Rotary preserved szechuan pickle filling equipment

A filling equipment and rotary technology, applied in the field of rotary mustard filling equipment, can solve the problems of high labor intensity, poor sanitation, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

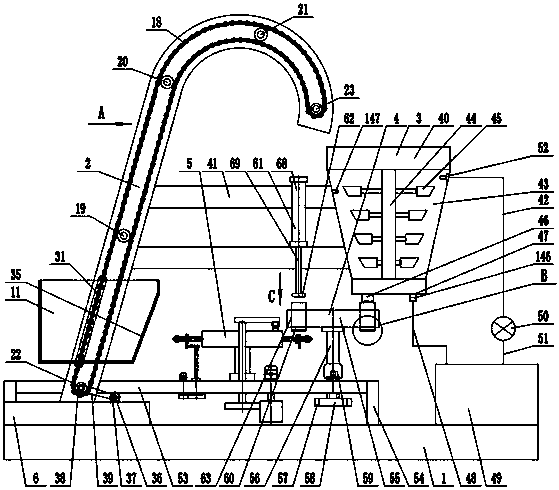

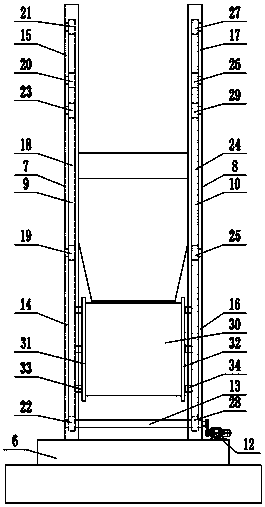

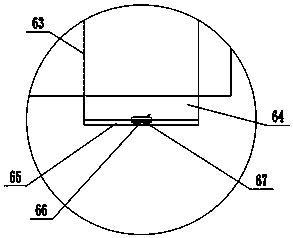

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 with Figure 9As shown, a rotary mustard vegetable filling equipment includes a support base 1, a transport and dump mechanism device 2, a stirring and seasoning device 3, an automatic material distribution device 4, and a rotary filling device 5. The transport and dump mechanism device 2 includes The handling base 6, the first spoon-shaped support 7, the second spoon-shaped support 8, the first lifting assembly 9, the second lifting assembly 10, the hopper assembly 11, the driving assembly 12, and the lifting synchronous shaft 13, the handling base 6 is fixed on the support base 1, the lower end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com