Method for manufacturing solid component and solid component

A technology of solid components and components, applied in the direction of tools, manufacturing tools, bearing components, etc. for lathes, and can solve problems such as high manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

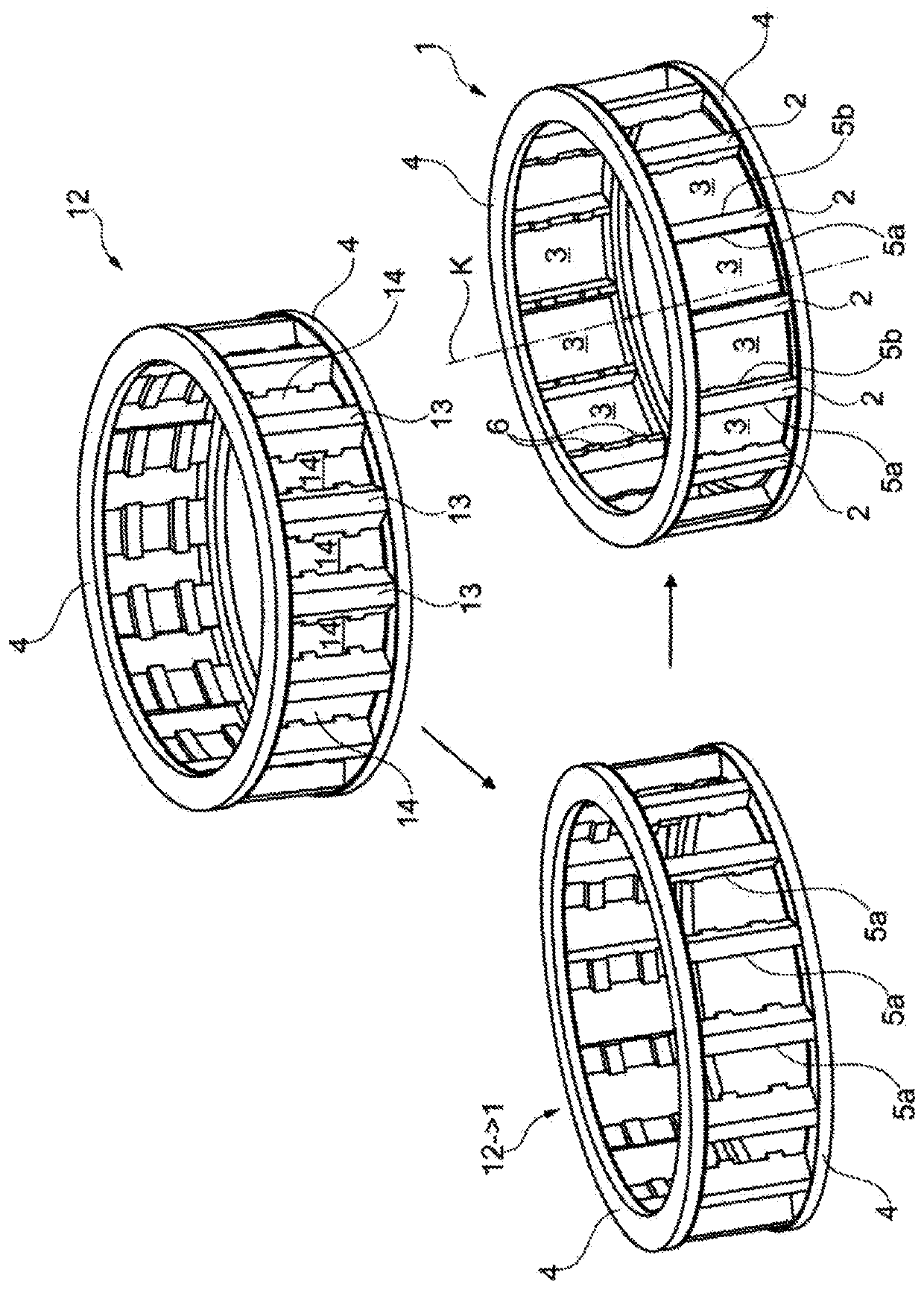

[0044] figure 1 shown for manufacture as in the figure 1 A schematic overview of the method of a solid cage 1 as a solid component is shown at the bottom right. The solid cage 1 is designed for insertion into a rolling bearing and has a plurality of webs 2 as intermediate regions, which are arranged regularly distributed in the circumferential direction about the axis of rotation K of the cage. Between the webs 2 there are respectively pockets 3 for accommodating rolling bodies, which are rollers in this example. Side rings 4 are arranged on the axial end side, wherein the webs 2 and / or the pockets 3 extend between the side rings 4 . The solid cage 1 is formed in one piece.

[0045] Each web 2 has a first web side 5a as the first pocket side and a second web side 5b as the second pocket side. exist figure 1 In the embodiment shown in , the first tab side is oriented clockwise and the second tab side is oriented counterclockwise. For reasons of clarity, only two webs 2 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com