Sanding simulation measuring device and method for marine natural gas hydrate reservoir mining process

A technology of mining process and measuring device, which is applied in the fields of mining fluid, measurement, and earth-moving drilling, etc., can solve problems such as geological disasters, lack of good cementation, blockage of mining wells, etc., and achieve effective mining, reliable theoretical and technical support. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. However, it should be understood that the accompanying drawings are provided only for better understanding of the present invention, and they should not be construed as limiting the present invention.

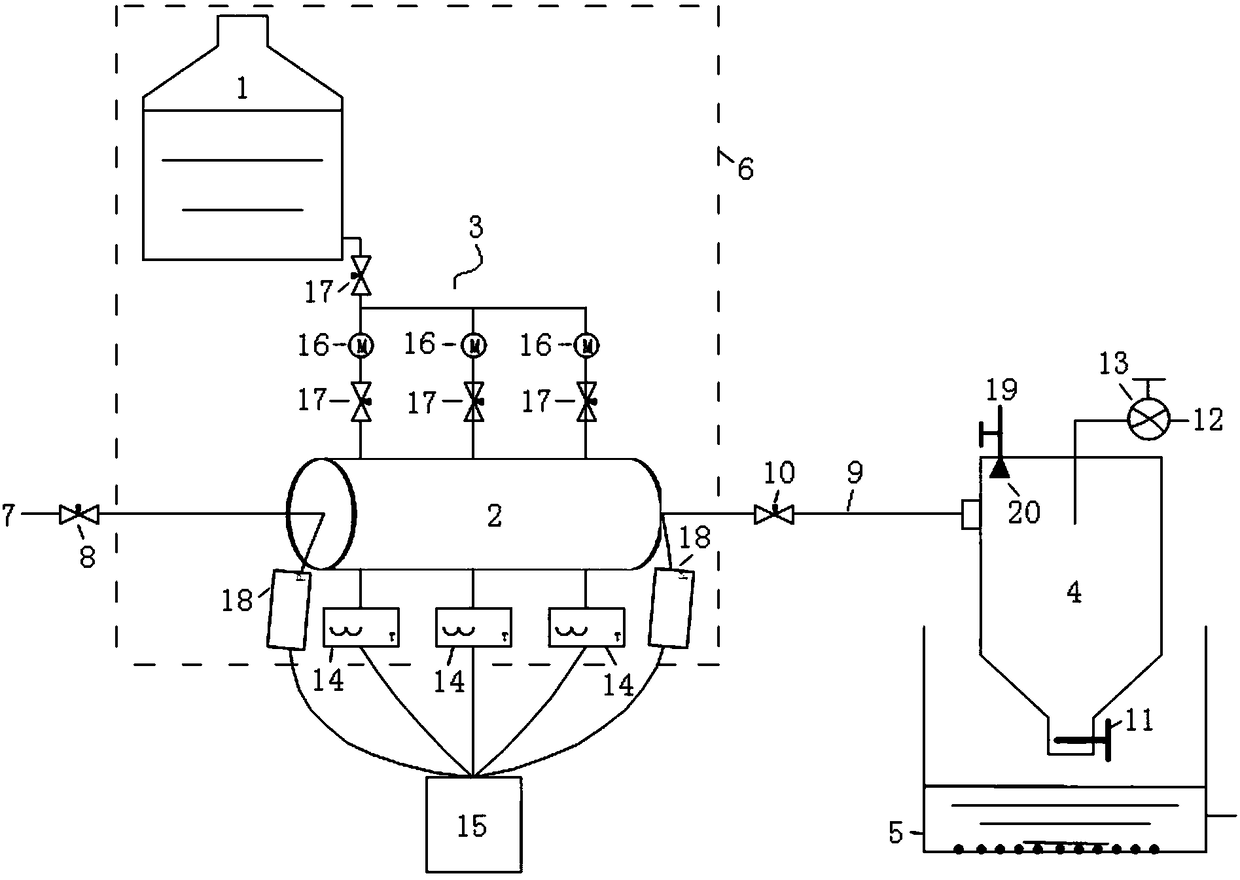

[0030] figure 1 The simulation measurement device for sand production in the exploitation process of marine natural gas hydrate reservoirs according to the present invention is shown. The simulation measurement device includes a high-pressure seawater storage tank 1, a high-pressure sand filling pipe 2, a seawater intrusion simulation pipeline 3, and a gas-water-sand separation device 4. Sand / water receiver 5 and high and low temperature test chamber 6.

[0031] The high-pressure seawater storage tank 1 is placed in the high and low temperature test chamber 6, and the high-pressure seawater storage tank 1 is pre-stored with high-pressure seawater, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com