Prefabricated lattice beam and construction method thereof

A construction method and technology of lattice beams, applied in basic structure engineering, excavation, construction, etc., can solve the problems of difficult construction, long concrete pouring time, and long construction period, so as to achieve reasonable utilization and easy quality control , The effect of low construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

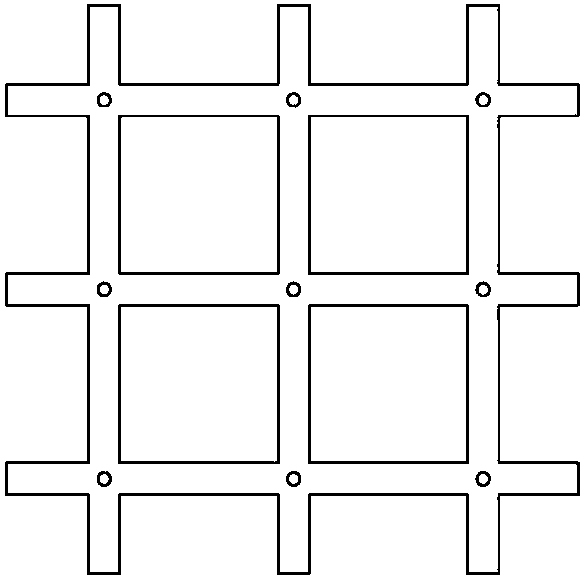

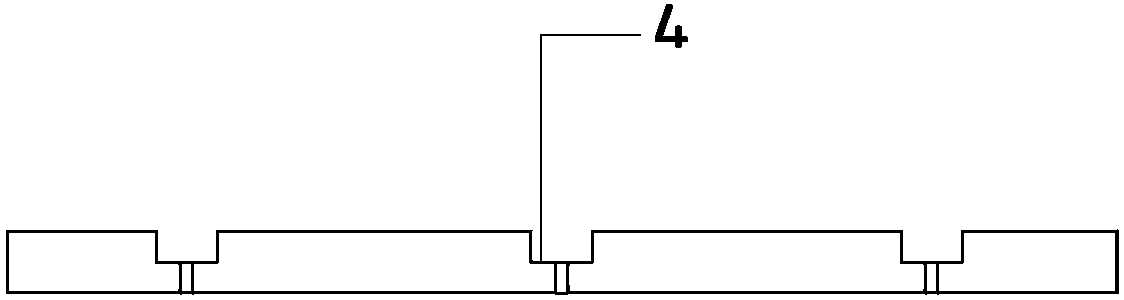

[0042] Embodiment 1, a prefabricated lattice beam provided by the present invention, the prefabricated lattice beam includes several unit lattice beams, and the unit lattice beam is composed of beams 1 and longitudinal beams 3 intersecting in the same position to form a grid-like beam body, and the unit The upper and lower surfaces of lattice beams are flush; see figure 1 shown. like Figure 3a , 3b As shown in and 3c, the beam body of the beam 1 is provided with first grooves 2 at intervals, the first groove 2 has three and its depth is equal to half of the height of the beam 1; the two ends of the beam 1 are respectively centered with the third groove 5 and The protrusion 6 is adapted to the third groove 5 and the protrusion 6 , and the depth of the third groove 5 is the same as the length of the protrusion 6 .

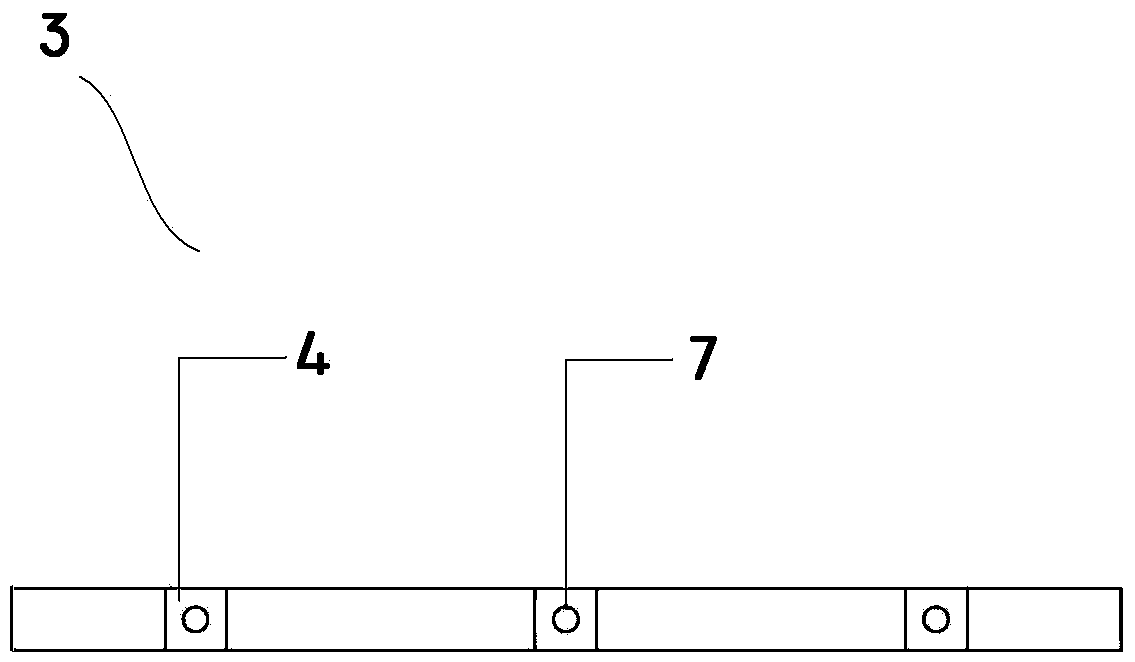

[0043] like Figure 2a , 2b As shown in , 2c, the longitudinal beam 3 is a concrete member with steel bars 8, and the cross section is rectangular. Groove 4; ...

Embodiment 2

[0055] Example 2, such as Figure 5a , 5b, 5c, a prefabricated lattice beam, the same as embodiment 1, the difference is: the cross beam 1 is pre-embedded with steel bars 8. The steel bar 8 can be connected by methods such as binding lap joint or welding or mechanical sleeve.

[0056] see also Image 6 , the unit cell beams are connected by steel bars 8 arranged in the beam 1; concrete is also poured at the joints of the steel bars 8.

[0057] The specific construction method is as follows:

[0058] Step 1, according to the design drawings, the beam 1 and the longitudinal beam 3 are prefabricated in the prefabrication factory;

[0059] Step 2, transporting the prefabricated beam 1 and longitudinal beam 3 to the construction site;

[0060] Step 3, stacking the prefabricated beams 1 and longitudinal beams 3 in the yard;

[0061] Step 4, according to the requirements of the construction drawing, perform measurement and positioning, level the slope, and construct anchor rods...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com