Pressure relief valve

A pressure relief valve and pressure relief technology, applied in the direction of safety valves, balance valves, valve devices, etc., can solve the problems of complicated installation, complex and cumbersome structure of pressure relief valves, and difficulty in processing and manufacturing, so as to achieve convenient installation and industrialization , the overall structure is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] 以下结合附图对本发明作进一步详细说明。

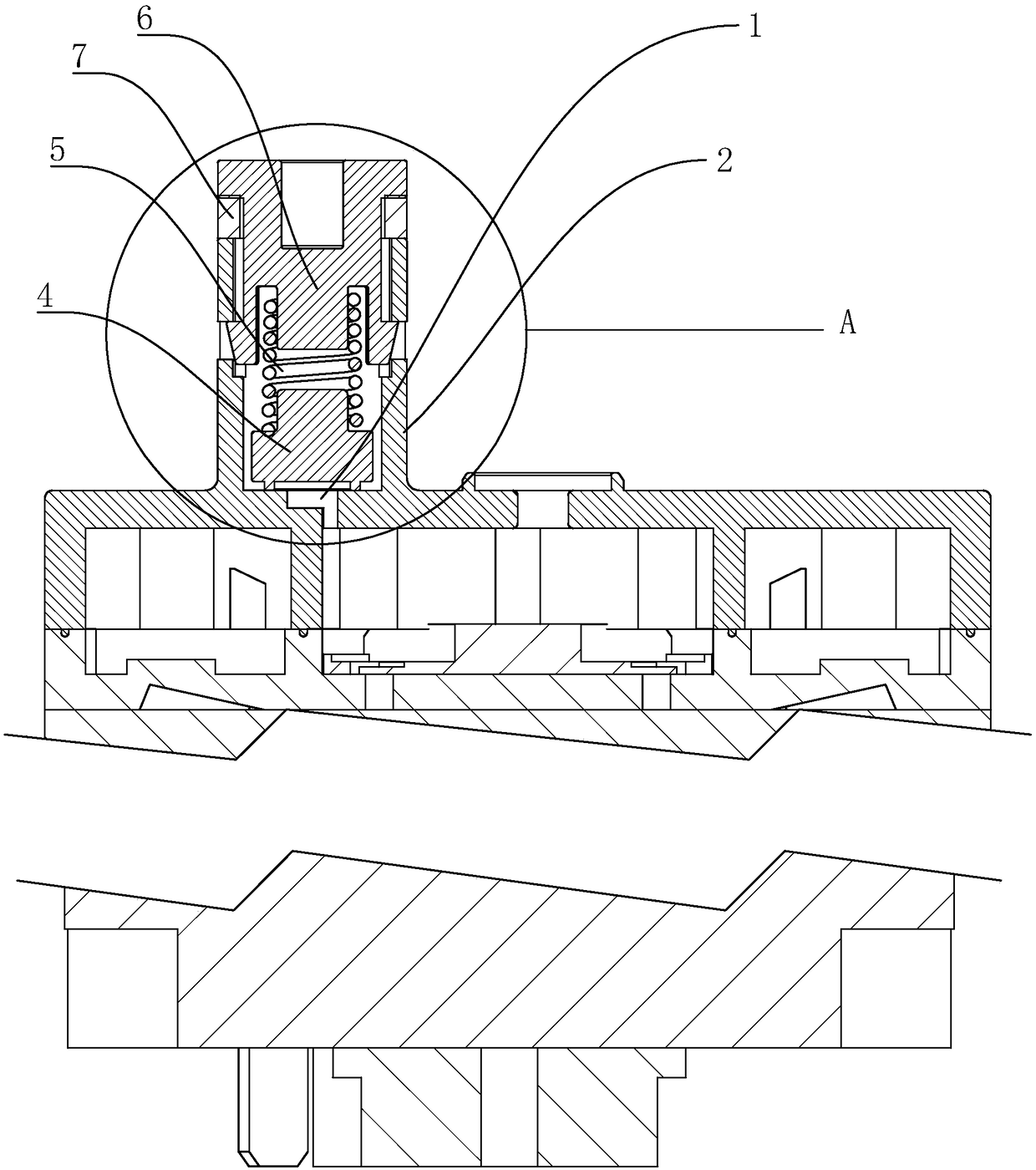

[0035] 一种泄压阀2,如 figure 1 所示,包括泄压口1和正对泄压口1设置的泄压阀2,所述泄压阀2包括泄压底座3、密封件4、弹性件5和卡接件6;泄压底座3内部设有一圆形空腔31,空腔31一端与泄压口1相连通,另一端与卡接件6卡接,卡接件6与泄压底座3之间留有一定用于出气的间隙,密封件4位于空腔31内且与泄压口1相互贴合,弹性件5位于密封件4和卡接件6之间,弹性件5抵紧密封件4和卡接件6。

[0036] 在泄压过程中,气体从泄压口1进入空腔31时,抵触到密封件4上,随着气体的增大,密封件4向上运动推动弹性件5,密封件4抵触到卡接件 6停止运动,气体从空腔31与卡扣61之间的缝隙处流出,达到泄压的目的;当气体压力减小时,密封件4在弹性件5的弹性下向下运动,封住泄压 port 1.

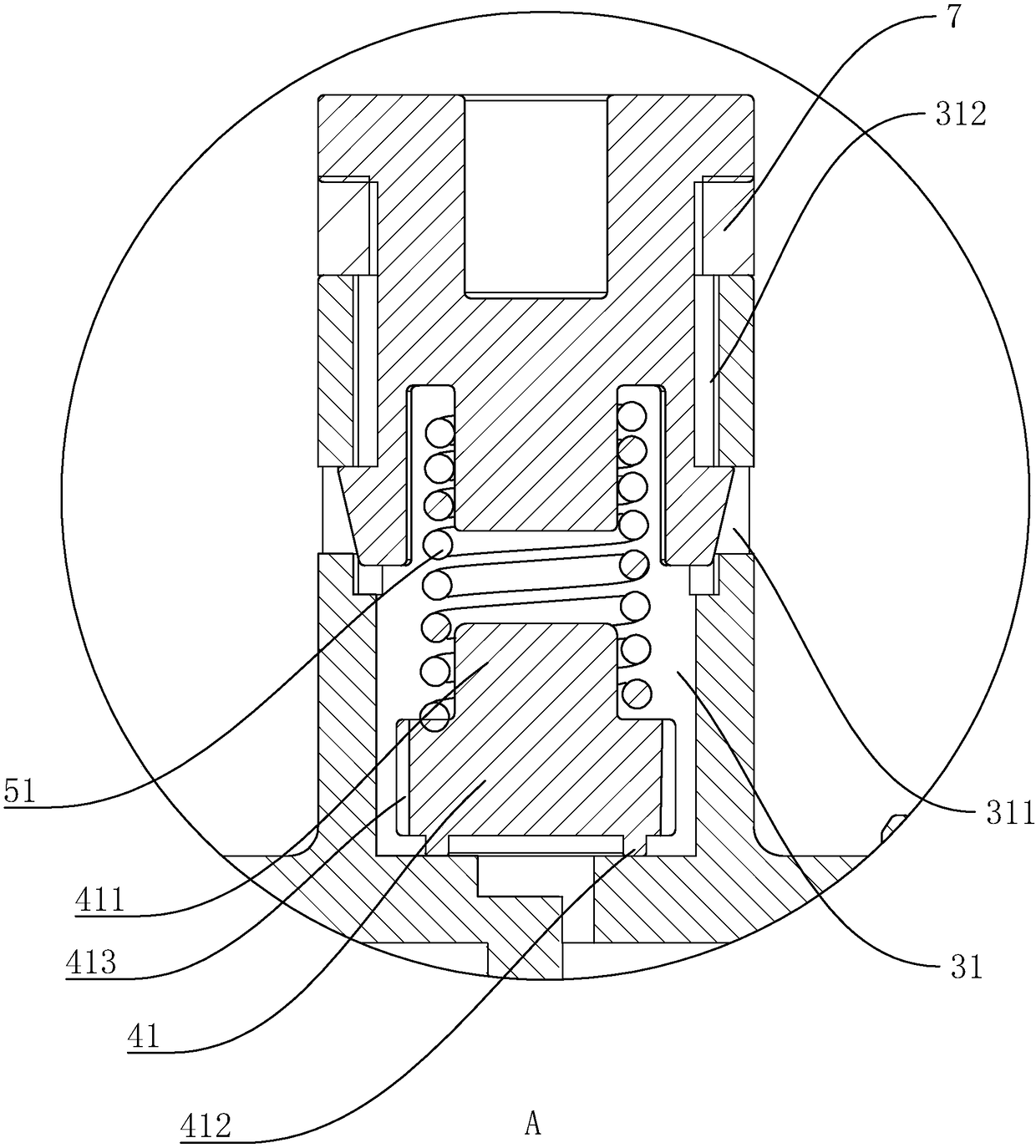

[0037] Such as figure 2 with image 3 所示,弹性件5为弹簧51,密封件4为一密封帽41,卡接件6为一卡扣61。

[0038] 密封帽41为一圆柱,圆柱一端面与泄压口1贴合,另一端面上设有一凸块411,凸块411与弹簧51卡接,密封帽41与泄压底座3的空腔31之间留有一定间隙。

[0039] 卡扣61包括本体611、弹性卡钩612、阻挡块613和限位环614,本体611为一圆柱,本体611一端面延伸有一阻挡块613,另一端面设有两个弹性卡钩612,两个卡爪之间开有限位环614,限位环614与弹簧51连接。

[0040] 泄压底座3侧壁开有与弹性卡钩612相应的卡孔311,泄压底座3背离泄压口1的一侧设有导向槽312,导向槽312与卡孔311相互连通,所述卡爪沿着导向槽312线性运动,与卡孔311相互卡接。

[0041] 安装时,先把密封帽41放入空腔31,套上弹簧51,再把卡扣61的弹性卡勾压缩沿着导向槽312向下滑动,使弹性卡钩612和卡孔311相互卡接 ,finish installation.

[0042] 卡接件6与泄压底座3的间隙之间设有海绵消音环7,消音环7一端抵触泄压底座3端面,另一端抵触阻挡块613的端面。

[0043] 密封帽41贴合泄压口1的一侧设有凸环412,凸环412的直径大于密封口的直径。密封帽4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com