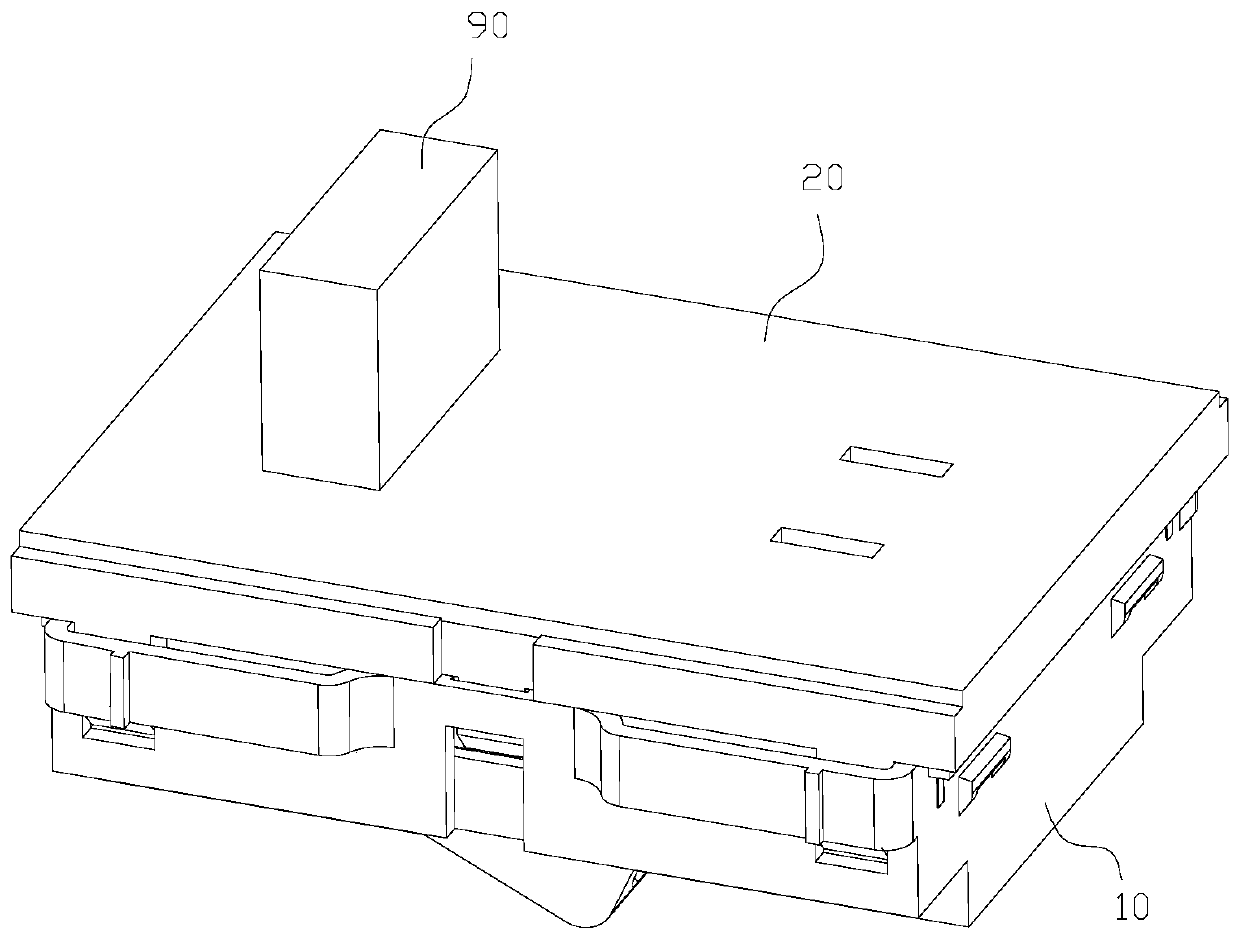

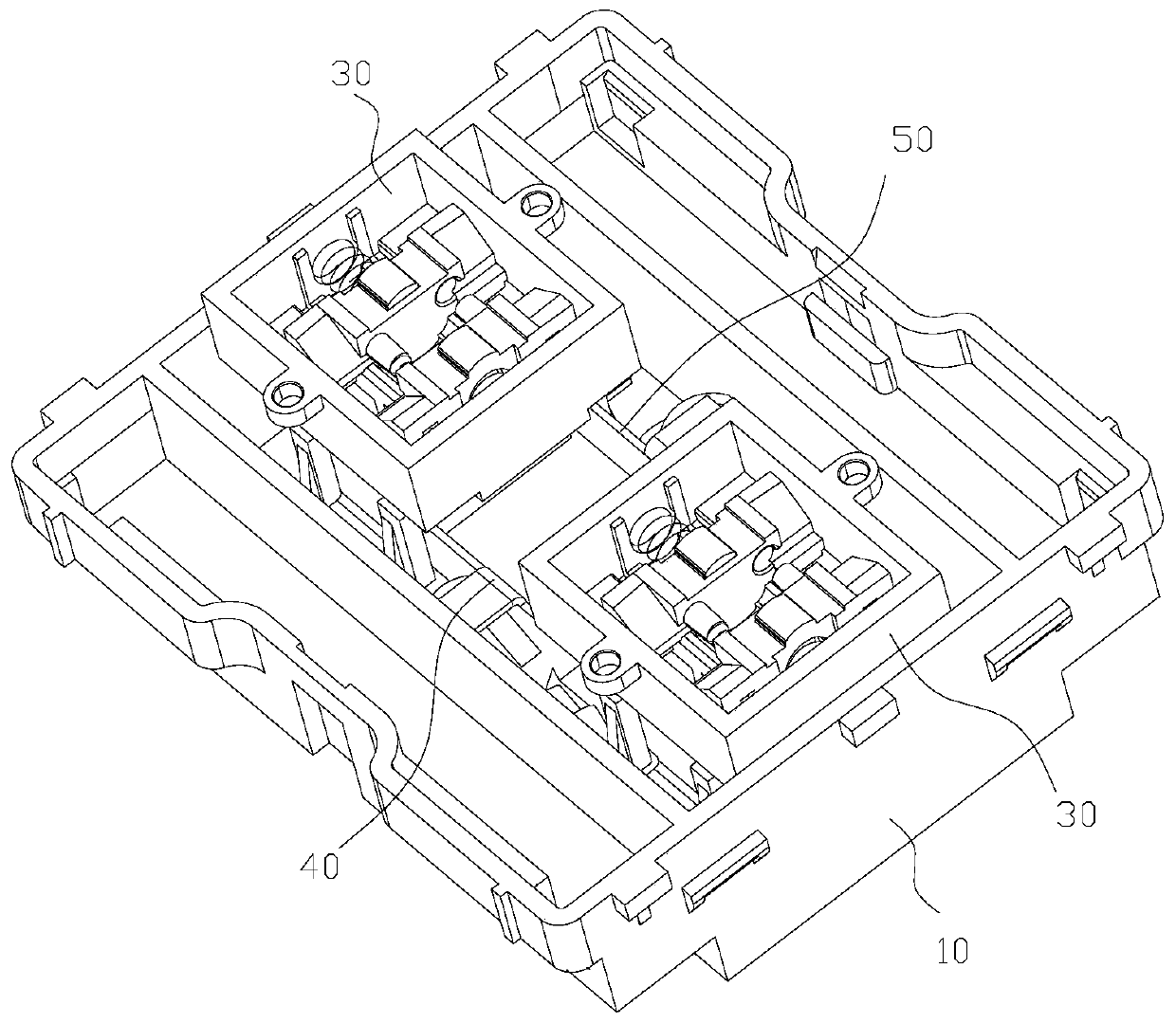

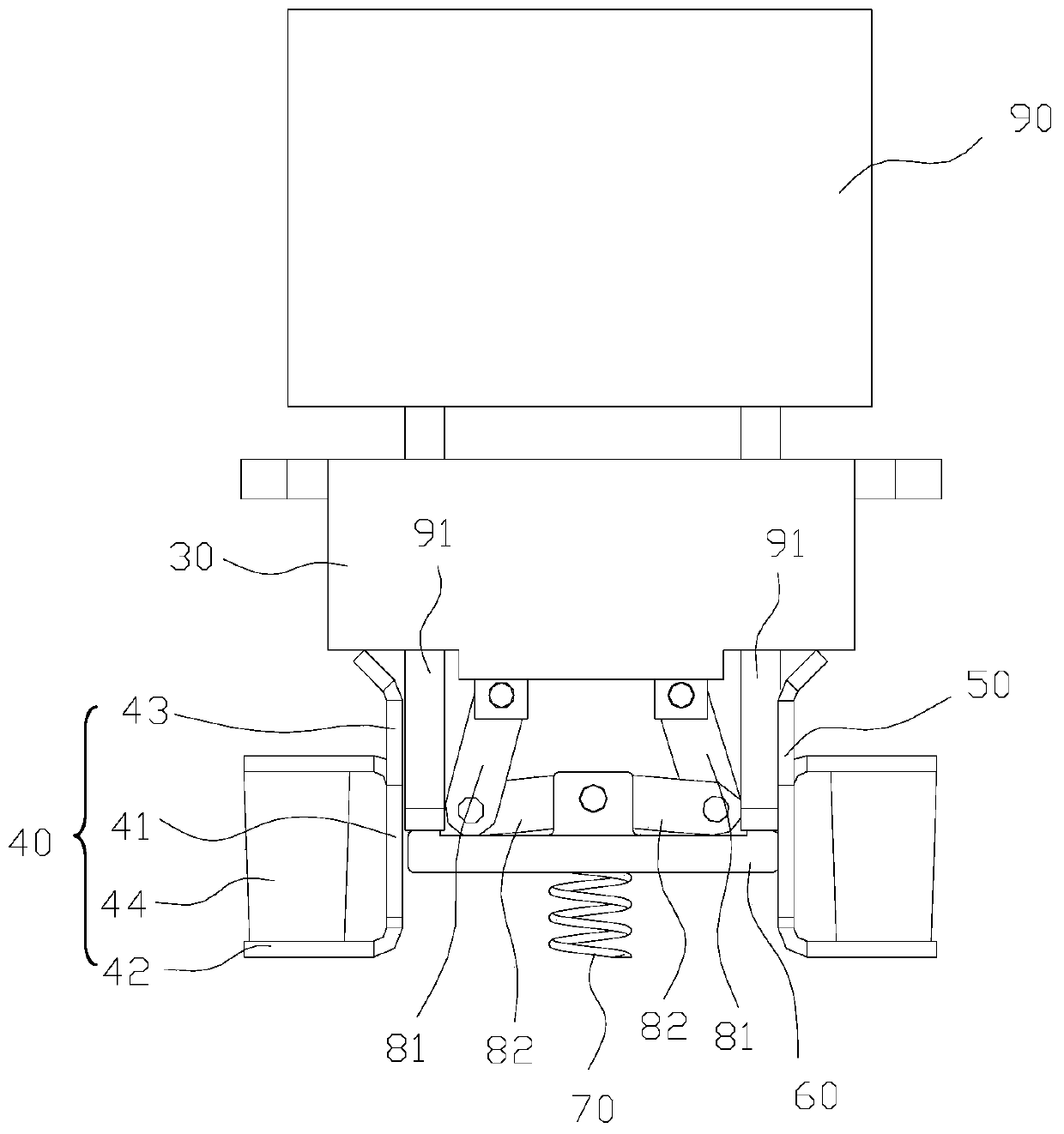

[0012] Combine below Figure 1-Figure 6 , to further describe the present invention.

[0013] A new type of socket, including a groove-shaped housing 10, the notch of the housing 10 is matched with a panel 20, and a protective door 30, a first conductive sheet 40 and a second conductive Sheet 50, the first conductive sheet 40 and the second conductive sheet 50 are arranged in parallel and at intervals and both are vertically fixed on the bottom of the groove in the housing 10, and a supporting seat is arranged between the first conductive sheet 40 and the second conductive sheet 50 60, the support seat 60 is elastically fixed above the groove bottom in the casing 10 through the spring 70 arranged vertically, and two linkage mechanisms are arranged on the support base 60, the linkage mechanisms include an upper link 81 and a lower link 82, and the upper link 81 and the lower link 82 One end of the connecting rod 81 is hingedly fixed on the bottom surface of the protective door...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com