Carrier band material disc replacing intelligent device

A technology of intelligent equipment and trays, which is applied in thin material processing, transportation and packaging, and winding strips, etc., can solve the problems of inability to monitor the operation status of products and equipment in real time, and achieve manpower saving, cost reduction, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

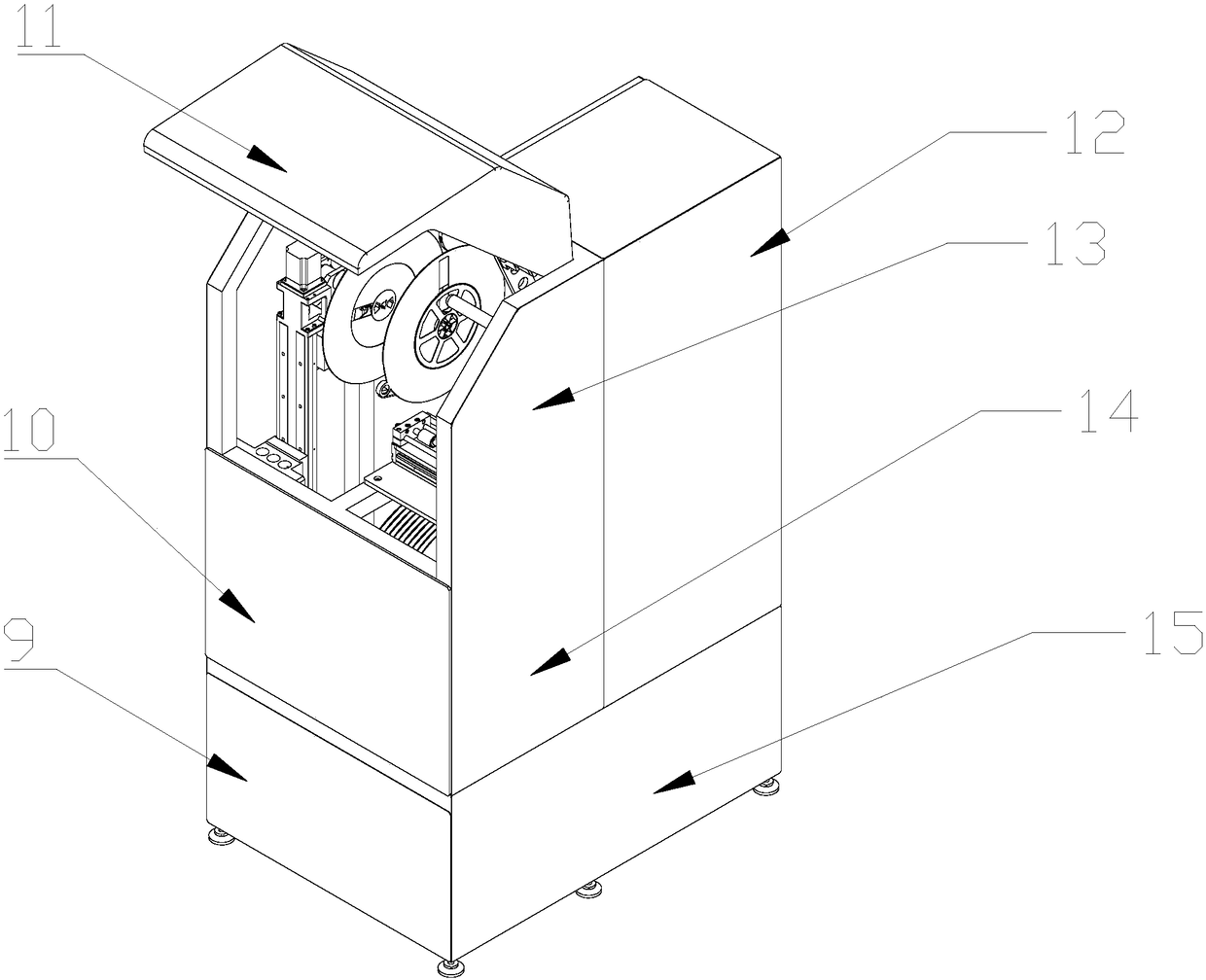

[0018] as attached figure 1 , 2 As shown, the present invention provides an intelligent equipment for replacing carrier tape reels, which is characterized in that the intelligent equipment for replacing carrier tape reels includes a reel sampling manipulator 1, a sealing tape system 2, a sealing tape conveying track 3, and a quality monitoring camera 4. Material belt counter 5, external air source interface 6, power interface 7, material belt feeding buffer zone 8, control integration box 9, fully loaded material tray removal door 10, empty material tray front door 11, material tray replacement robot shell 12 , an empty tray storage mechanism 13, a fully loaded tray mechanism 14, and a tray replacement robot host 15; the tray replacement robot shell 12 is provided with a tray sampling manipulator 1, and the lower end of the tray sampling manipulator 1 is provided with a belt conveyor track 3 , the outer side of the sealing tape conveying track 3 is provided with a material fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com