Method for testing maximum wrapping layer thickness of slurry at aggregate surface in permeable concrete

A technology of permeable concrete and testing method, applied in the direction of measuring device, specific gravity measurement, analyzing materials, etc., can solve the problems of complicated operation and poor flexibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

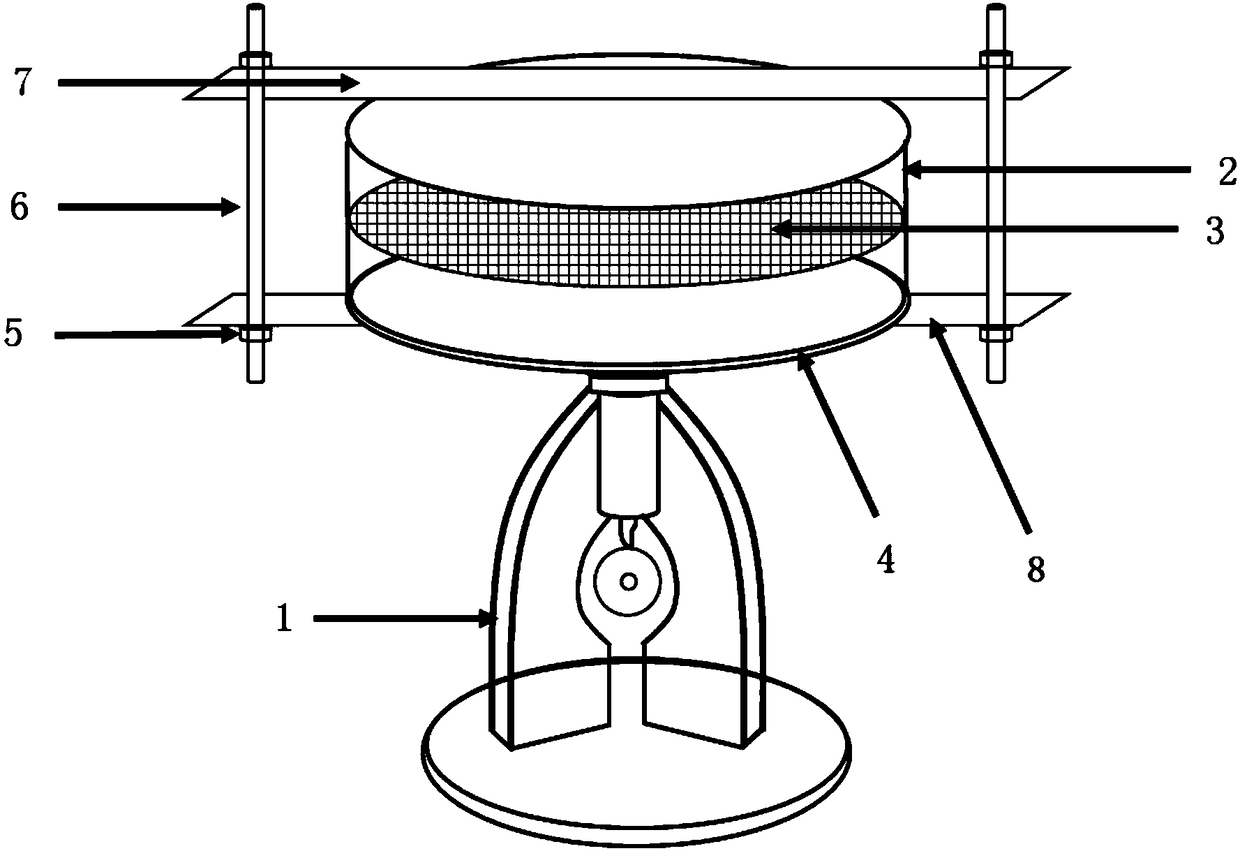

Image

Examples

Embodiment 1

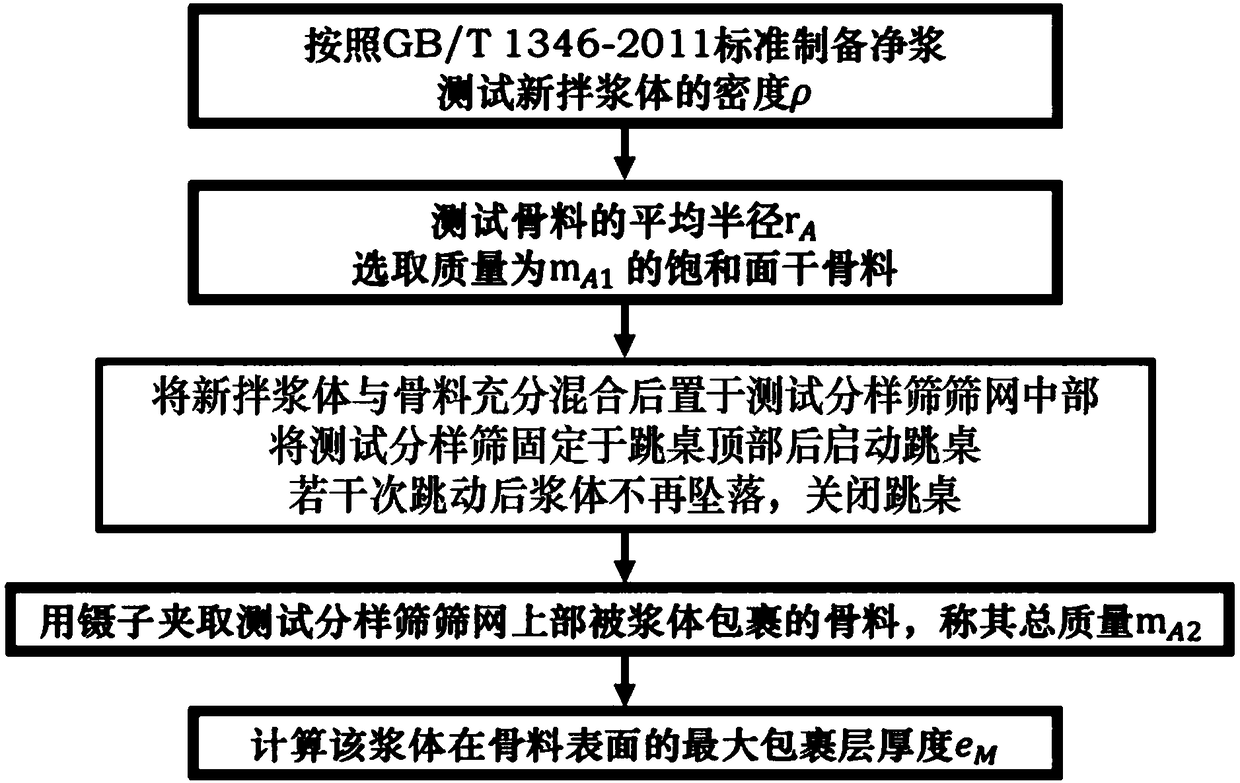

[0028] combine figure 2 As shown, the test method for the maximum coating thickness of aggregate surface slurry in pervious concrete includes the following steps:

[0029] The first step: prepare the slurry, and then test the density ρ of the slurry;

[0030] Step 2: Test the total surface area S of the aggregate;

[0031] Step 3: Test the maximum wrapping mass of aggregate surface slurry m P ;

[0032] Step 4: Calculate the maximum coating thickness of the slurry on the surface of the aggregate

[0033] Repeat the first step, the second step, the third step, and the fourth step several times; take the maximum coating layer thickness e of the aggregate surface slurry M average value.

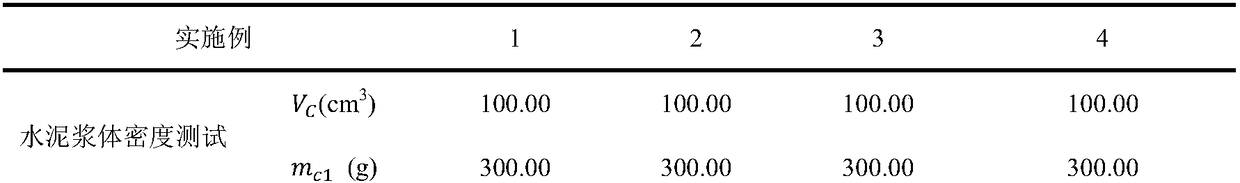

[0034] The cement slurry is the slurry, and the test procedure of the slurry density ρ is as follows: prepare the slurry according to the GB / T 1346-2011 standard, and then divide the prepared slurry into a volume of V C , the mass is m c1 In the same container, use a concrete vibrating...

Embodiment 2

[0046] Except for the following technical features, the rest of the unsubmitted technical features are the same as in Embodiment 1.

[0047] 100 parts of Portland cement, 25 parts of water, and 1 part of water reducing agent were used to prepare slurry according to the method used in Example 1, and the density of the slurry was measured to be 2.211g / cm 3 . After cleaning and drying the aggregates with a particle size of 4.75-9.5mm, randomly select 200 aggregates, and use a hydrostatic balance to test the total volume of 41.4cm 3 , the average volume of the calculated aggregate is 0.207cm 3 ; Assuming the aggregate is an ideal spherical shape, the average radius of the aggregate is calculated to be 3.67mm; the surface area of the aggregate per unit volume obtained is 8.174cm -1 (β=1) and the total surface area of the aggregate is 338.4cm 2 . Wipe the aggregate with a towel until it is saturated and surface-dry, and weigh its mass of 106.62g; weigh 91.54g of clean pulp a...

Embodiment 3

[0049] Except for the following technical features, the rest of the unsubmitted technical features are the same as in Embodiment 1.

[0050] 60 parts of Portland cement, 40 parts of superfine slag, 25 parts of water, and 1 part of water reducing agent were used to prepare slurry according to the method used in Example 1, and the density of the slurry was measured to be 2.158g / cm 3 . Washed and dried volume is 154.3cm 3 aggregate. Use a sampling sieve to classify it into two particle size ranges of 5-10mm and 10-16mm, and use a hydrostatic balance to measure its volume as 27.0cm 3 and 127.3cm 3 . Randomly take 50 aggregates of 5-10mm, and measure its volume to be 11.6cm 3 , calculate its average volume to be 0.232cm 3 ; Assuming that the aggregate is an ideal spherical shape, the average radius of the aggregate is calculated to be 3.81mm, and the surface area per unit volume of the aggregate is 7.874cm -1 (β=1); then 27.0cm 3 The total surface area of the 5 ~ 10mm agg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| total surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com